Electric iron

An electric soldering iron and soldering iron tip technology, which is applied to soldering irons, electric heating devices, metal processing equipment, etc., can solve the problems of high replacement cost and large temperature error of soldering iron tips, and achieve the purpose of avoiding accelerated aging, improving quality performance and enhancing monitoring capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

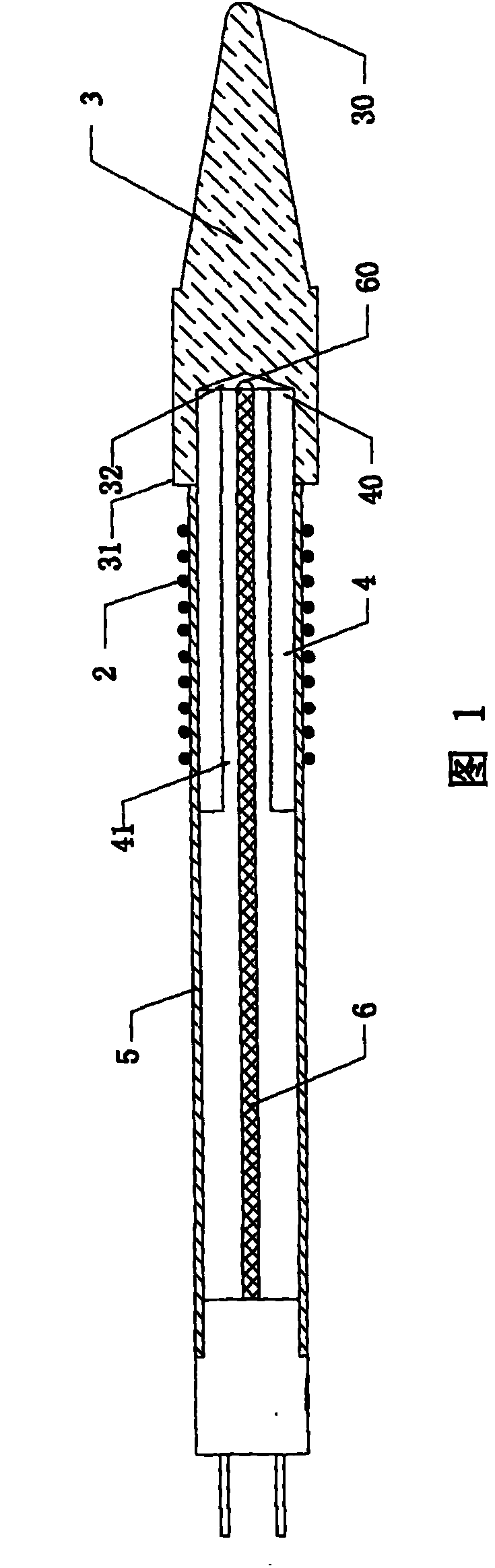

[0017] As shown in FIG. 1 , the present invention provides an electric soldering iron, which includes a soldering iron tip 3 , an eddy current heating core and a thermocouple 6 for sensing the temperature of the soldering iron tip.

[0018] Wherein, the rear end 31 of the soldering iron tip 3 is provided with a blind hole 32 .

[0019] The eddy current heating core includes an iron pipe body 5 generating eddy current and a coil 2 wound on the iron pipe body 5 . The iron pipe body 5 preferably adopts a pure iron pipe, and may also adopt a pipe body coated with a layer of iron on the surface. The iron pipe body 5 is provided with a heat pipe 4 that conducts heat to the tip of the soldering iron. The outer wall of the heat pipe 4 is in close contact with the iron pipe body 5, or a layer of iron is directly plated on the heat pipe 4 as the iron pipe body. 5. The heat pipe 4 is provided with a lumen 41 for the thermocouple 6 to pass through. The heat pipe 4 is preferably made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com