Conductive structure for semiconductor integrated circuit and method for forming the same

A conductive structure and integrated circuit technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of increased equivalent resistance, lower bump plating yield, and affecting plating effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

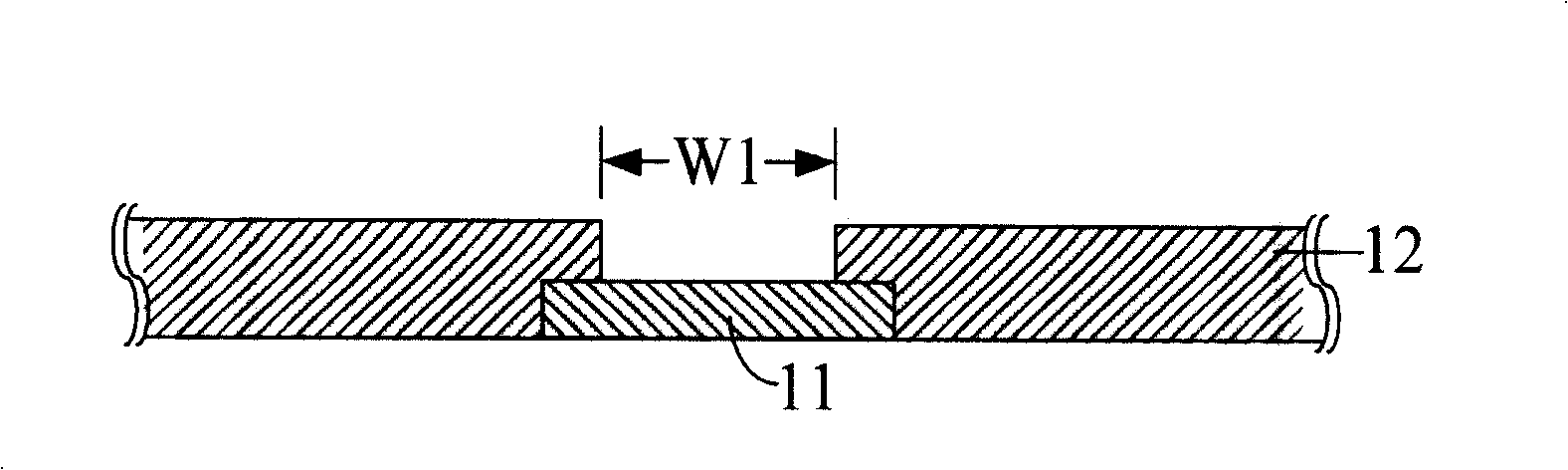

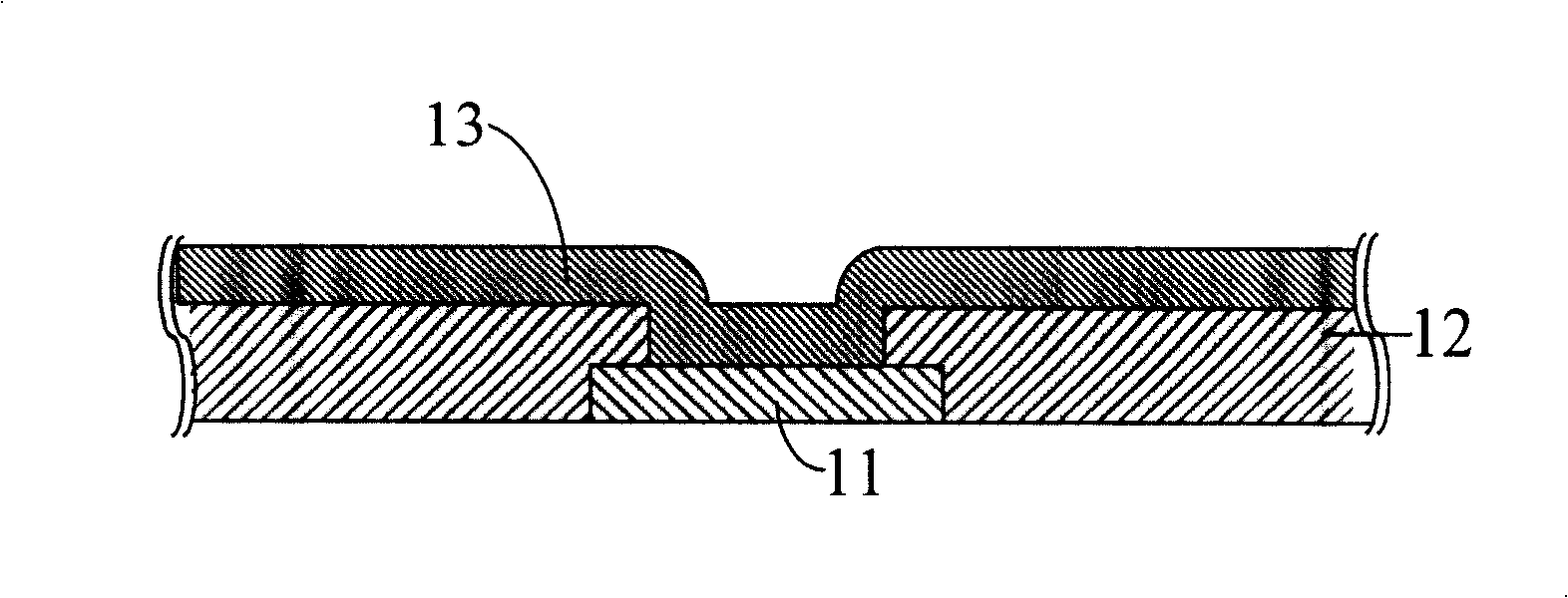

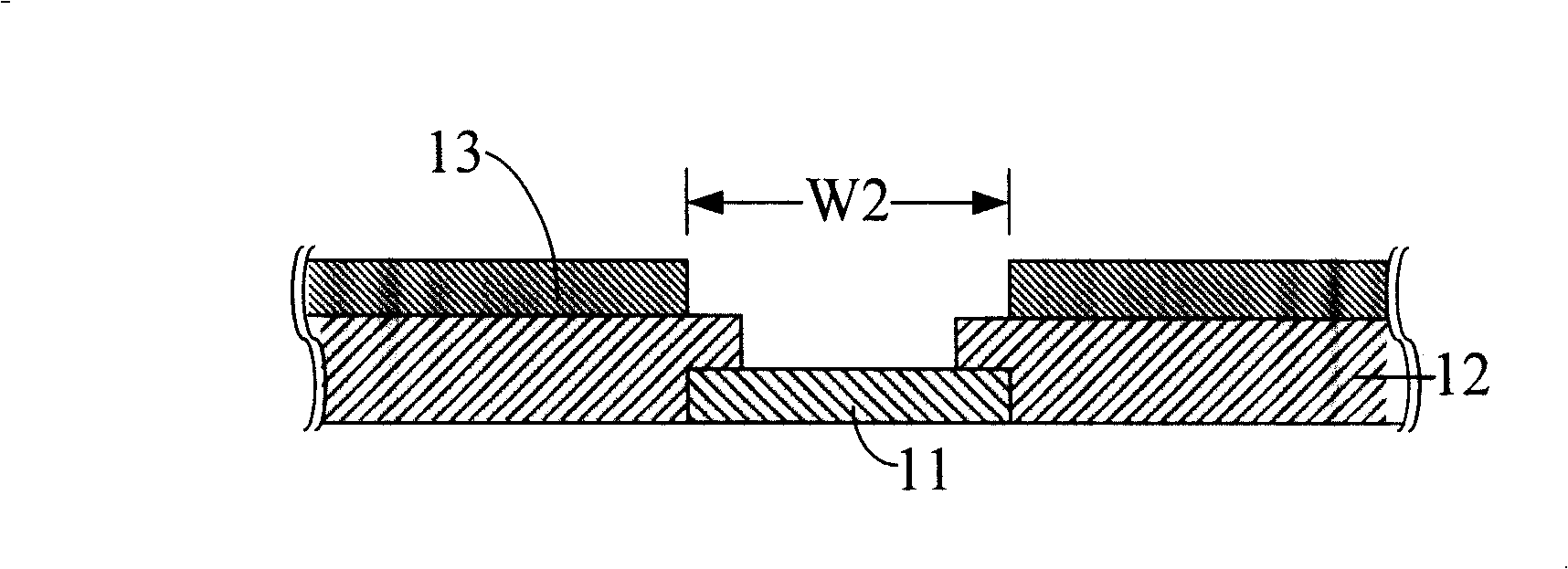

[0012] Figure 1(a) to Figure 1(h) A preferred embodiment of the present invention is shown, which is a schematic flow chart of the formation of a conductive structure for a semiconductor integrated circuit.

[0013] FIG. 1( a ) shows the initial manufacturing process, which firstly forms a liner 11 and a protective layer 12 . In this embodiment, the liner 11 is made of aluminum, and the protective layer 12 partially covers the liner 11, so that the liner 11 is exposed to define a first opening area, which is used as an electrical contact with a bump later. The connection window, wherein the first opening area has a first lateral dimension W1. Since the protective layer 12 covers the edge of the pad 11, the first opening area is smaller than the lateral dimension of the pad.

[0014] Then form a first conductive layer, such as a titanium-tungsten alloy conductive layer 13, which covers the first opening area and extends on the protective layer 12 when it is formed; as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com