High-efficiency low energy consumption desulfurized dust removing equipment

A desulfurization and dust removal equipment, low energy consumption technology, applied in lighting and heating equipment, combustion product treatment, combustion method and other directions, can solve the problems of inconvenient installation and disassembly, inconvenient construction, low dust removal efficiency, etc., to save equipment space, installation and disassembly, etc. Convenient, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

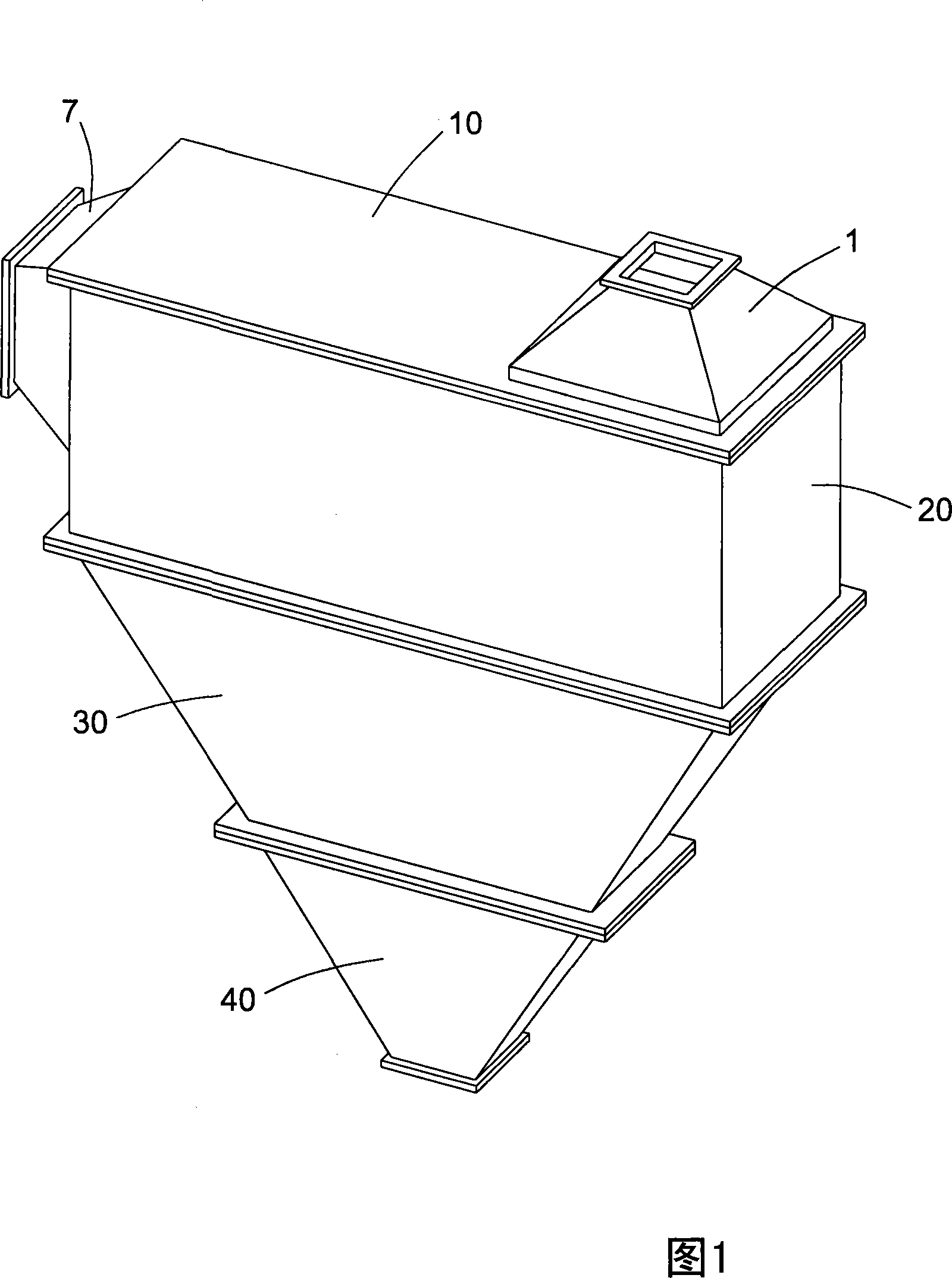

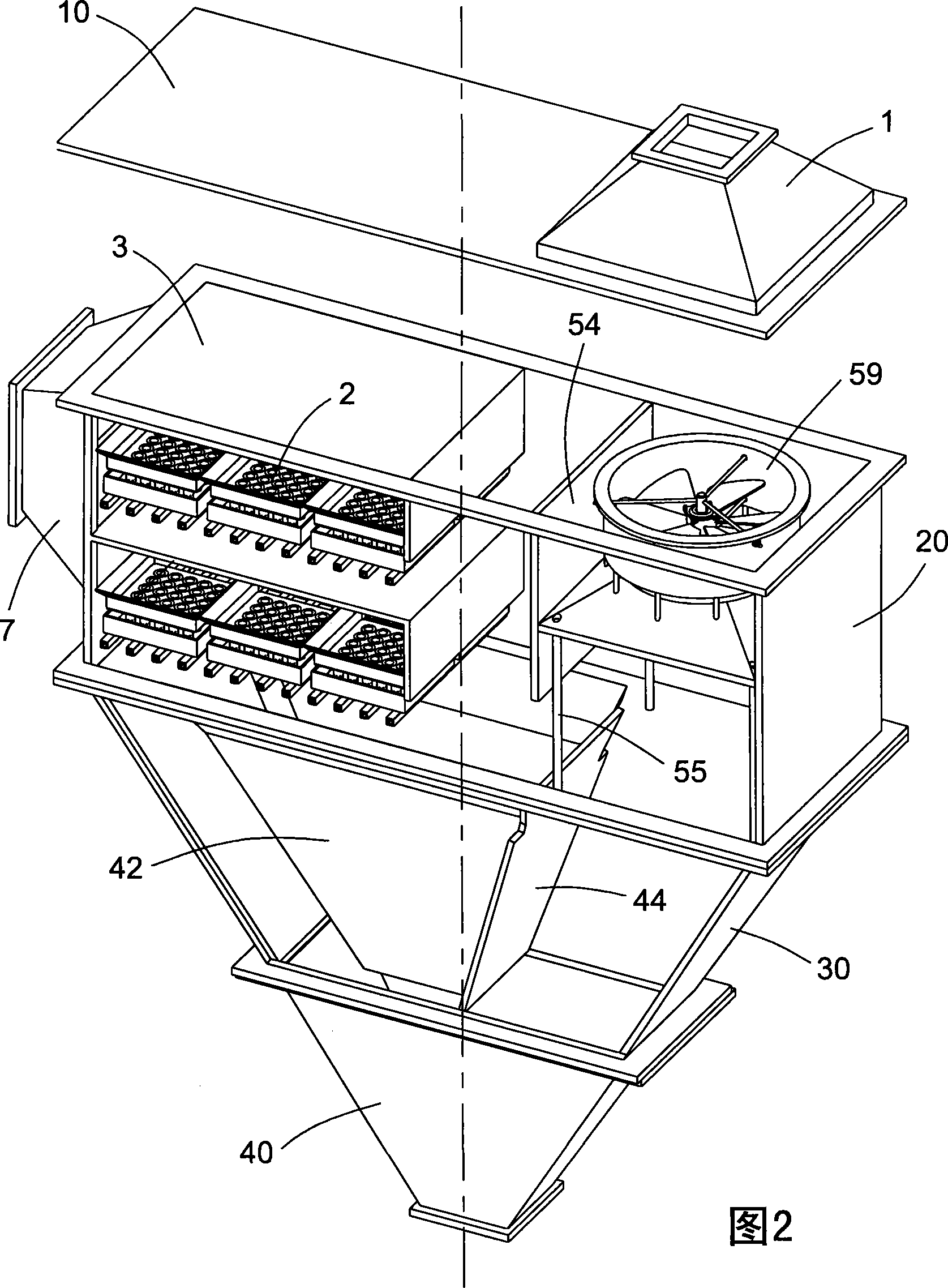

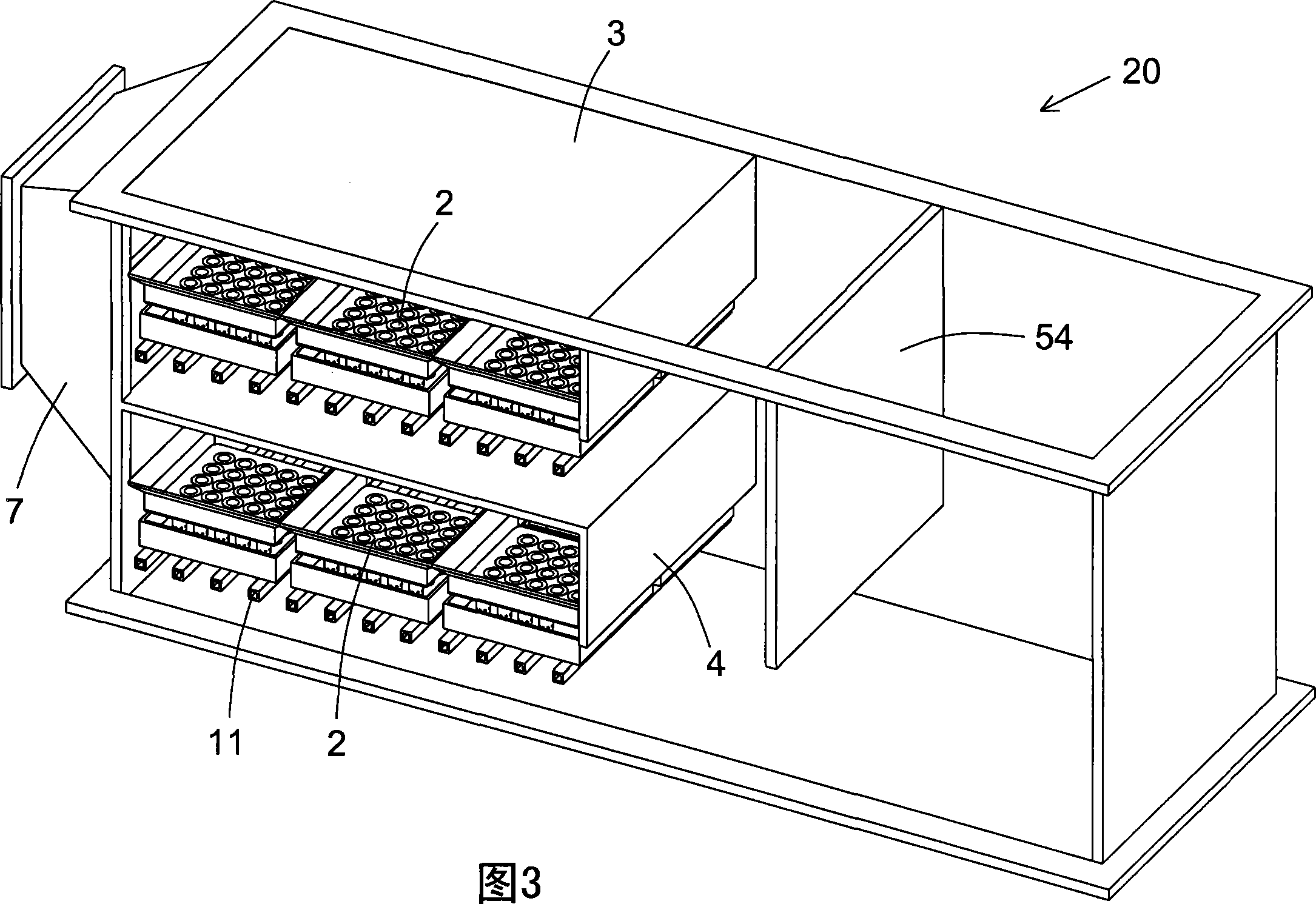

[0047] part number

[0048] 1Exhaust port 2Screen tube 3Spray chamber 4Spray chamber

[0049] 5 sieve plate 6 guide tube 7 air inlet

[0050] 8 horizontal fence 9 vertical fence 10 top cover 11 bracket

[0051] 12 water bath overflow box 13 water spray pipe or nozzle 14 water spray pipe or nozzle

[0052] 15 round holes 16 through holes 17 slots

[0053] 18 flanging 19 flanging 20 water bath purification box

[0054] 21 shell 22 middle shaft 23 impeller

[0055] 24 upper support rod 25 lower support rod 26 nut

[0056] 27 Nut 28 Blade 29 Hub 30 Settling box

[0057] 31 Steam confluence cover 32 Suspension rod 33 Leakage hole 34 Diversion cap

[0058] 35 bearing 36 bearing 37 positioning boss

[0059] 38 upper end cover 39 lower end cover 40 mud box 41 box body

[0060] 42 Left baffle 43 Right baffle 44 Rear blocking plate

[0061] 45 Folded Edges 46 Folded Edges 47 Water Flow Channels 48 Water Flow Channels

[0062] 49 Gap 50 Thick slurry pump 51 Gap 52 Clean water ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com