Technique for synthesizing 4A zeolite for detergent by using economic aluminum source

A synthetic detergent and economical technology, applied in the directions of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems of increased b value of zeolite products, difficult to remove, process waste, etc., and achieve economic benefits Significant social benefits, reducing waste liquid efflux, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

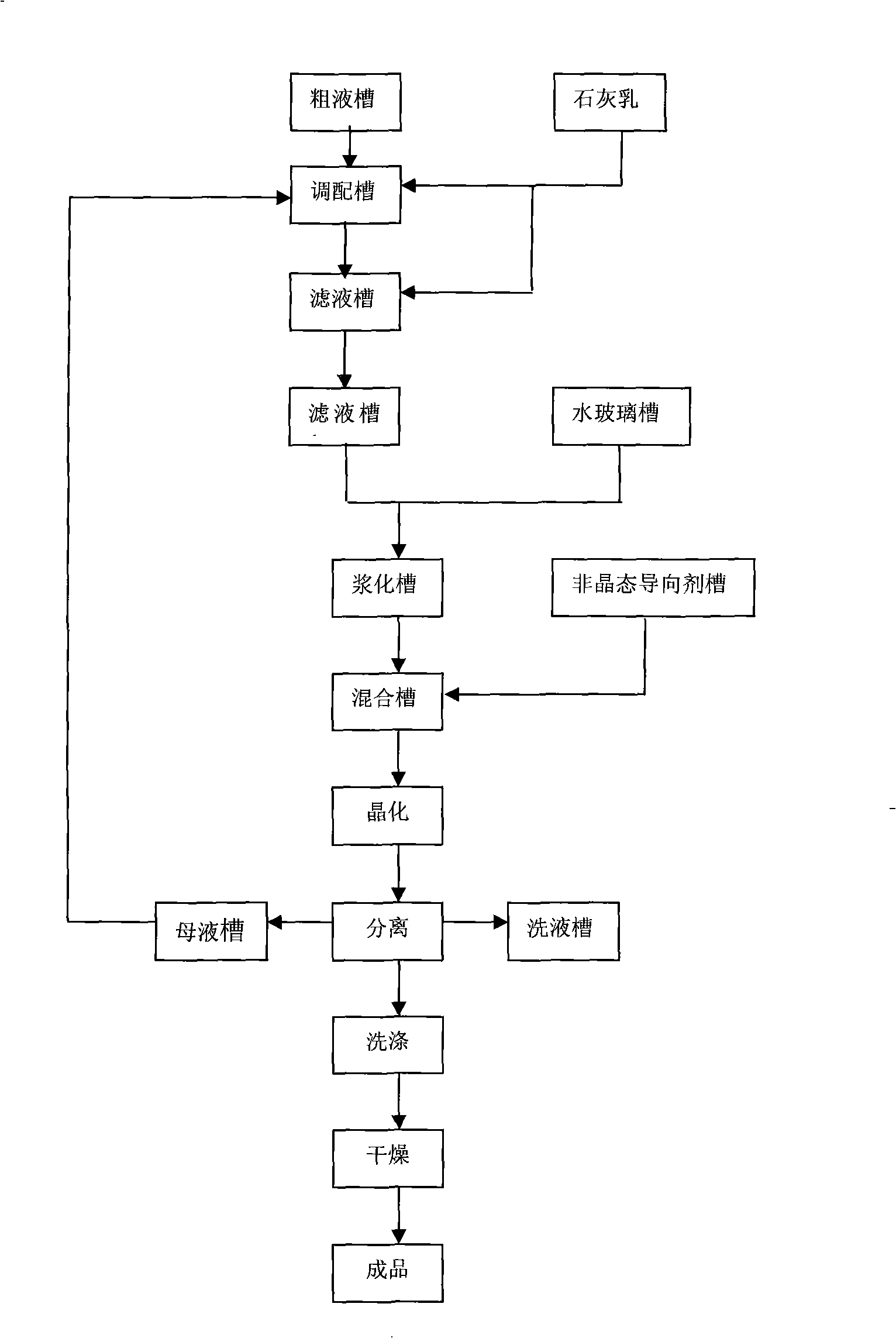

Method used

Image

Examples

Embodiment 1

[0018] Solution A:

[0019] Take the sodium aluminate solution that has not been desiliconized in the alumina production process, and use 4A zeolite mother liquor to prepare it into Al 2 o 3 The content is 65g / L. Add milk of lime with a total amount of 1.0‰ and 3.0‰ (the volume percentage of the sodium aluminate solution that has not been desiliconized after the preparation, the same below) in two separate additions to the qualified solution, and the amount added each time It is 50% of the total volume, that is, after the prepared sodium aluminate solution is qualified, add 50% milk of lime, filter, add the remaining 50% milk of lime to the filtrate, and filter again. The temperature of the filtrate was controlled at 65°C and was ready for use.

[0020] Solution B:

[0021] Prepare industrial raw water glass (M=2.0-3.1), and control the temperature at 45° C. for use.

[0022] The above two solutions were injected into the synthesis reactor synchronously through two meteri...

Embodiment 2

[0029] Except that the way of adding the amorphous directing agent is different from that in Example 1, the rest of the steps and experimental conditions are the same as in Example 1. The amount of amorphous directing agent added is 3‰ of dry basis zeolite weight, and 0.56m 3 The flow rate of / h is injected into the crystallization reactor synchronously with the synthesized gel, and then the crystallization is carried out by raising the temperature.

[0030] The experimental results are listed in the table below.

[0031] Total amount of milk of lime added Calcium exchange D50

[0032] Sample number b value Crystallinity (%)

[0033] (‰) (mgCaCO 3 / g-Z) (μm)

[0034] Sample 11.0 310 2.43 0.51 86.5

[0035] Sample 23.0 311 2.40 0.42 87.2

[0036] SME pictures of obtained 4A zeolite products are shown in figure 2 .

Embodiment 3

[0038] The 4A zeolite process for synthesizing detergents using economical aluminum sources of the present invention adopts the sodium aluminate solution that has not removed silicon in the alumina production process and the 4A zeolite for industrial water glass synthesizing detergents, wherein:

[0039] The sodium aluminate solution that has not been desiliconized is prepared with the mother liquor produced in the production of zeolite, so that after the preparation, the Al 2 o 3 The content is 80g / L. Add 4‰ of the sodium aluminate solution volume of lime milk to the sodium aluminate solution after preparation. The solid content is 200g / L. The lime milk is added in two times. The first time is to use the zeolite mother liquor to prepare Qualified solution is added, which is 50% of the total volume of milk of lime, and the second time is added to the filtrate after filtration, and then filtered.

[0040]The amorphous directing agent is added in a continuous way, and the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com