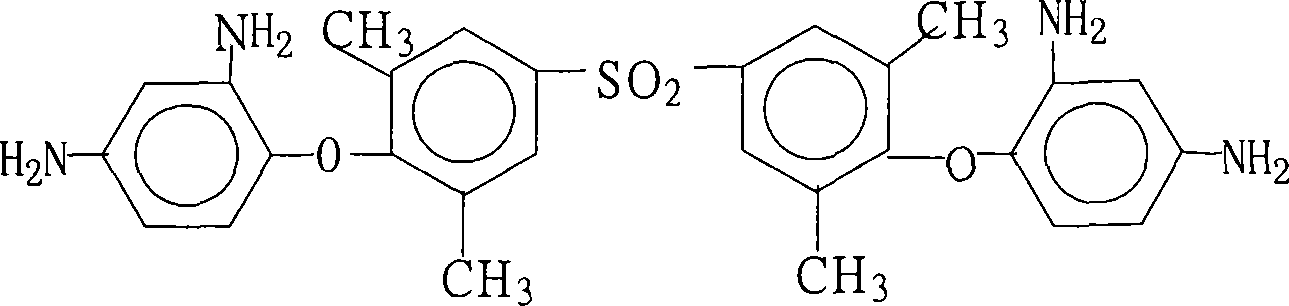

Method for preparing 4,4'-di(2,4-diamino phenoxy)-3,3',5,5'-tetramethyl diphenyl sulfone

A technology of tetramethyldiphenyl sulfone and diaminophenoxy, which is applied in 4 fields, can solve the problems of no patents and literature reports on the preparation method, and achieve the effects of convenient source of raw materials, less waste, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

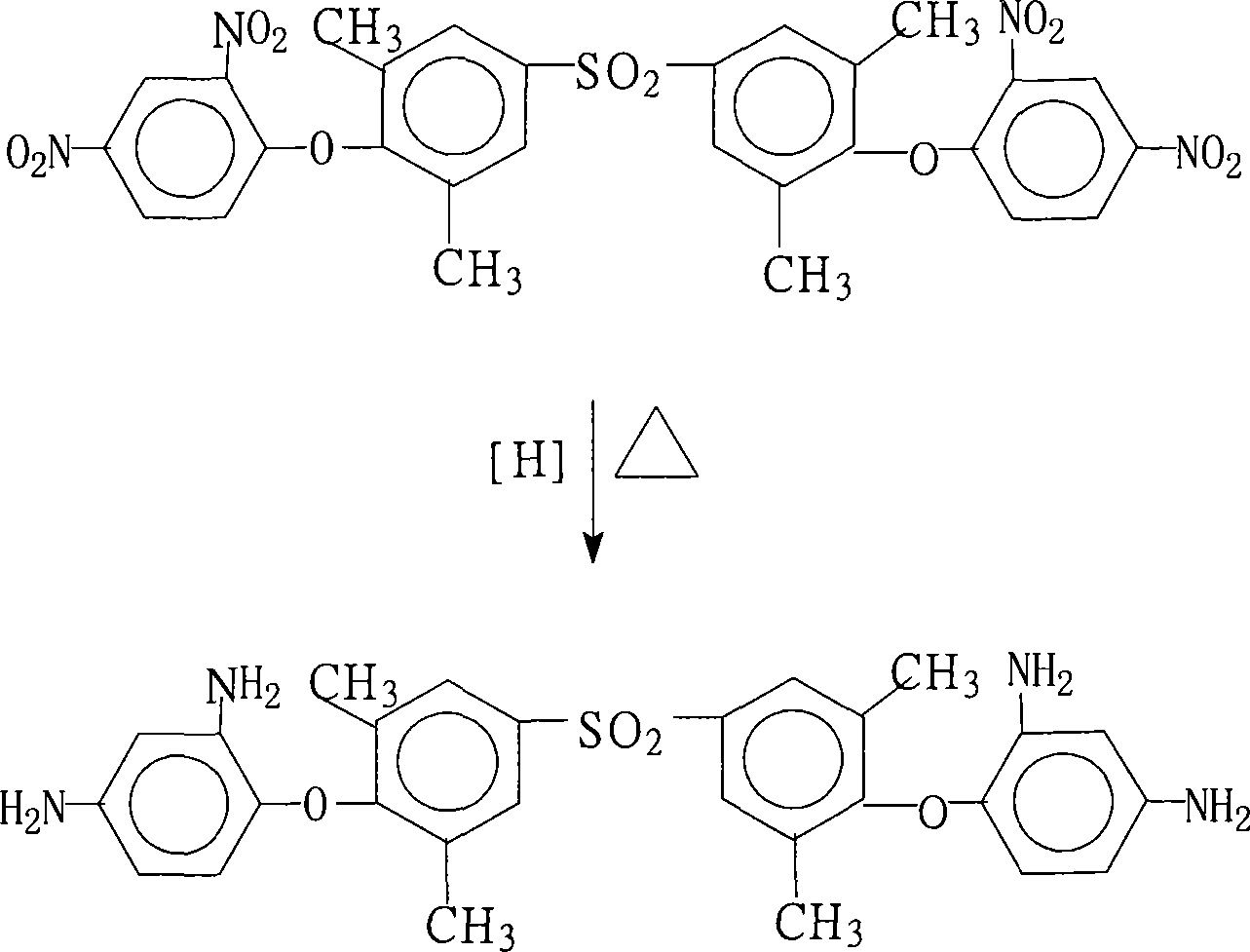

Method used

Image

Examples

Embodiment 1

[0027] 63.8 grams (0.1 moles) of 4,4'-bis(2,4-dinitrophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone, 0.7 grams of palladium with a mass percentage of 15 % palladium / charcoal, 1800 milliliters of ethanol and 1800ml ethylene glycol add in the reaction flask, stir, heat up to 60 ℃, start to drip the hydrazine hydrate solution that mass concentration is 60% (hydrazine hydrate molecular weight is 50.06), altogether 250.0 grams ( solution weight). After the dropwise addition of hydrazine hydrate was completed, the stirring reaction was continued for 3.5 hours at a temperature range of 80°C to 90°C, cooled slightly, filtered while hot, cooled mother liquor, added pure water, precipitated crystallized product, filtered, and vacuum-dried to obtain 42.8 grams of 4 , 4'-bis(2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone crystal with a purity of 99.5%, according to the actual obtained 4,4'-bis (2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone amount and theoretical amoun...

Embodiment 2

[0029] 63.8 grams (0.1 mole) of 4,4'-bis(2,4-dinitrophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone, 12.0 grams of palladium mass percentage of 1 % palladium / charcoal, 100ml ethylene glycol and 5800ml ethanol are added in the reaction flask, stirred, heated to 60° C., and the dropwise addition of mass concentration is 85% hydrazine hydrate solution, totally 294.1 grams (solution weight). After the dropwise addition of hydrazine hydrate was completed, the stirring reaction was continued for 5 hours in the temperature range of 80°C to 90°C, cooled slightly, filtered while hot, cooled mother liquor, added pure water, precipitated crystalline product, filtered, and vacuum-dried to obtain 43.3 grams of 4 , 4'-bis(2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone crystal with a purity of 99.2%, according to the actual obtained 4,4'-bis (2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone amount and theoretical amount (51.8 grams), calculated to obtain 4,4'-bis(2,4 The yie...

Embodiment 3

[0031] 63.8 grams (0.1 moles) of 4,4'-bis(2,4-dinitrophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone, 7.8 grams of palladium with a mass percentage of 5 % palladium / charcoal, 600 milliliters of ethanol and 3600ml 2-methoxyethanol are added in the reaction flask, stirred, heated up to 60 ℃, start to drip the hydrazine hydrate solution that mass concentration is 80%, totally 260.0 grams (solution weight) . After the addition of hydrazine hydrate was completed, the stirring reaction was continued at a temperature range of 80°C to 90°C for 5 hours, cooled slightly, filtered while hot, cooling the mother liquor, adding pure water to precipitate a crystalline product, filtering, and vacuum drying to obtain 44.0 g of 4 , 4'-bis(2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone crystal, the purity is 99.7%, according to the actual obtained 4,4'-bis (2,4-diaminophenoxy)-3,3',5,5'-tetramethyldiphenylsulfone amount and theoretical amount (51.8 grams), calculated to obtain 4,4'-bis(...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap