Microelectrode array chip for cell electrofusion

A technology of microelectrode array and electrode array, which is applied in the direction of hybrid cell preparation, stress-stimulated microbial growth method, biochemical equipment and method, etc., can solve the problems of unfavorable sample liquid entry and exit and later cultivation, weak electric field strength and electric field gradient, Anti-corrosion, weak anti-oxidation ability and other problems, to achieve the effect of improving the internal electric field distribution, reducing physical damage, and ensuring biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

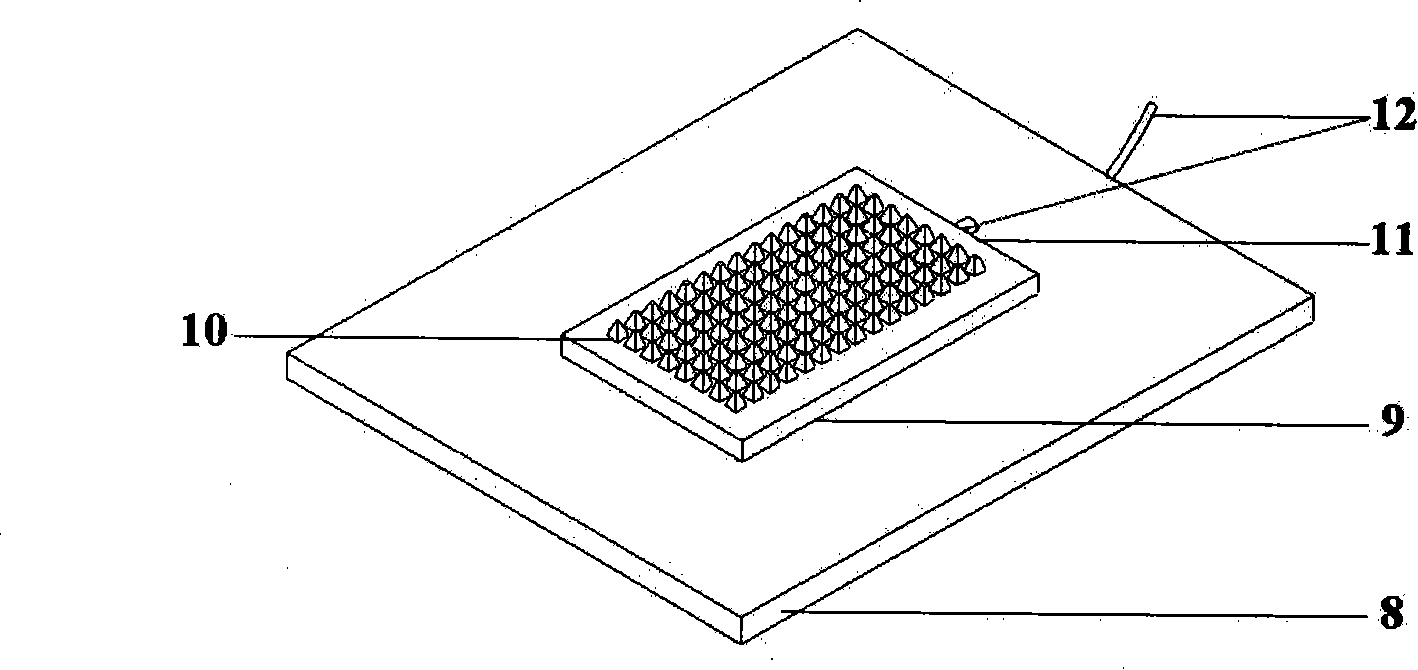

[0031] First, bond a layer of silicon wafer material on the surface of hard insulating chip processing materials such as glass, and use MEMS processing technology to etch grooves with a certain depth on the silicon wafer to form a silicon microelectrode array, and deposit platinum on the electrode surface Inert metal materials such as metals improve corrosion resistance and biocompatibility, and connect the microelectrode array with peripheral circuits through metal leads to introduce electrical signals. The fusion cell containing the sample solution is formed by etching a rectangular groove for hard conductive chips such as metals. In the experiment, the microelectrode array is immersed in the sample solution,

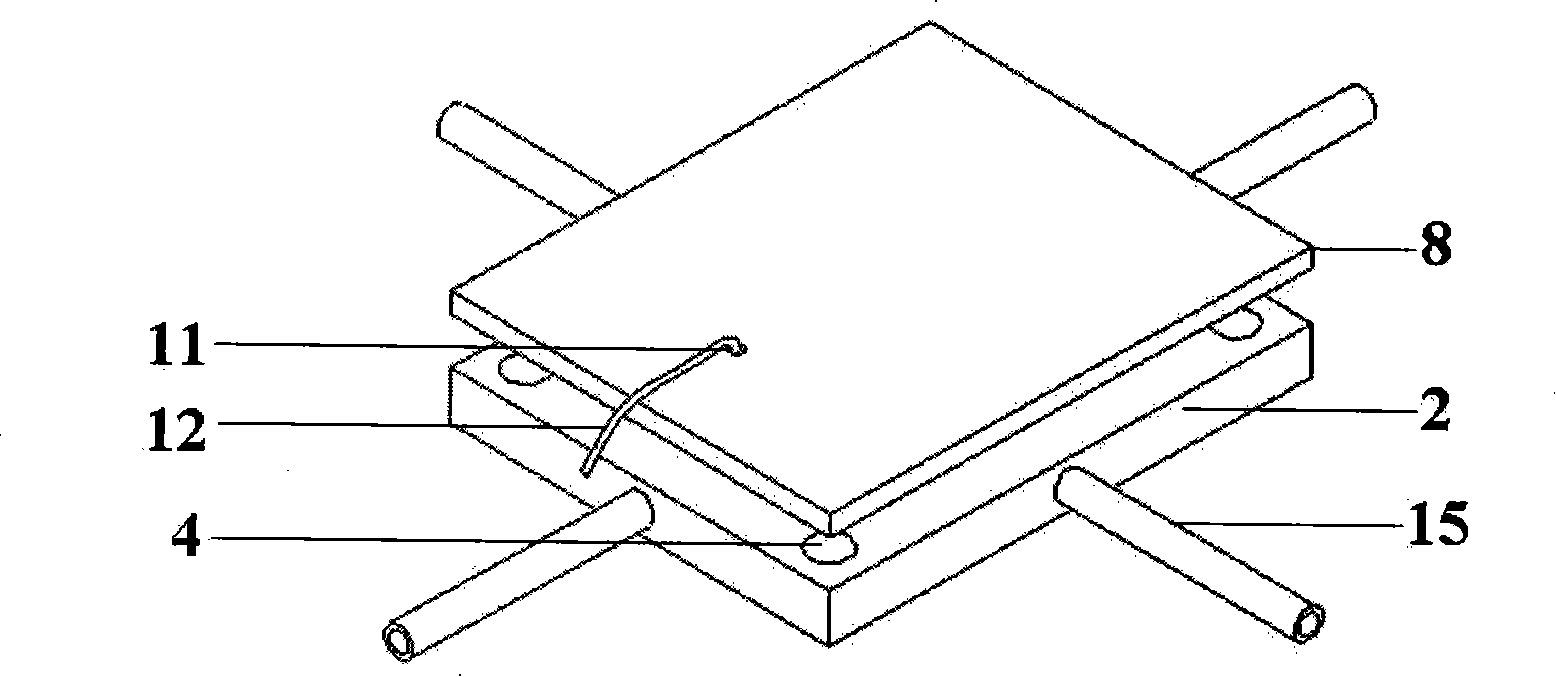

[0032] see figure 1 , the microelectrode array chip is composed of two mutually independent modules, namely the microelectrode array module A and the fusion pool and plate electrode module B.

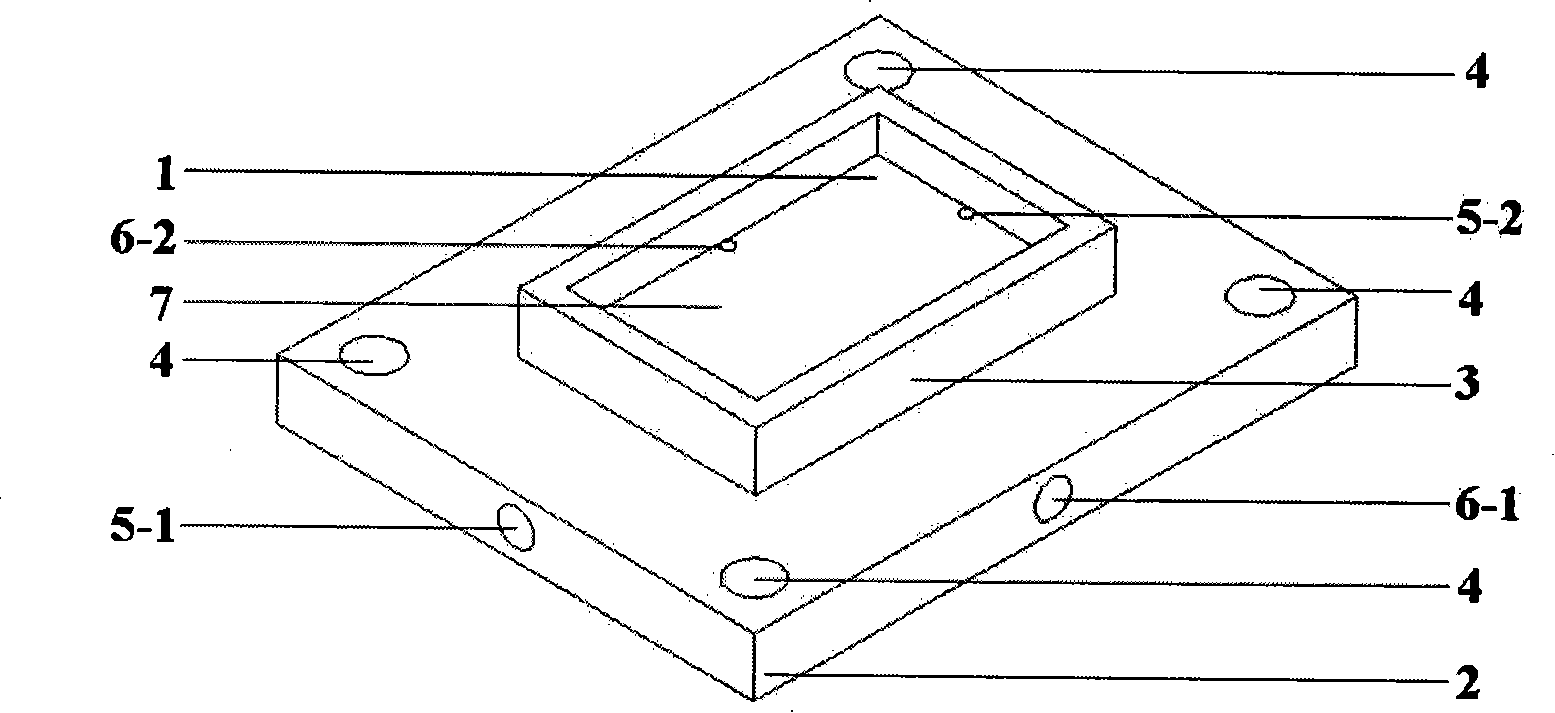

[0033] see in conjunction figure 2 , the fusion cell and the flat elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com