Manufacturing technology for high-intensity clearance ultra heat resisting aluminum alloy lead and ultra heat resisting aluminum alloy

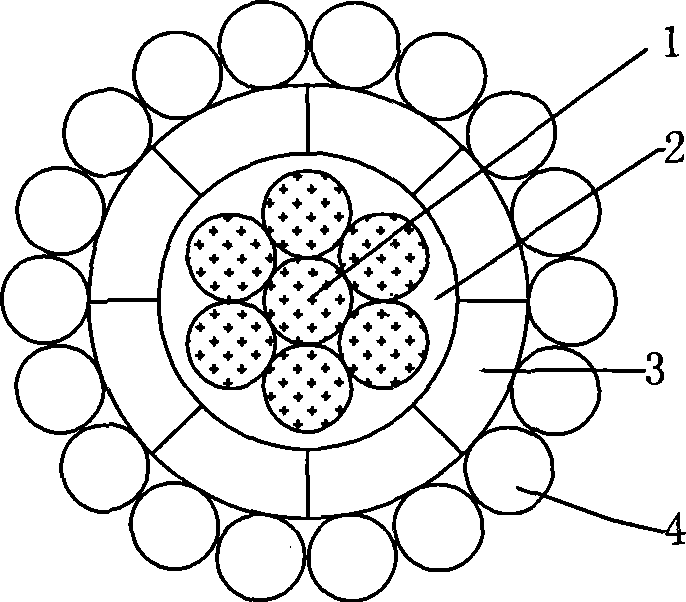

A kind of aluminum alloy wire, manufacturing technology, applied in cable/conductor manufacturing, conductor, insulated conductor and other directions, can solve the problems of small transmission capacity, large coefficient of linear expansion, large sag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

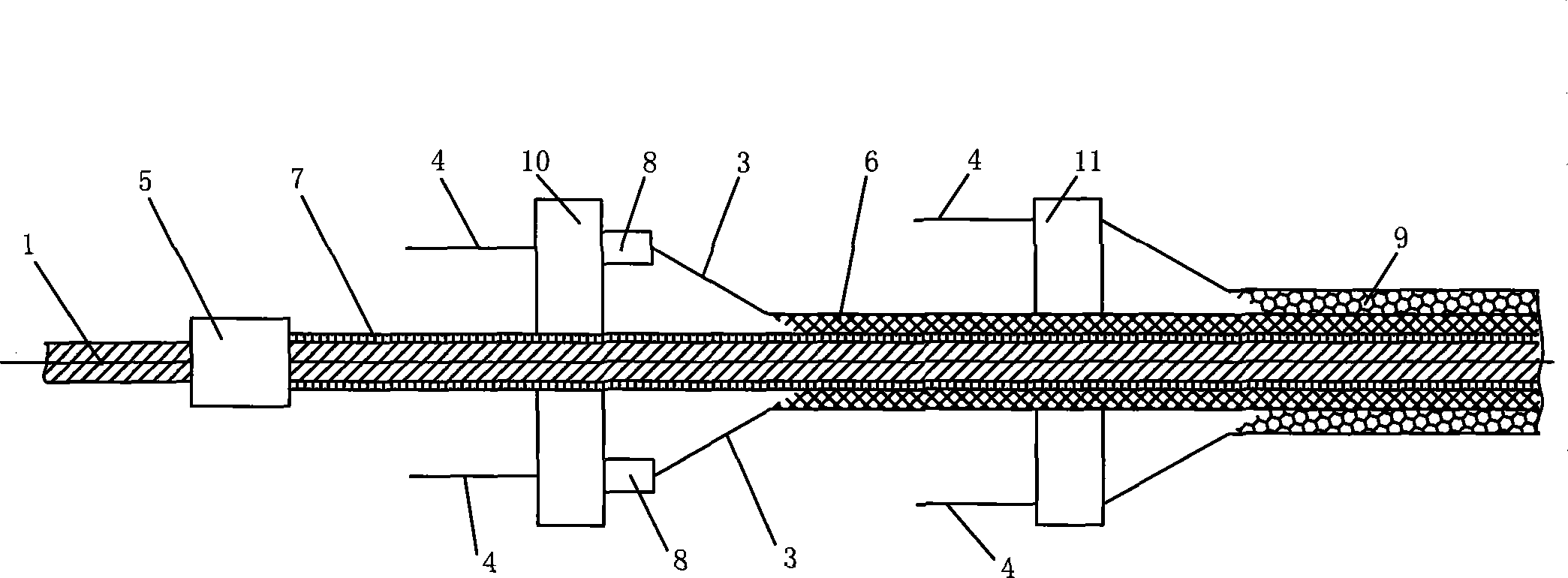

Method used

Image

Examples

Embodiment 1

[0041] The aluminum rod is made of 0.27% (weight) zirconium, 0.18% (weight) iron, 0.11% silicon and traces of manganese, chromium, vanadium, titanium, copper and other elements, and the rest is aluminum, after aging at 400°C for 95h Processed and drawn into a super heat-resistant aluminum alloy round wire, its electrical conductivity is 60.5% IACS, and its tensile strength is 177Kgf / mm 2 , Elongation 2.3%, heat resistance 95%.

Embodiment 2

[0043] The aluminum rod is made of 0.15% (weight) zirconium, 0.10% (weight) iron, 0.05% silicon and traces of manganese, chromium, titanium, copper and other elements, and the rest is aluminum. After aging treatment at 400°C and 95h, Drawn into a super heat-resistant aluminum alloy round wire, its electrical conductivity is 60.8%IACS, and its tensile strength is 171Kgf / mm 2 , Elongation 2.5%, heat resistance 92%.

[0044] Use the super heat-resistant aluminum alloy round wire and the strength is 181kgf / mm 2 Made of high strength galvanized steel wire 400 / 65mm 2 The high-strength gap type super heat-resistant aluminum alloy wire (GZTACSR), which is different from the traditional ordinary 400 / 65mm 2 Table 1 shows the comparison of technical performance parameters of aluminum steel-reinforced wire (ACSR).

[0045]

[0046] Note 1): Calculation conditions for sag: laying span 300m, tight line temperature 15°C;

[0047] It can be seen from the above table that compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com