Top burning hot blast stove with slope-ladder shaped circumferential loop up-spraying ceramic combustor

A technology of ceramic burners and hot blast stoves, applied in furnaces, blast furnaces, heating furnaces, etc., can solve problems such as uneven nozzle pressure, short service life, and uneven nozzle pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

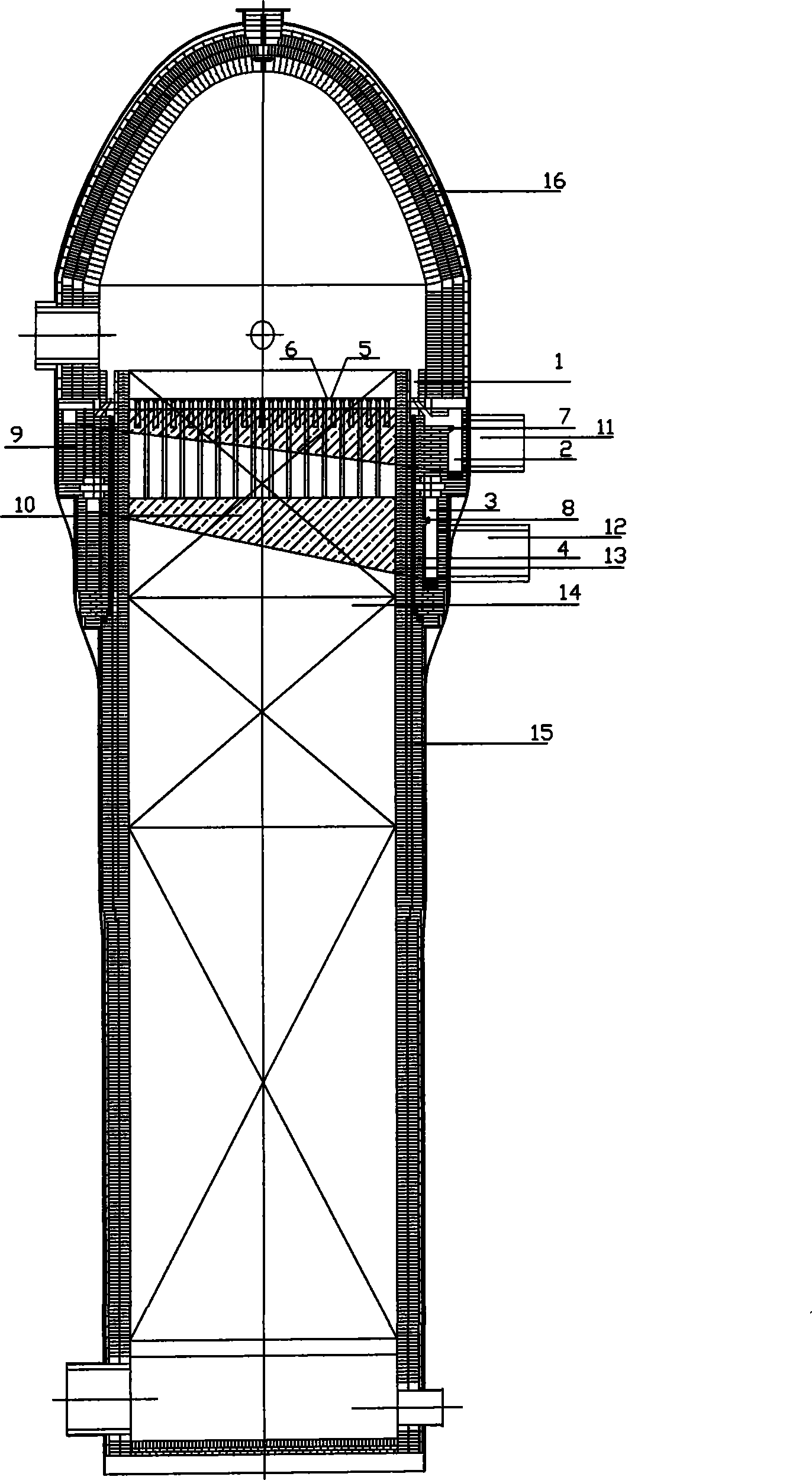

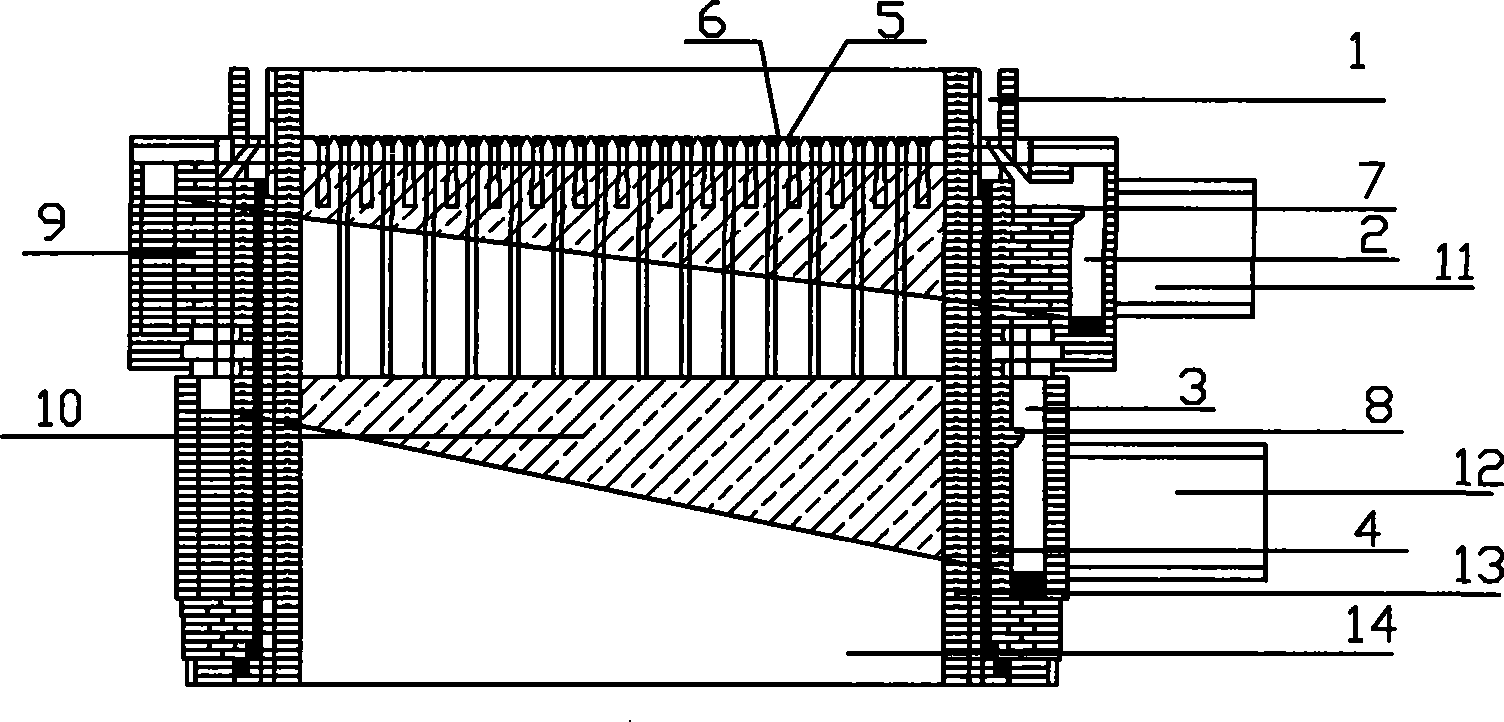

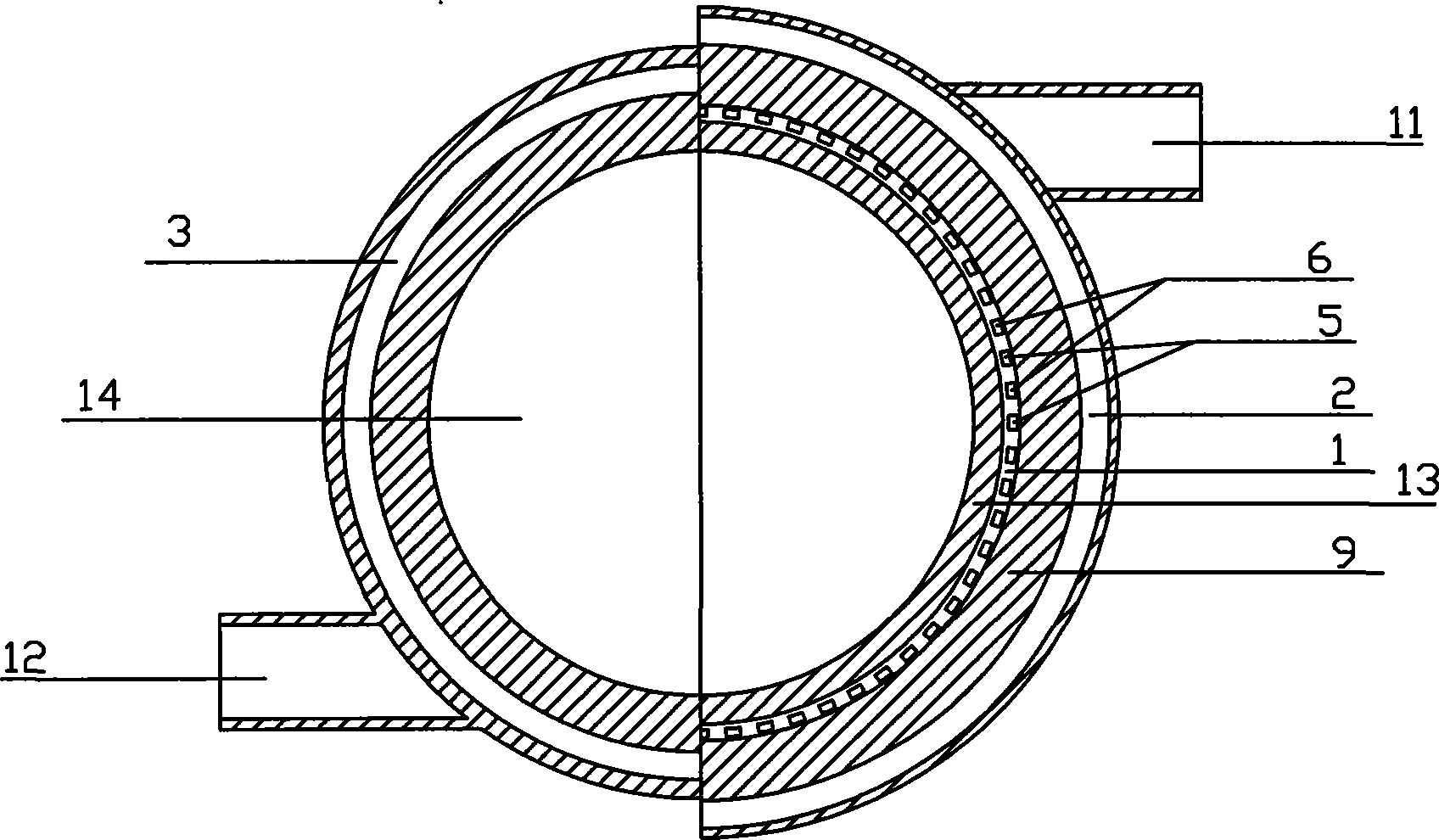

[0008] Depend on figure 1 , figure 2 Shown, the present invention comprises furnace body 15, dome 16 and ceramic burner, and ceramic burner is placed on the furnace body top below dome, and said ceramic burner has burner body of wall 9, gas preheating loop 2. Combustion-supporting air preheating loop 3, gas preheating loop 2, combustion-supporting air preheating loop 3 are respectively connected with air nozzles 5 and 6, which are arranged staggered at 30-80° on the upper part of the combustion air preheating loop, and the gas is preheated The ring and the combustion air preheating ring are in the shape of a symmetrical uphill and downhill ladder 10, arranged in the wall of the burner, and a circumferential annular preheating channel 1 is arranged in the wall on the top of the burner, and is connected with The gas and air noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com