Seafood sugar and processing method

A processing method, seafood sugar technology, applied in the confectionary industry, confectionery, food preparation, etc., can solve the problems of complicated process, high cost, and invisible sea cucumbers, etc., achieve the effect of simple production process and increase industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Dry, crush or cut the seafood first to make seafood particles 2 with a particle size of 30 mesh sieves. The seafood can be sea cucumber, abalone, squid or other fish, prawns, scallops, seaweed, seaweed and other seaweed products;

[0022] b. Melt part of the raw materials in the candy base 1, that is, melt the sugar and syrup in the candy bases such as hard, milk fat, gel, gum base, etc. at a temperature of 120-160°C, and add the existing Add some other base materials such as cream, gel or gum base, and add seafood particles 2 to it at the same time, stir to mix evenly and cool;

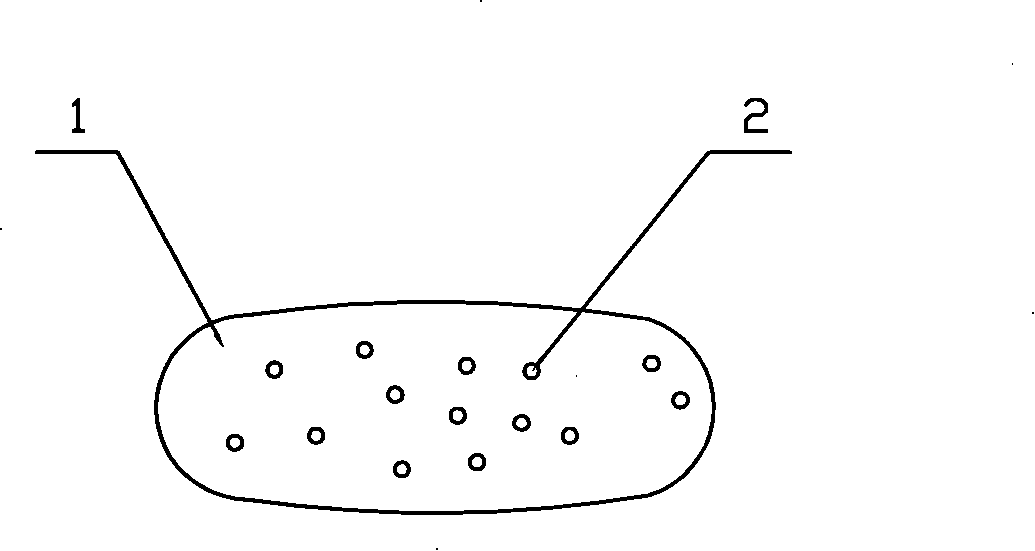

[0023] c. Pour the cooled paste into the mold and press or cast it. i.e. produce as figure 1 Shown is a seafood candy with cooked seafood particles 2 having a particle size of 30 mesh sieve in a candy base 1 . The amount of seafood particles added depends on the taste, usually accounting for 0.14% to 0.57% of the weight of each piece of candy base.

Embodiment 2

[0025] a. Dry, crush or cut the seafood first to make seafood particles 2 with a particle size of 30 mesh sieves. The seafood can be sea cucumber, abalone, squid or other fish, prawns, scallops, seaweed, seaweed and other seaweed products;

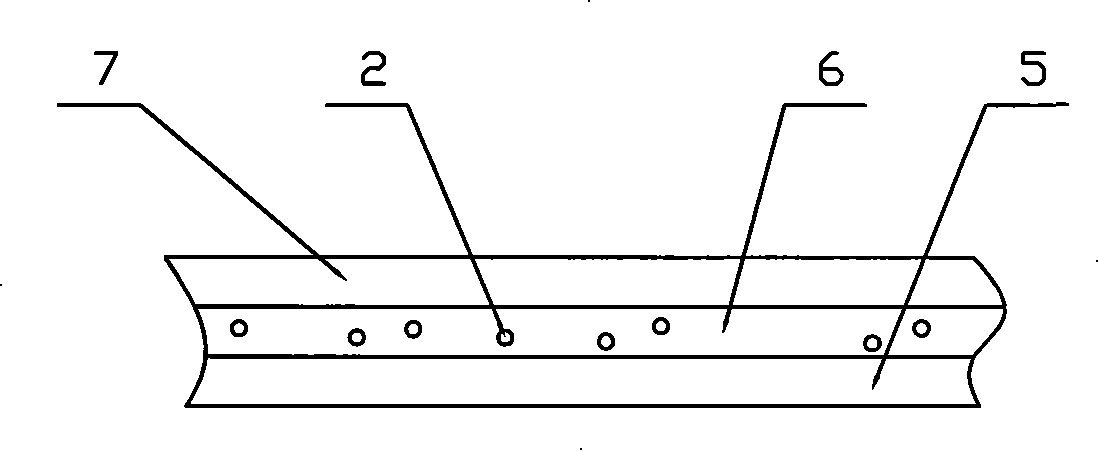

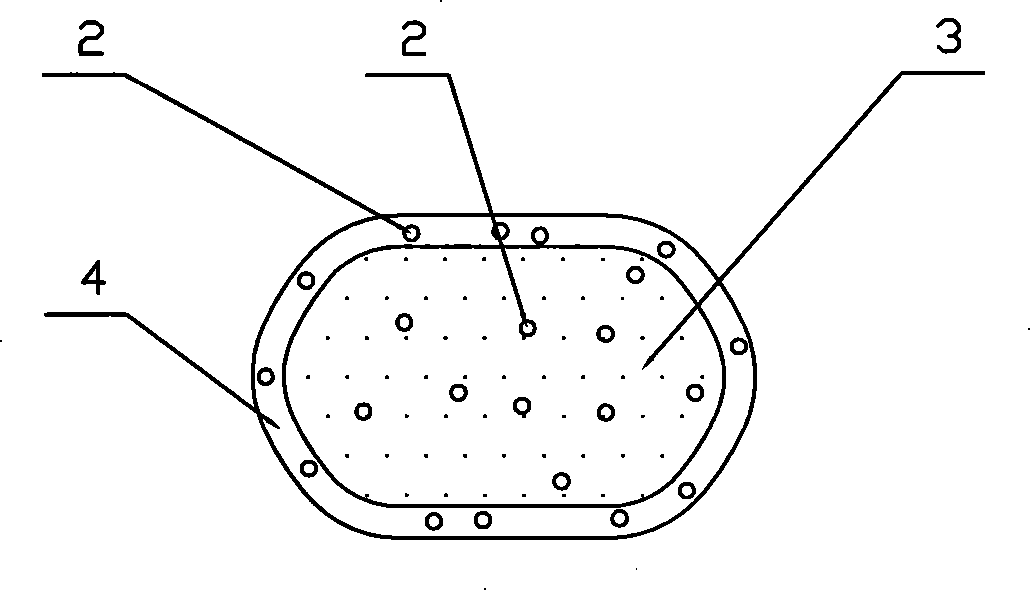

[0026] b. According to the existing production process of crispy candy, first melt sugar and syrup at a temperature of 120-160°C to make liquid syrup; take part of the liquid syrup, crispy seasoning (peanut butter or sesame paste), flour, etc. to make The inner core 3 is ready for use; make it with boiled granulated sugar and syrup liquid such as figure 2 As shown in the three-layered hard candy skin 4 blank, the bottom layer is the white sugar skin 5, the middle is the middle skin 6 mixed with seafood particles 2, the upper layer is the bright skin 7, the white sugar skin 5 and the bright skin 7 The production method is the same as the prior art, except that the middle skin 6 mixed with the seafood particles 2 is mixed with boiled sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com