Device for controlling a component of an electronic board and activation system comprising same

A technology for controlling equipment and printed circuit boards, which is applied to a part of electrical equipment, coding switches, and assembly components such as electronic tripping systems. It can solve problems such as limited fit options, frequent space, and restrictions, and achieve increased machining and alignment. effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

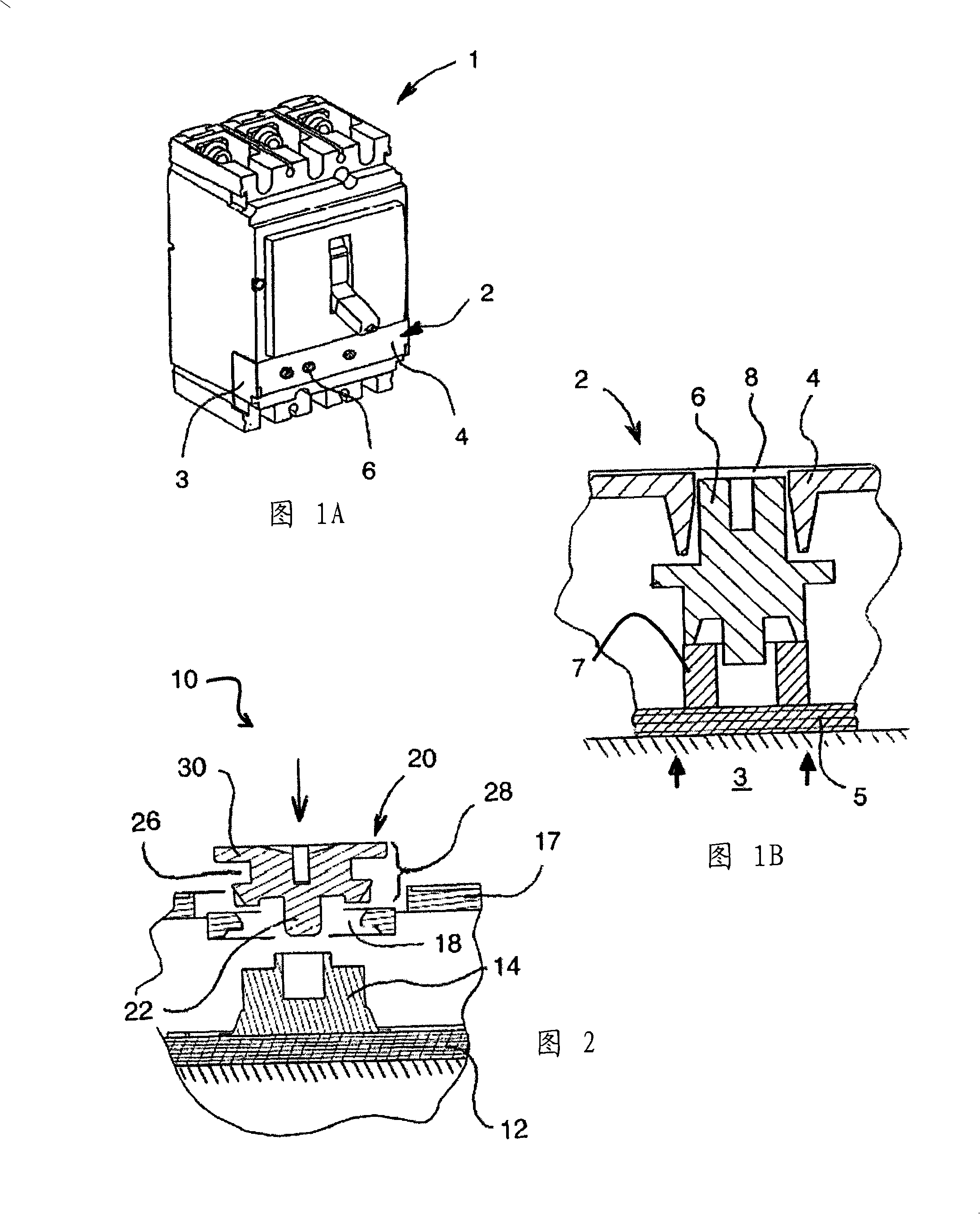

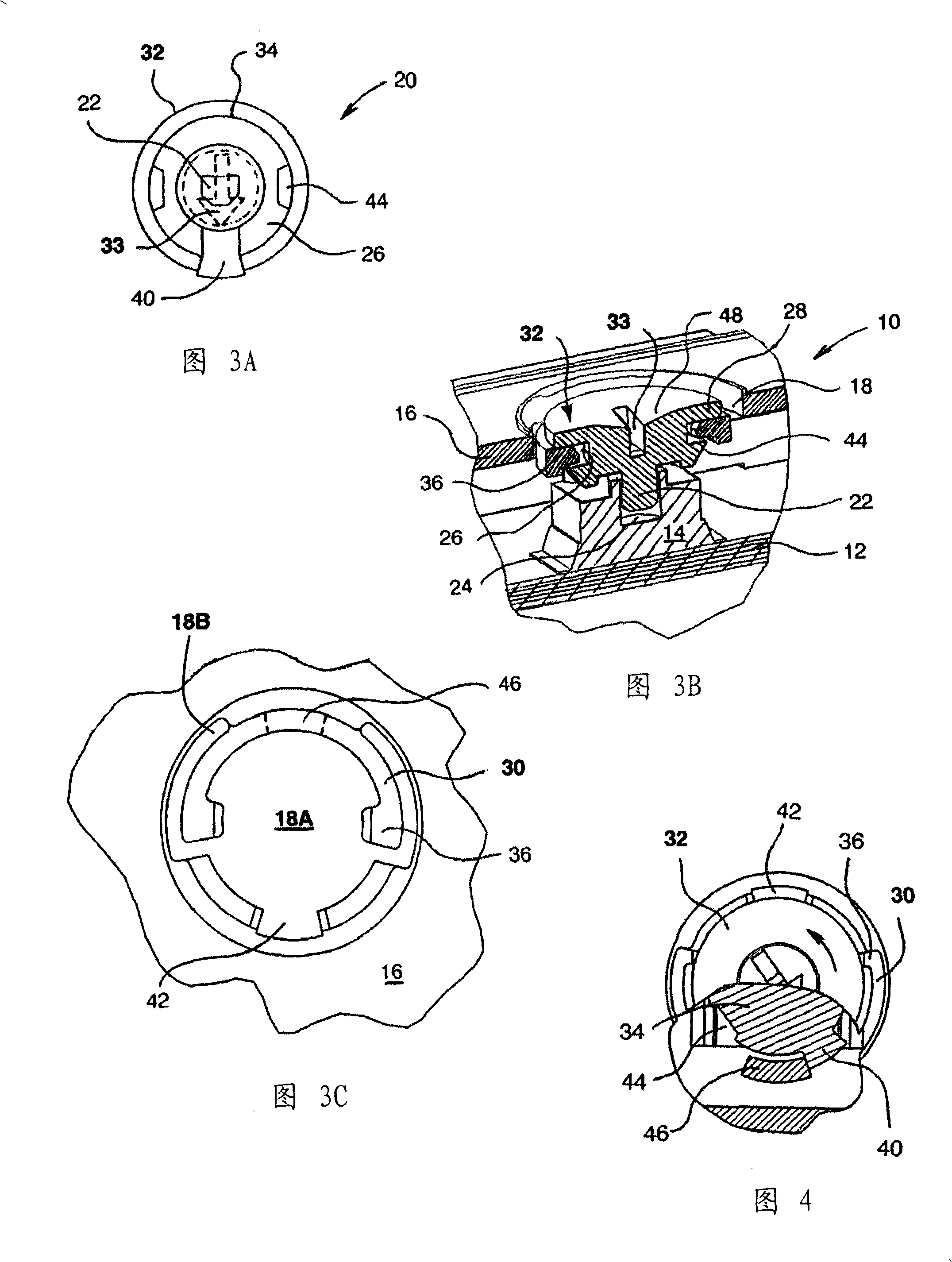

[0023] In the tripping system 10 of the embodiment of the present invention, as shown schematically in FIG. Fix the machine cover 16 in a suitable manner. One face 17 of the cover 16 is substantially parallel to the plate 12, and is provided with a hole 18 aligned with the actuation encoder 14 along the normal of said plate 12, allowing a certain alignment error, which will become more apparent after reading this description. clear. The tripping system 10 can be connected with a circuit breaker, as described with reference to FIG. 1 , and the size of the latter is minimized, especially according to the preferred embodiment, the free distance on the printed circuit board 12 is less than 7mm, and the rotary switch 14 is known at height Orientation takes up two-thirds of that space. The actuating device 20 cannot then take up the natural space, thus limiting the manufacturing options.

[0024] Once the housing of the trip system 10 is obtained, the actuating means 20 , compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com