Inner vibration sequence injection molding die device and injection molding technique thereof

A sequential injection molding and mold technology, applied in the field of internal vibration sequential injection mold device and its injection molding process, can solve the problems of complex polymer molding, weld lines, stagnation, etc., to reduce product defects, eliminate weld lines and bubbles, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

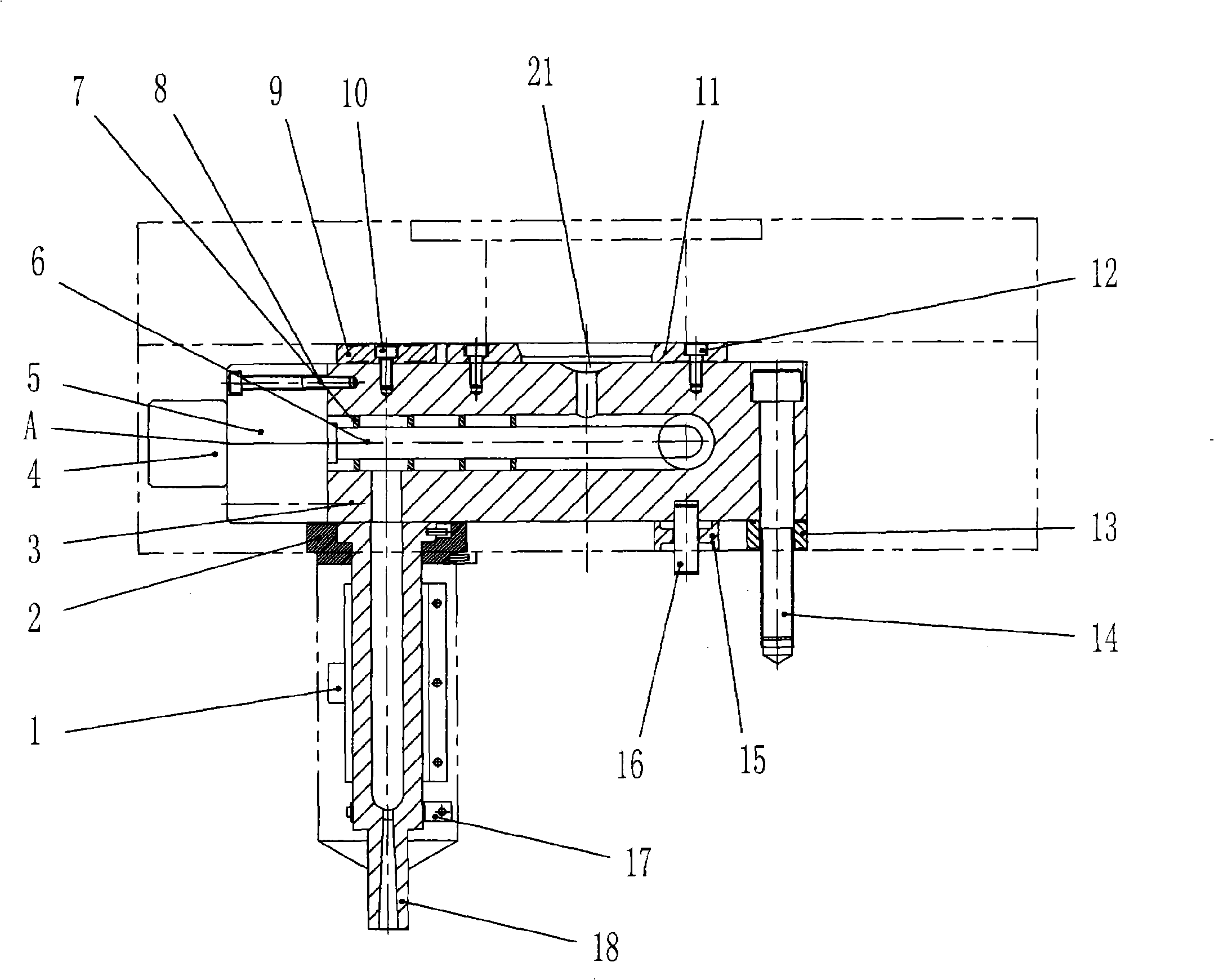

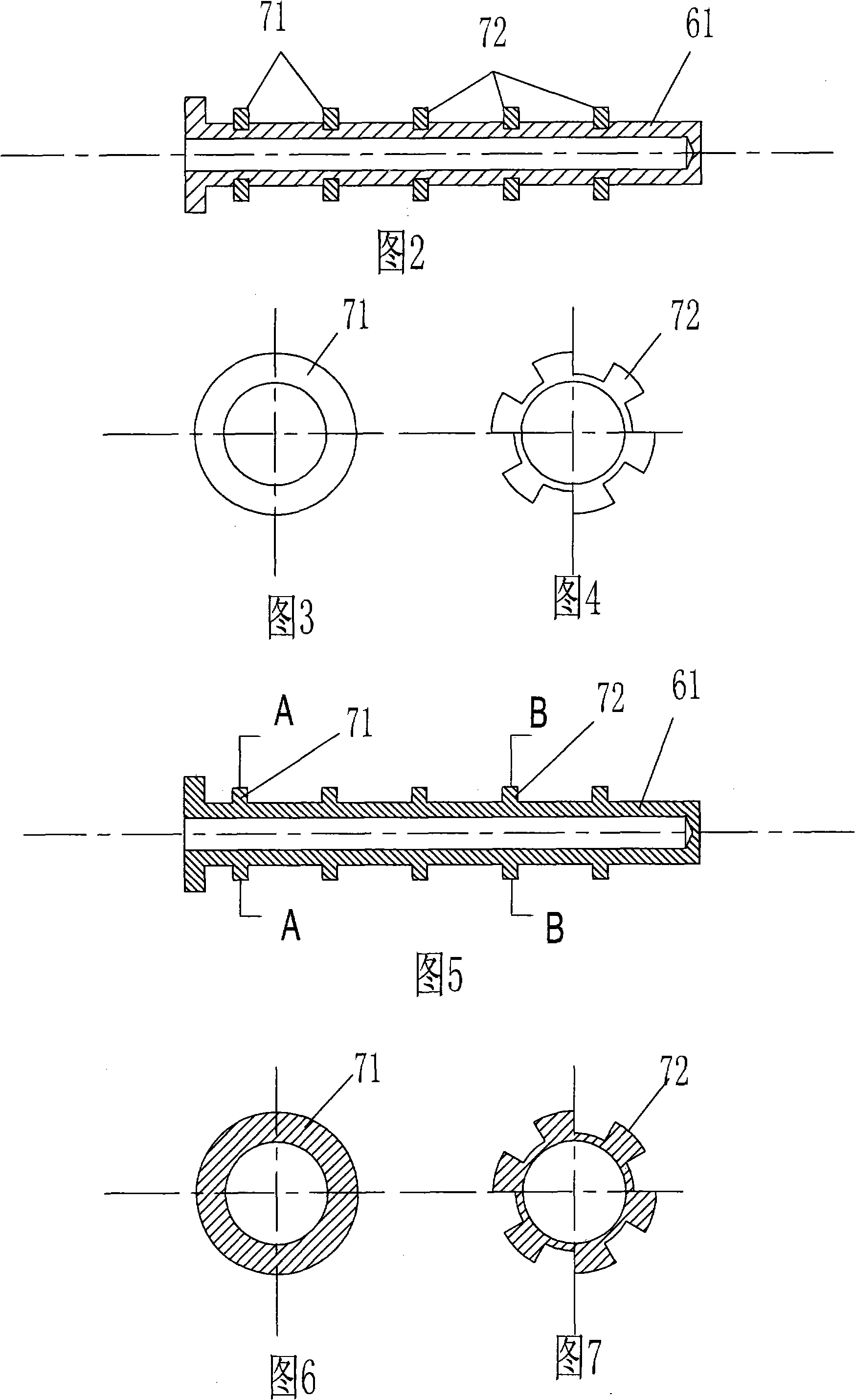

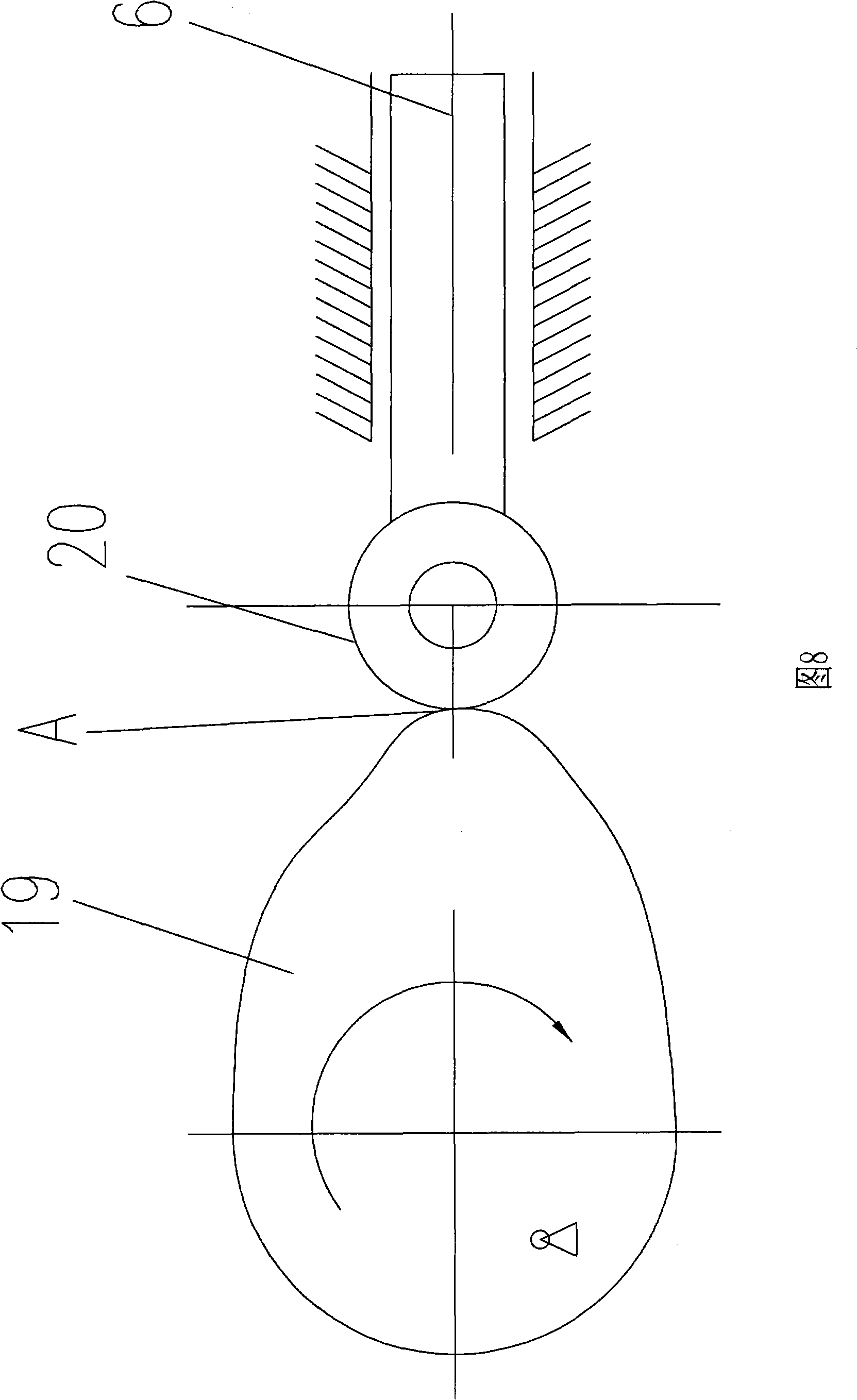

[0035] The structural representation of the vibration sequence injection mold device in the present invention is as follows: figure 1 As shown, it includes a heating body 6 placed inside the hot runner plate 3 and a heating ring 1 placed outside the hot runner plate 3. The heating ring 1 is connected to the heating body 6 through the hot nozzle 18 and the hot nozzle pad cover 2, wherein the heating The body 6 is also provided with a reciprocating linear motion mechanism A, and the outside of the heating body 6 is provided with a spacer 7 which moves together with it.

[0036] The above-mentioned reciprocating linear motion mechanism A includes an electromagnetic block 4 and a stopper 5. The electromagnetic block 4 is connected to the heating body 6 through the stopper 5 and the connector 8. The electromagnetic block 4 is placed beside the electromagnet that controls its attraction. The outer side of the heating coil 1 is provided with a temperature sensing coil 17 .

[0037] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap