Technique for producing toasted garlic polysaccharides and allinase by using toasted garlic as raw material

A garlic polysaccharide and production process technology, applied in the direction of lyase, can solve the problem of no industrial production of alliinase, etc., and achieve high production and application value, simple method, and high recovery of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

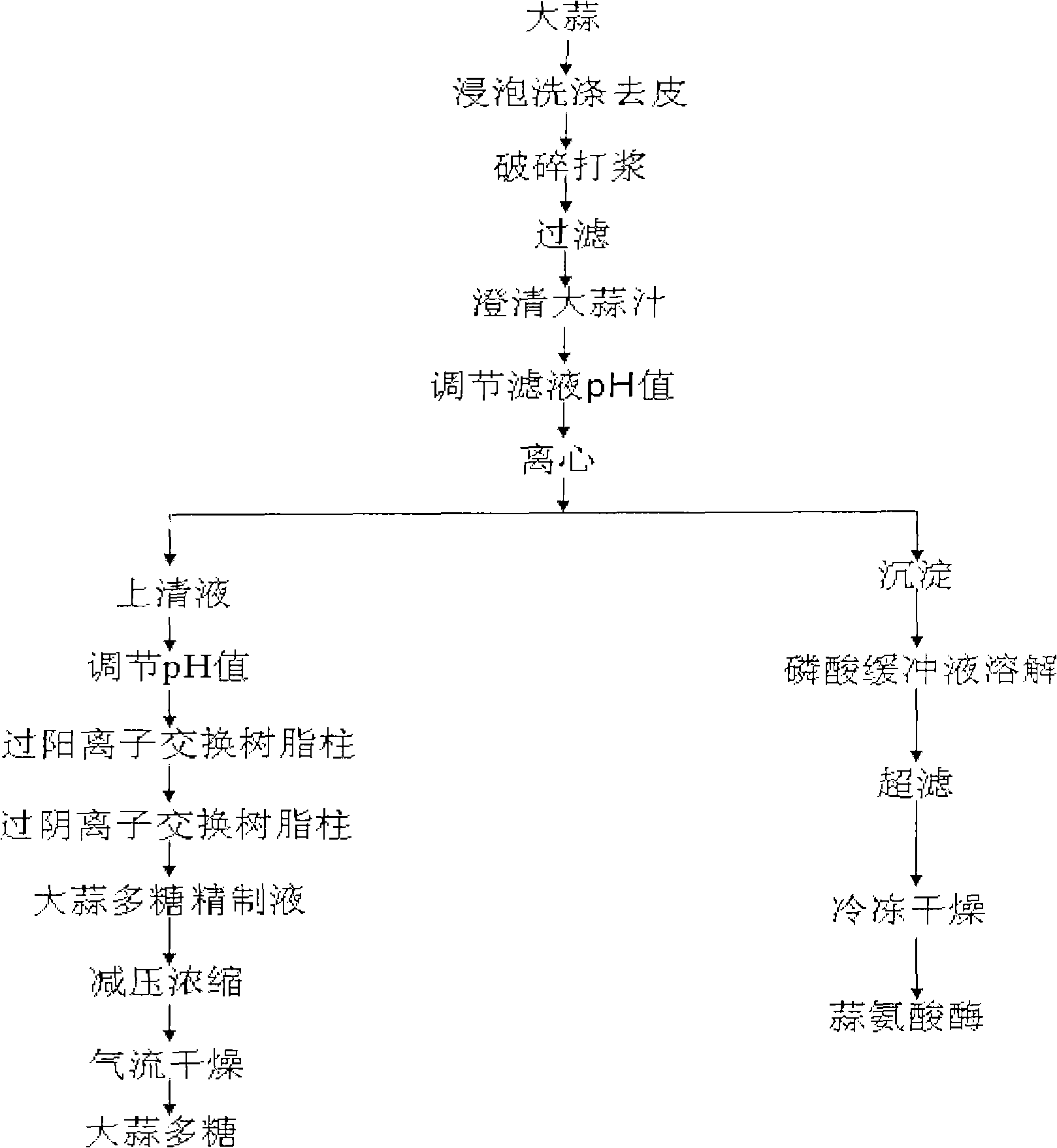

Method used

Image

Examples

Embodiment 1

[0030] Using fresh garlic as raw material, the method for jointly preparing alliinase and garlic polysaccharide is specifically carried out according to the following steps:

[0031] The first step is pretreatment: put fresh garlic cloves in drinking water whose quality is about 6 times its mass, soak for 2 hours, wash and peel in running water, control dry clear water, put it in a beater and crush it into garlic pulp with a particle size of 200 mesh . Garlic pulp is squeezed and filtered with a plate filter. Wash the filter residue with water for 2-3 times, combine the filtrate, and take the filtrate for later use.

[0032] The second step is to separate alliinase: add food-grade hydrochloric acid dropwise to the obtained garlic extract, and stir rapidly to reduce the pH of the extract to 3.0, centrifuge, and dissolve the obtained precipitate with a phosphate buffer solution with a pH of 6. , using various ultrafiltration membranes with a molecular weight cut-off of 30,000 ...

Embodiment 2

[0036] Using fresh garlic as raw material, the method for jointly preparing alliinase and garlic polysaccharide is specifically carried out according to the following steps:

[0037] The first step is pretreatment: put fresh garlic cloves in drinking water whose quality is about 4 times its mass, soak for 2 hours, wash and peel in running water, control dry clear water, put it on a beater and crush it into garlic pulp with a particle size of 300 mesh. Garlic pulp is squeezed and filtered with a plate filter. Wash the filter residue with water for 2-3 times, combine the filtrate, and take the filtrate for later use.

[0038] The second step is to separate alliinase: add phosphoric acid dropwise to the obtained garlic extract, and stir rapidly to reduce the pH of the extract to 5.0, centrifuge, and the obtained precipitate is dissolved in a phosphate buffer solution with a pH of 6. Various ultrafiltration membranes with a molecular weight cut-off of 30,000 to 60,000 Daltons are...

Embodiment 3

[0042] Using fresh garlic as raw material, the method for jointly preparing alliinase and garlic polysaccharide is specifically carried out according to the following steps:

[0043] The first step is pretreatment: put fresh garlic cloves in drinking water whose quality is about 3 times its mass, soak for 2 hours, wash and peel in running water, control dry clear water, put it on a beater and crush it into garlic pulp with a particle size of 300 mesh. Garlic pulp is squeezed and filtered with a plate filter. Wash the filter residue with water for 2-3 times, combine the filtrate, and take the filtrate for later use.

[0044] The second step is to separate alliinase: add citric acid or lactic acid drop by drop to the garlic extract, and stir quickly to reduce the pH of the extract to 4, centrifuge, and dissolve the obtained precipitate with a phosphate buffer solution with a pH of 7 , using various ultrafiltration membranes with a molecular weight cut-off of 30,000 to 60,000 Da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com