Apparatus and method for testing resistance dew-point corrosion of evaluating material

A dew point corrosion and testing device technology, applied in measurement devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of inability to correctly evaluate the dew point corrosion resistance of materials, and achieve the effect of simple structure and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with example further clarifies content of the present invention, but example is not limited in protection scope of the present invention.

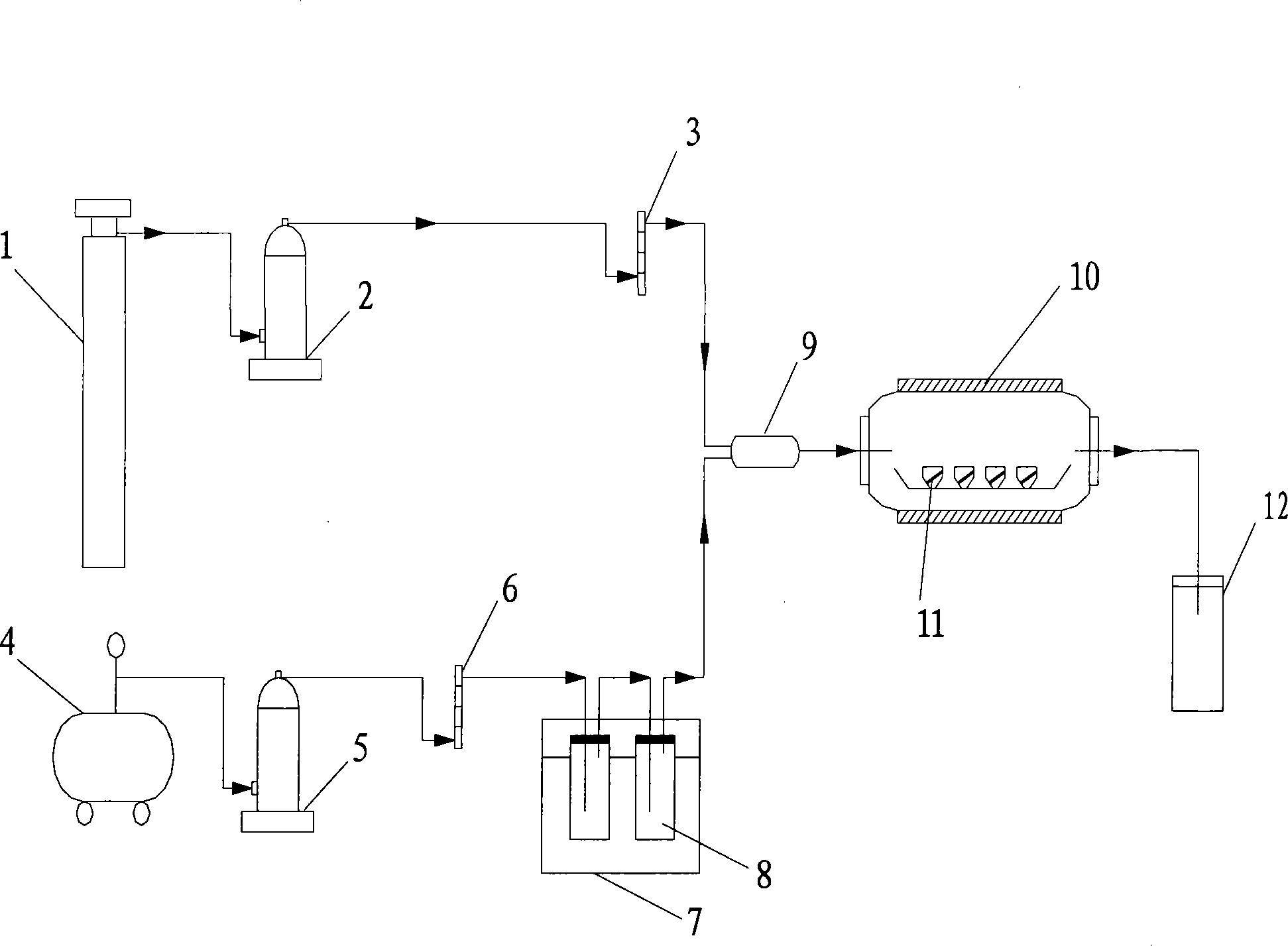

[0017] The evaluation device in the present invention is used to test the performance of four metal materials, 20g carbon steel, austenitic stainless steel 304, 317 and duplex stainless steel 2205, against sulfuric acid dew point corrosion.

[0018] The air flow rate is 1L / min, SO 2 The gas flow rate is 20ml / min, the temperature of the constant temperature water bath is controlled at 75°C, the temperature of the heating furnace is controlled at 115°C, and the corrosion medium in the furnace is 80% by mass, 10ml concentrated sulfuric acid + 2g activated carbon.

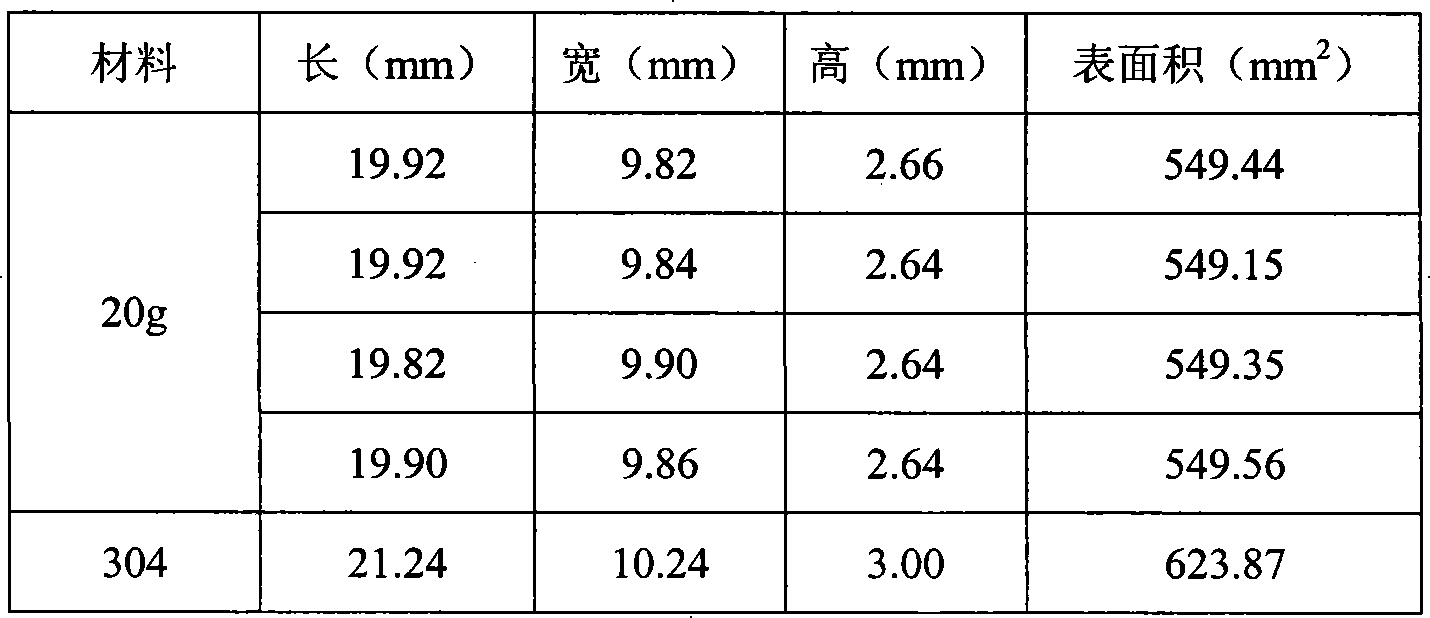

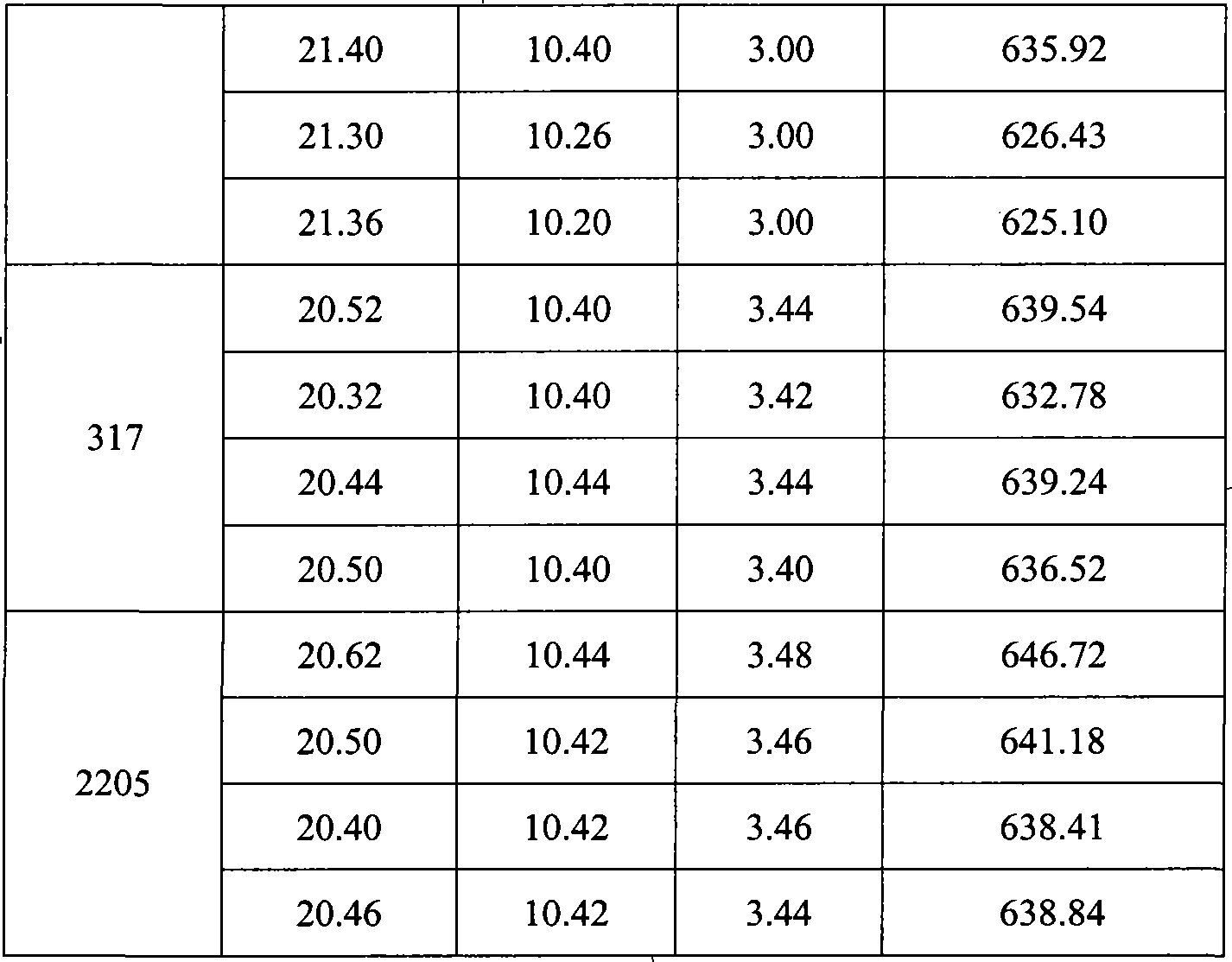

[0019] Four parallel samples were prepared for each material, and the surface of the samples was polished with sandpaper, cleaned with acetone, and then weighed. The shape and size of the samples are shown in Table 1.

[0020] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com