Method for preparing low-carbon olefins from oxygen-containing compound

A technology for low-carbon olefins and compounds is applied in the field of preparing low-carbon olefins from oxygen-containing compounds, which can solve the problem of low yield of low-carbon olefins, and achieve the effects of improving the total yield and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

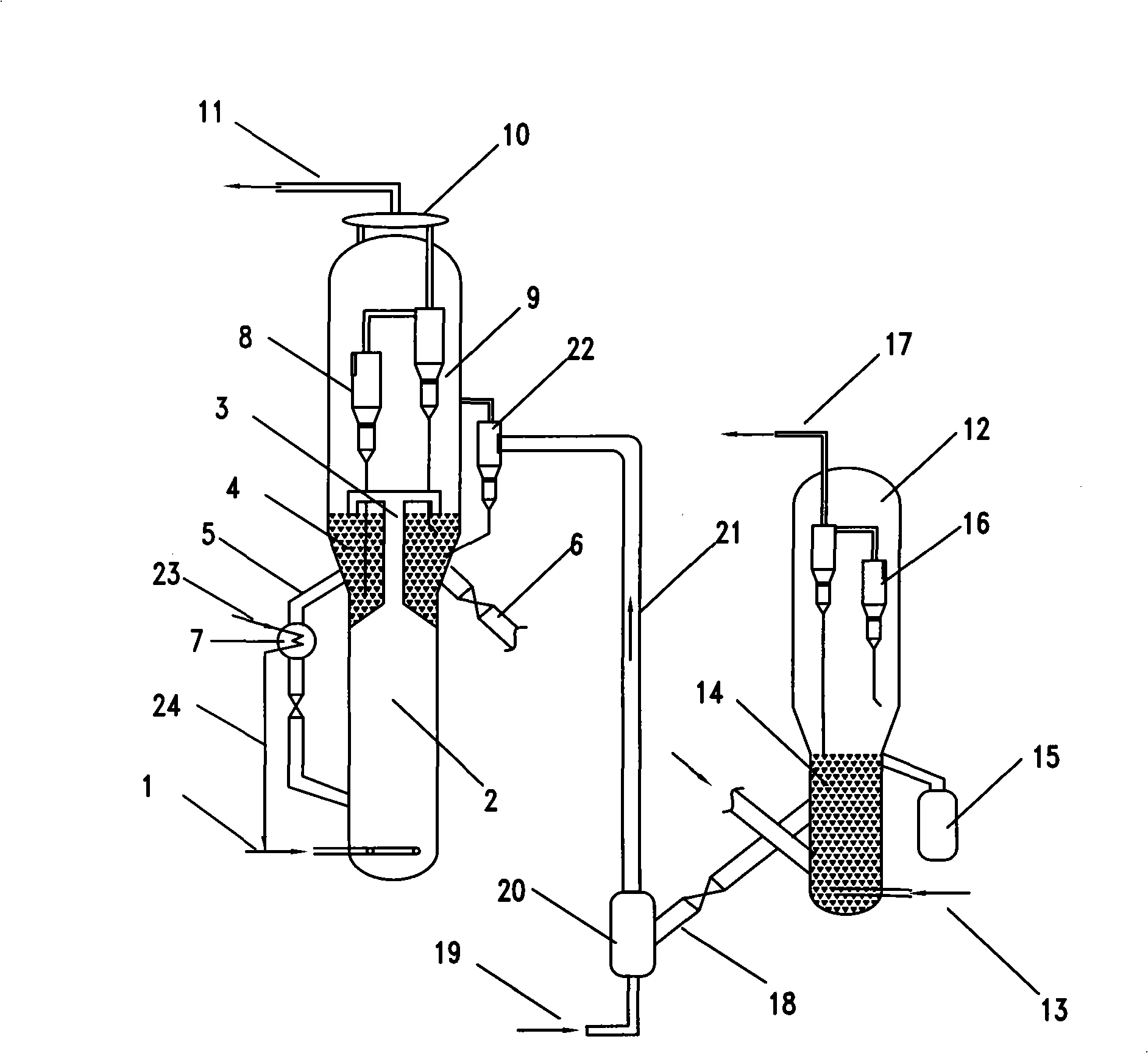

[0020] In the fast fluidized bed reactor, the reaction system is the same as figure 1 . The average temperature of the reaction zone is 500°C, the reaction pressure is 0.1MPa in terms of gauge pressure, pure methanol is fed, and the methanol weight hourly space velocity is 25 hours -1 , the catalyst type is shown in Table 1, the stripping medium in the stripping zone is water vapor, the lifting medium of the regenerated catalyst standpipe is water vapor, the heat exchange medium with the catalyst to be regenerated in the heat exchanger 7 is methanol, the weight of the heat exchange medium and the raw material The flow rate ratio was 0.05:1. The first part of the spent catalyst that enters the regenerator 12 through the catalyst delivery line 6 accounts for 40% by weight of the total spent catalyst, and 100% of the regenerated catalyst enters the catalyst delivery standpipe and contacts with the lifting medium. The average amount of carbon deposited on the catalyst is 2.5% by...

Embodiment 5~6

[0024] According to the conditions described in Example 4, only the reactor temperature was changed, and the experimental results are shown in Table 2.

[0025] Table 2

[0026] parameters

Embodiment 7~8

[0028] According to the conditions described in Example 4, only the type of raw material and the weight hourly space velocity of the raw material were changed, and the experimental results are shown in Table 3.

[0029] table 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com