Method for removing ammonia nitrogen in sludge landfill percolate by utilizing natural zeolite

A natural zeolite and landfill technology, applied in the field of environmental engineering, can solve the problems of reduced efficiency, increased infrastructure investment and operating electricity costs, increased biological aerobic oxidation time, etc., to achieve low cost, small impact, and good ammonia nitrogen removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for utilizing natural zeolite to remove ammonia nitrogen in sludge landfill leachate, comprising the steps of:

[0025] Add clinoptilolite with a particle size of 0.45 mm to 0.90 mm into the leachate of the sludge landfill, and stir for 2.5 hours.

[0026] Leachate collection method of sludge landfill:

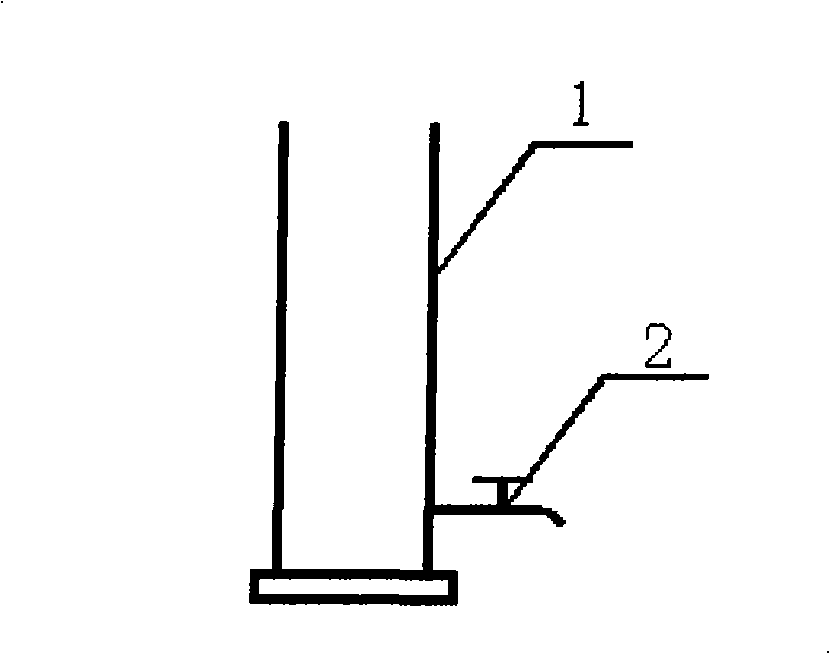

[0027] The sludge is taken from dewatered sludge of a sewage treatment plant in Tianjin, with a moisture content of 70%-80%. Put the sludge into the leachate collection device of the sludge landfill site - the FRP simulated landfill column, the inner diameter of the column is 600mm, the column height is 1800mm, the top is reserved for the sampling port, and the bottom is reserved for the sampling port, and the sampling port is 200mm away from the bottom of the column ,See figure 1 (1 in the figure is the column body of the FRP simulated landfill column, and 2 is the leachate sampling pipe). Fill the bottom of the simulated landfill column with stones 0.15m h...

Embodiment 2

[0031] A method for utilizing natural zeolite to remove ammonia nitrogen in sludge landfill leachate, comprising the steps of:

[0032] Add clinoptilolite with a particle size of 0.45 mm to 0.90 mm into the leachate of the sludge landfill, and stir for 2 hours.

Embodiment 3

[0034] A method for utilizing natural zeolite to remove ammonia nitrogen in sludge landfill leachate, comprising the steps of:

[0035] Add clinoptilolite with a particle size of 0.45 mm to 0.90 mm to the leachate of the sludge landfill, and stir for 4.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com