Double reaction area integral waste gases biodecontamination reactor and waste gas treatment method thereby

A dual-reaction zone, biological purification technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as reducing the footprint of the reactor, and achieve compact structure, no secondary pollution, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

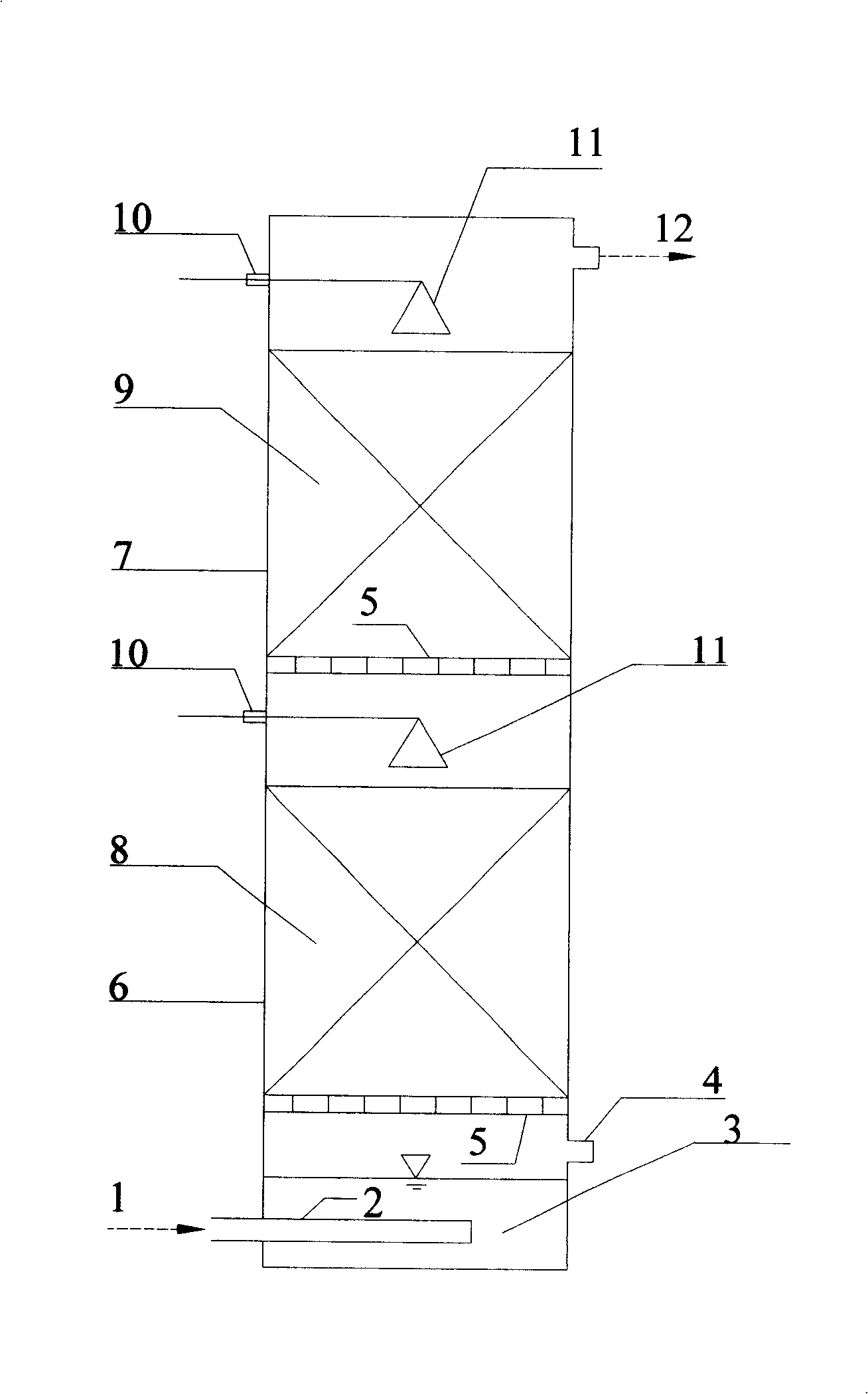

[0037]See figure 1 . The dual-reaction zone integrated exhaust gas biological purification reactor made of plexiglass has a basic structure of a cylinder with a diameter of 90mm and a total volume of 5L. It is divided upwards by two gas distribution plates 5 into gas humidification zones 3, Three parts of the first bioreaction zone 6 and the second bioreaction zone 7;

[0038] An air inlet 1 is opened on the side wall of the lower part of the gas humidification area, a perforated pipe 2 is installed at the air inlet, and a drain port 4 is opened on the side wall of the upper part of the gas humidification area;

[0039] In the first biological reaction zone, acid-resistant inert first biological reaction zone packing 8 is housed, and a spray liquid inlet 10 is arranged on the side wall of the first biological reaction zone, and a connection nozzle 11 is installed at the spray liquid inlet. Pipeline, the nozzle is above the filler in the first biological reaction zone; the r...

Embodiment 2

[0045] The reactor is as in Example 1.

[0046] High-concentration exhaust gas enters the gas humidification zone 3 from the air inlet 1 at the lower part of the gas humidification zone 3 through the gas perforated tube 2. At this time, the liquid level in the humidified zone is higher than the height of the gas perforated tube 2, and the gas goes up after being humidified in the liquid phase Flow, enter the first biological reaction zone 6 through the first gas distribution plate 5, the first biological reaction zone operates at an acidic pH, the nozzle 11 regularly sprays the acidic nutrient solution through the pipeline, most of the waste gas produces acid, hydrophobic Reactive gas pollutants are degraded by acidophilic bacteria and fungi on the porous media packing (such as sponge, polypropylene pellets or ceramics, etc.) in the first biological reaction zone, and the gas load is greatly reduced; undegraded low-concentration pollutants and metabolic intermediates The produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com