Deep borehole drawing-boring machine tool

A deep hole and machine tool technology, applied in the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low machining accuracy, low rigidity of boring bar, rough surface, etc. The effect of bending deformation resistance, ensuring machining accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

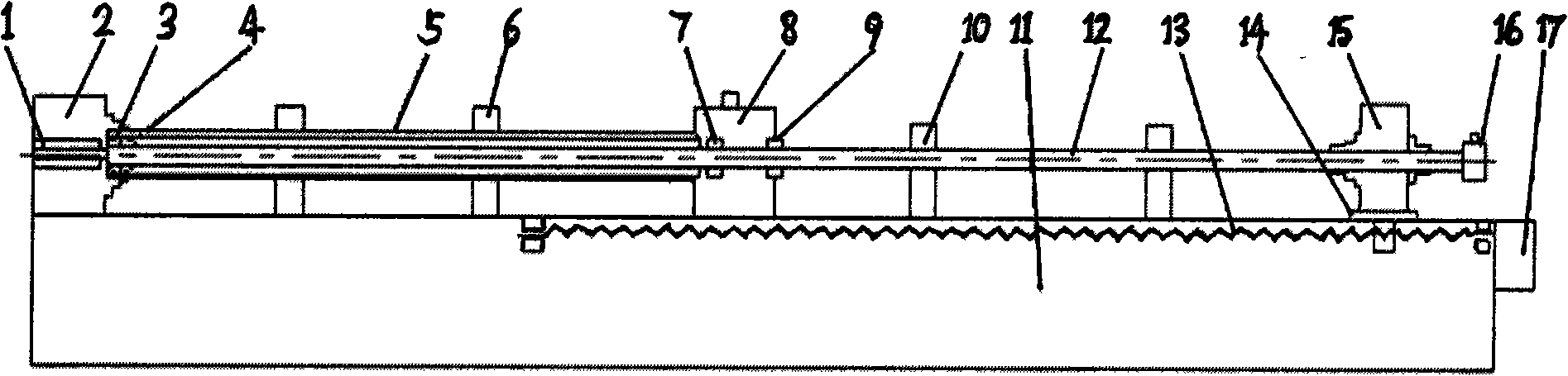

[0007] Such as figure 1 As shown, the present invention is a drawing and boring machine tool for processing deep holes of slender tubes. It includes a body 11, a headstock 2, a centering bracket 6, an oil applicator 8, a front support 7, and a rear oil applicator. Support 9, boring tool front support 1, boring bar 12, boring bar support frame 10, rotary joint 16, pallet 14, boring bar drive box 15, feed screw 13 and tool feed drive box 17, headstock 2 is installed in On the left end of the fuselage 11, the boring tool front support 1 is fixed in the spindle box along the main axis AA′. The centering bracket 6 is fixed on the fuselage 11, and the oil applicator 8 is fixed at the end of the workpiece in the middle of the fuselage 11 for boring tools. 3 for cooling and lubrication, the front support 7 of the oil applicator and the rear support 9 of the oil applicator are fixedly connected to the front side of the oil applicator 8 along the main axis AA′ direction, and the boring bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com