Ultra-short length erbium and ytterbium codoping high gain glass optical fiber superfluorescence light source

A high-gain optical fiber and glass optical fiber technology, applied in the field of super fluorescent light source, can solve the problems of low side pumping efficiency, high requirements for optical path design, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

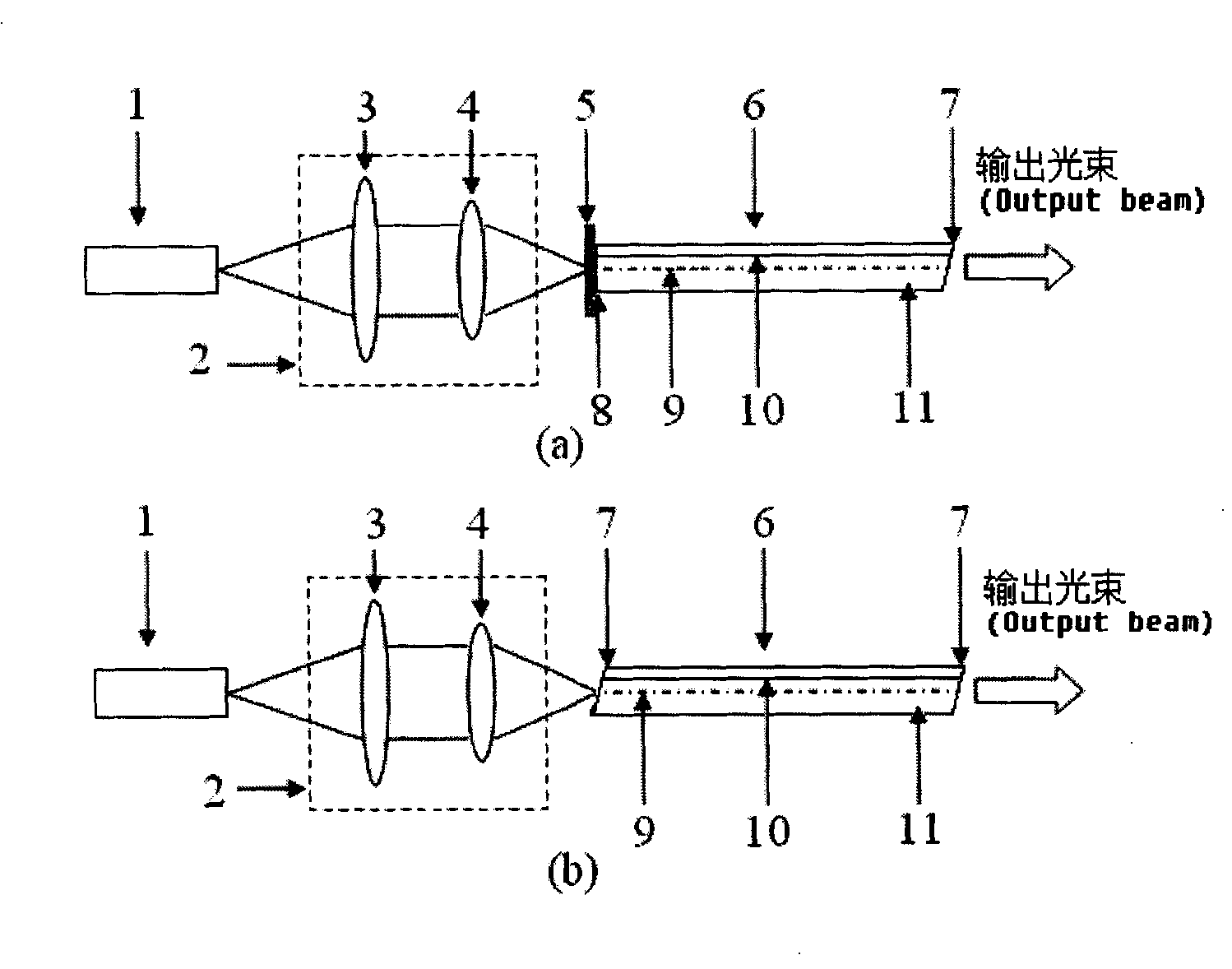

[0085] An ultra-short length erbium-ytterbium co-doped high-gain glass fiber superfluorescent light source, using such as image 3 The structure of (a), including: semiconductor laser (LD) 1, coupling lens system 2, signal light total reflection mirror 5, high-gain optical fiber 6 (pumping light input end is a vertically cut end 8, and the superfluorescent output end is an oblique angle End 7) Four parts. It is characterized by:

[0086] LD1 is Apollo's high-power semiconductor laser (model: S20-976-1) with a maximum output power of 9.20W and a center wavelength of 976nm;

[0087] The coupling lens system 2 is composed of a collimating lens 3 and a focusing lens 4, which can efficiently couple the pump light into the end face of the high-gain optical fiber 6;

[0088] The reflectivity of the signal light total reflection mirror 5 to the light of 1540nm and its vicinity is greater than 99%, and the reflectivity of the light of 976nm and its vicinity is less than 6%;

[0089]...

specific Embodiment 2

[0107] An ultra-short length erbium-ytterbium co-doped high-gain glass fiber superfluorescent light source, using such as image 3 The structure of (a), including: semiconductor laser (LD) 1, coupling lens system 2, signal light total reflection mirror 5, high-gain optical fiber 6 (pumping light input end is a vertically cut end 8, and the superfluorescent output end is an oblique angle End 7) Four parts. It is characterized by:

[0108] LD1 is Apollo's high-power semiconductor laser (model: S20-976-1) with a maximum output power of 9.20W and a center wavelength of 976nm;

[0109] The coupling lens system 2 is composed of a collimating lens 3 and a focusing lens 4, which can efficiently couple the pump light into the end face of the high-gain optical fiber 6;

[0110] The reflectivity of the signal light total reflection mirror 5 to the light of 1540nm and its vicinity is greater than 99%, and the reflectivity of the light of 976nm and its vicinity is less than 6%;

[0111]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com