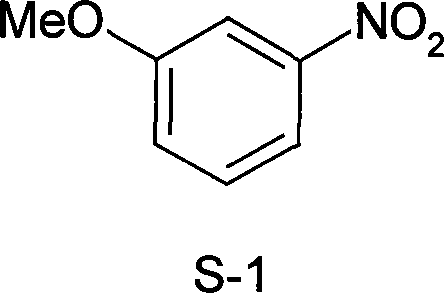

Method for synthesizing 3-methoxy nitrobenzene

A technology of methoxynitrobenzene and synthesis method, which is applied in the field of synthesis of organic compounds, can solve the problems of high price and difficult post-processing, and achieve the effects of reducing costs, increasing output, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

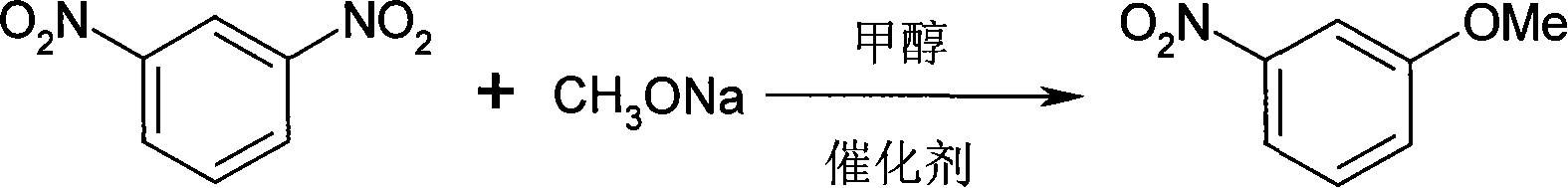

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, a kind of synthetic method of 3-methoxynitrobenzene, carries out following steps successively:

[0015] 1), methoxylation, i.e. the preparation of 3-methoxynitrobenzene crude product:

[0016] 168.0g (1.0mol) m-dinitrobenzene, 135.0g (2.5mol) sodium methylate, 410ml methanol, 0.33g 18-crown-6 ether, 3.36g tetrabutyl bromide were put into an autoclave with stirring and temperature control Ammonium (TBAB), under 1.0 MPa, heated to 150° C. for 10 h to obtain 130.5 g of a dark red solid, which is a crude product of 3-methoxynitrobenzene, and the yield of the crude product was 85.3%.

[0017] 2), recrystallization, i.e. the preparation of 3-methoxynitrobenzene:

[0018] At room temperature, add isopropanol (330 mL) to the above crude 3-methoxynitrobenzene, heat to reflux for 5 h, cool, and vacuum filter. After washing and drying, 121.8 g of white solid was obtained, which was 3-methoxynitrobenzene, and the product yield was 79.6%.

Embodiment 2

[0019] Embodiment 2, a kind of synthetic method of 3-methoxynitrobenzene, carry out following steps successively:

[0020] 1), methoxylation, i.e. the preparation of 3-methoxynitrobenzene crude product:

[0021] 33.6g (0.2mol) m-dinitrobenzene, 21.6g (0.4mol) sodium methoxide, 80ml methanol, 0.02g18-crown-6 ether, 0.17g tetrabutyl bromide were put into the autoclave with stirring and temperature control Ammonium (TBAB), heated at 0.5 MPa to 100° C. for 6.5 h to obtain 26.9 g of a dark red solid, which is a crude product of 3-methoxynitrobenzene, and the yield of the crude product is 87.9%.

[0022] 2), recrystallization, i.e. the preparation of 3-methoxynitrobenzene:

[0023] At room temperature, add n-propanol (100 mL) to the crude 3-methoxynitrobenzene, heat to reflux for 2 h, cool, and vacuum filter. After washing and drying, 25.6 g of white solid was obtained, which was 3-methoxynitrobenzene, and the product yield was 83.6%.

Embodiment 3

[0024] Embodiment 3, a kind of synthetic method of 3-methoxynitrobenzene, carries out following steps successively:

[0025] 1), methoxylation, i.e. the preparation of 3-methoxynitrobenzene crude product:

[0026] 84.0g (0.5mol) m-dinitrobenzene, 34.0g (0.63mol) sodium methylate, 300ml methanol, 0.08g 18-crown-6 ether, 0.84g tetrabutyl bromide were put into the autoclave with stirring and temperature control Ammonium (TBAB), heated at 0.65MPa to 120°C for 5h to obtain 72.7g of a dark red solid, which is a crude product of 3-methoxynitrobenzene, and the yield of the crude product is 95.0%.

[0027] 2), recrystallization, i.e. the preparation of 3-methoxynitrobenzene:

[0028] At room temperature, ethanol (180 mL) was added to the crude 3-methoxynitrobenzene, heated to reflux for 1 h, cooled, and vacuum filtered. After washing and drying, 69.4 g of white solid was obtained, which was 3-methoxynitrobenzene, and the product yield was 90.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com