Manufacturing method of LCD device and TFT completing substrate thereof

A technology of liquid crystal display devices and liquid crystal display panels, which is applied in the manufacture of thin film transistor liquid crystal display devices, and in the field of TFT completed substrates, which can solve problems such as difficult discharge, defective panels, and short circuits in wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for manufacturing a liquid crystal display device, the TFT substrate manufacturing steps comprising:

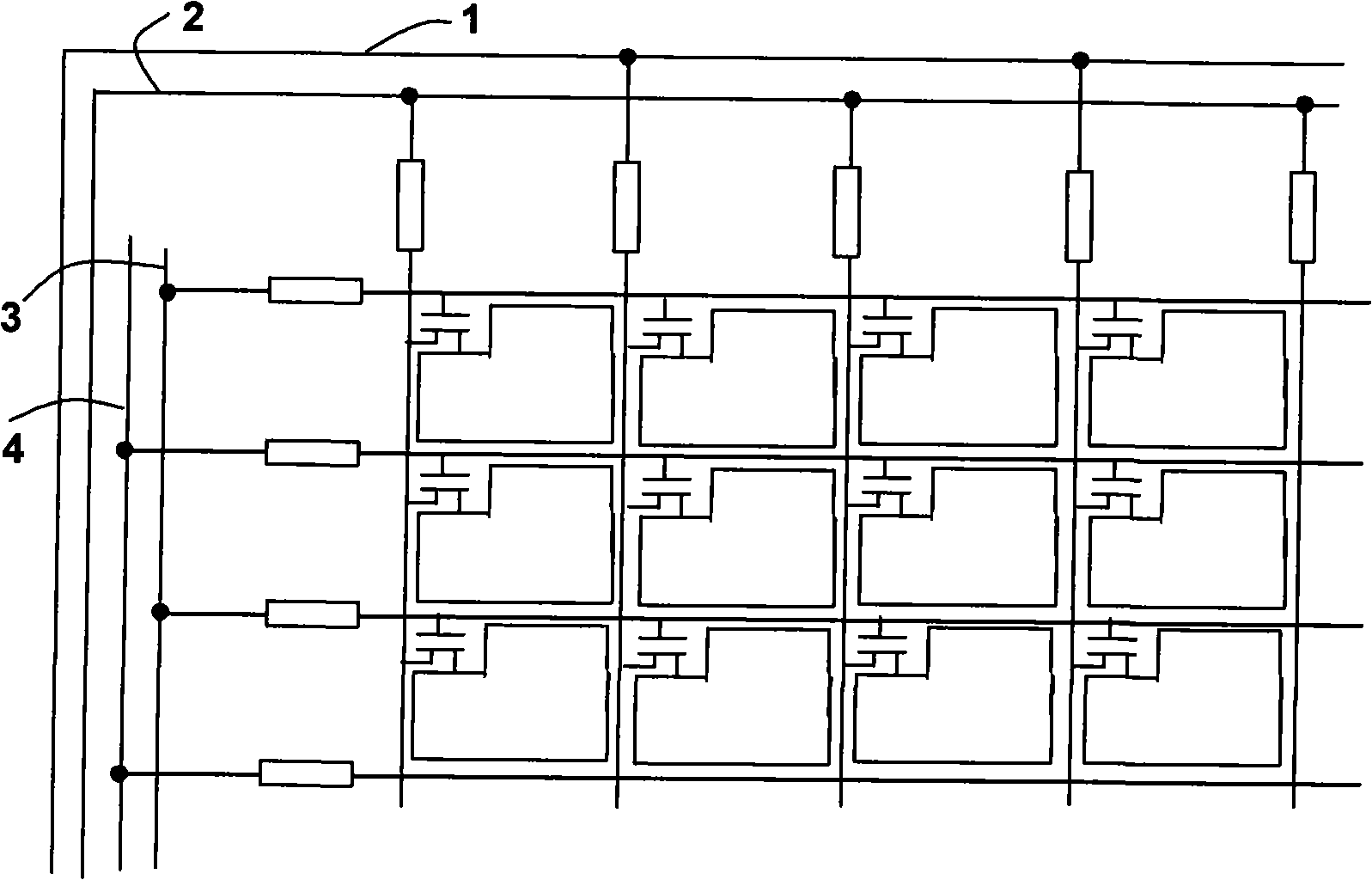

[0071] A glass substrate 37 is provided, provided with a plurality of liquid crystal display panel units and peripheral test circuit areas, a first metal layer 38 is deposited on the glass substrate 37 and a first metal interconnection pattern is etched, the pattern includes The first and second data short-circuit bar wirings 1 and 2 to be connected to the data wiring in the unit extend to the gate wiring in the corresponding peripheral test circuit area,

[0072] An insulating layer 39 and a semiconductor layer 40 are sequentially deposited on the interconnect pattern, and a first photoresist layer 41 is coated,

[0073] The first photoresist layer 41 is subjected to multi-grayscale exposure, so that in the test circuit area, the gate wiring will overlap with the gate shorting bars 3, 4 and the area where the data shorting bars will be electrically connected ...

Embodiment 2

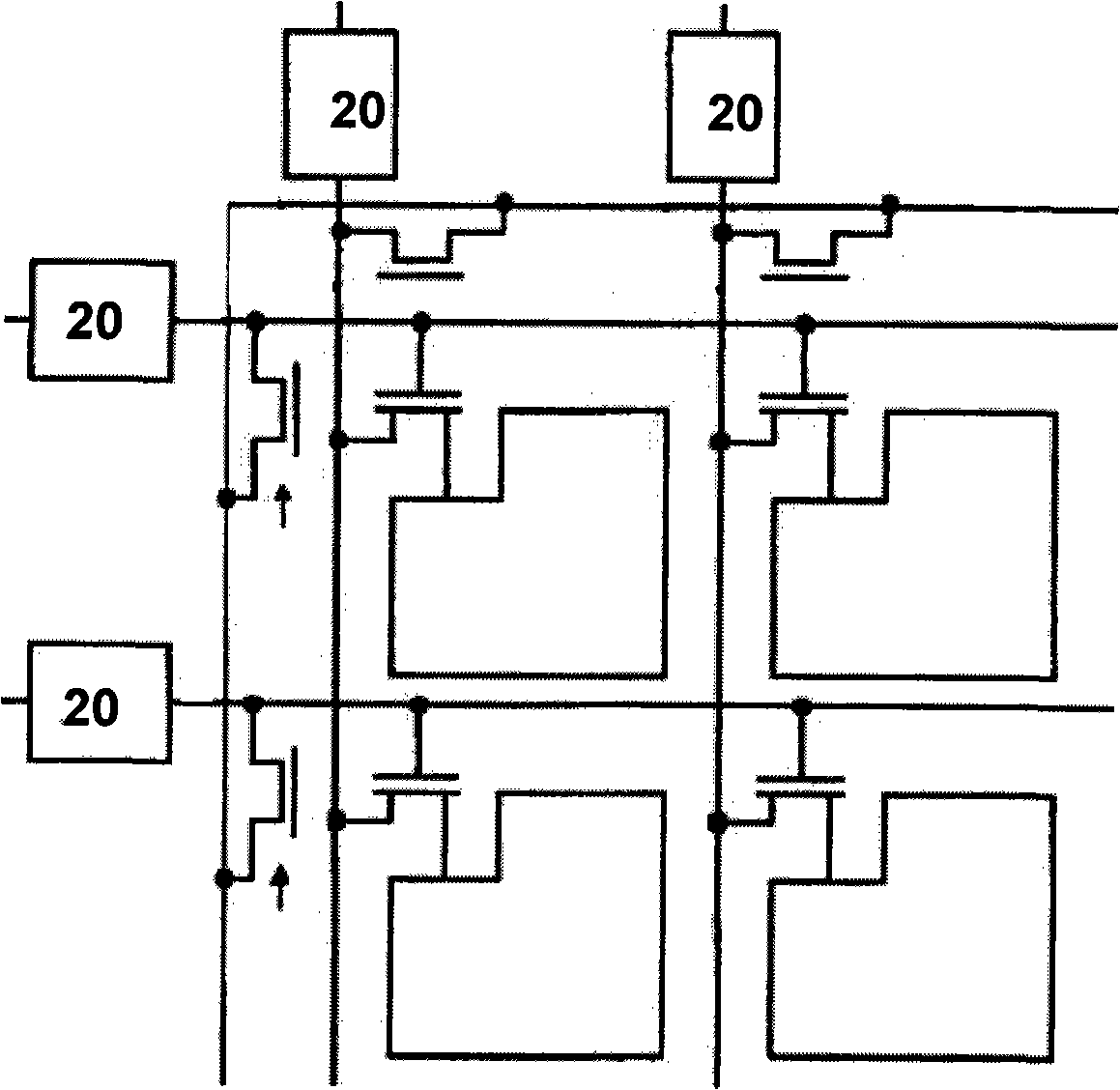

[0083] A manufacturing method of a liquid crystal display device and a TFT completed substrate, the method and structure of which are basically the same as those of Embodiment 1, and electrostatic protection rings 20 are also provided at the terminals of gate wiring and data wiring. Through the conduction effect of the Guard transistors in these electrostatic protection rings 20, the electrostatic protection in the panel after the completion of the entire array process is realized. After the array process is completed and the panel is cut, the electrostatic protection ring 20 in the panel can still be used to protect against static electricity. In order to protect the purpose of static electricity in all process steps.

Embodiment 3

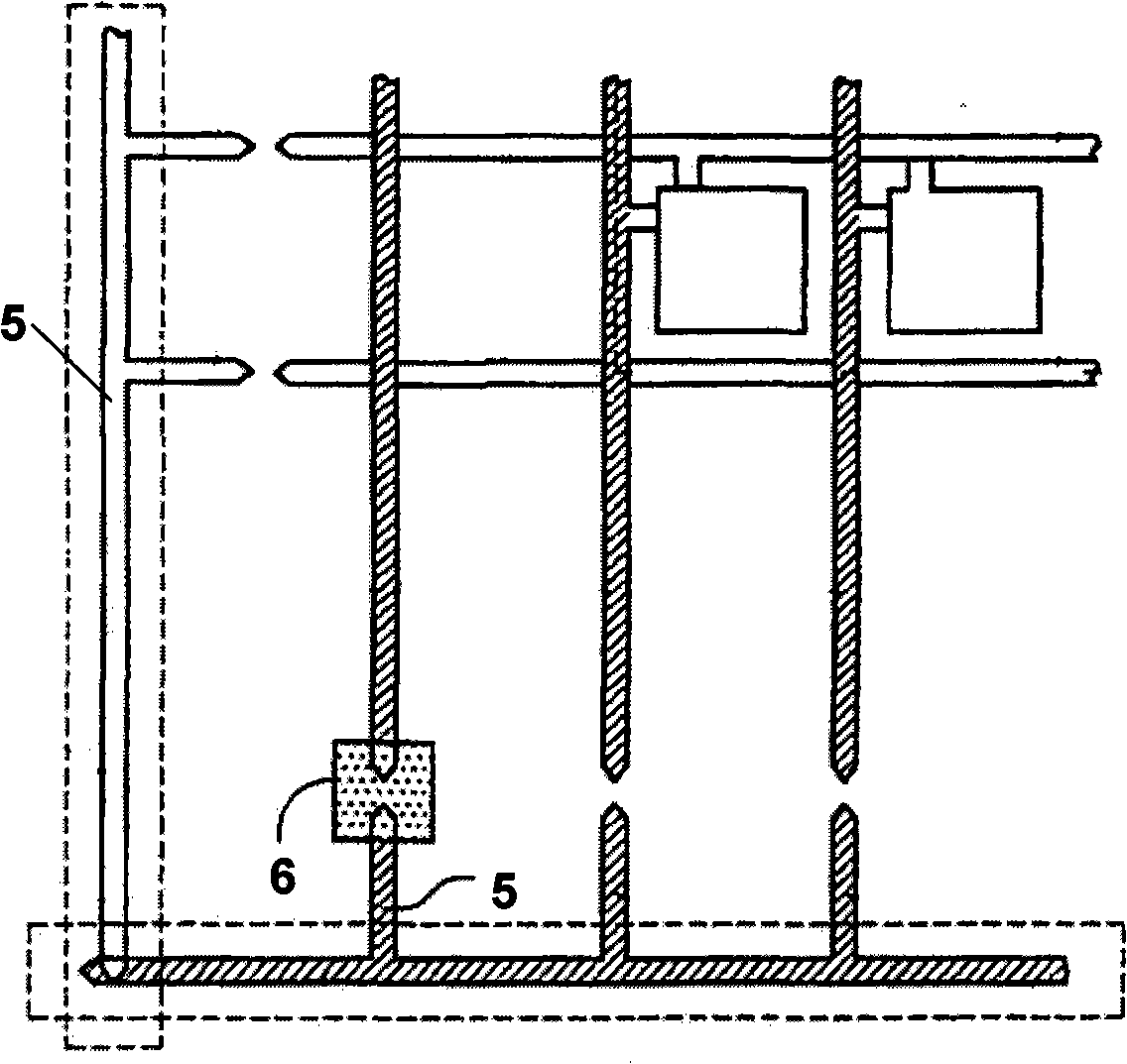

[0085] A manufacturing method of a liquid crystal display device and a TFT completed substrate, the method and structure of which are basically the same as in Embodiment 1, the shorting bar traces 1, 2, 3, and 4 are respectively connected to the array test pads 31 of each panel, and The test terminals of the array test pad groups of different panels on all TFT substrates are connected to each other in order through the auxiliary protective wiring 30 , and connected to the total array test pad group 32 .

[0086] In this way, at the moment when static electricity is generated, the local electrostatic charge can be diffused to the whole large glass substrate to the greatest extent; at the same time, due to the array test structure interconnected between panels, the array test of different products can use the same A set of probes saves the cost of probe development and shortens the product development time to a large extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com