Composite heat treatment method for 30CrMnSiA steel thin wall spinning cylinder-shape element

A composite heat treatment and thin-walled technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., to achieve the effect of improving tissue stability and machinability, and solving high processing accuracy and hydraulic strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

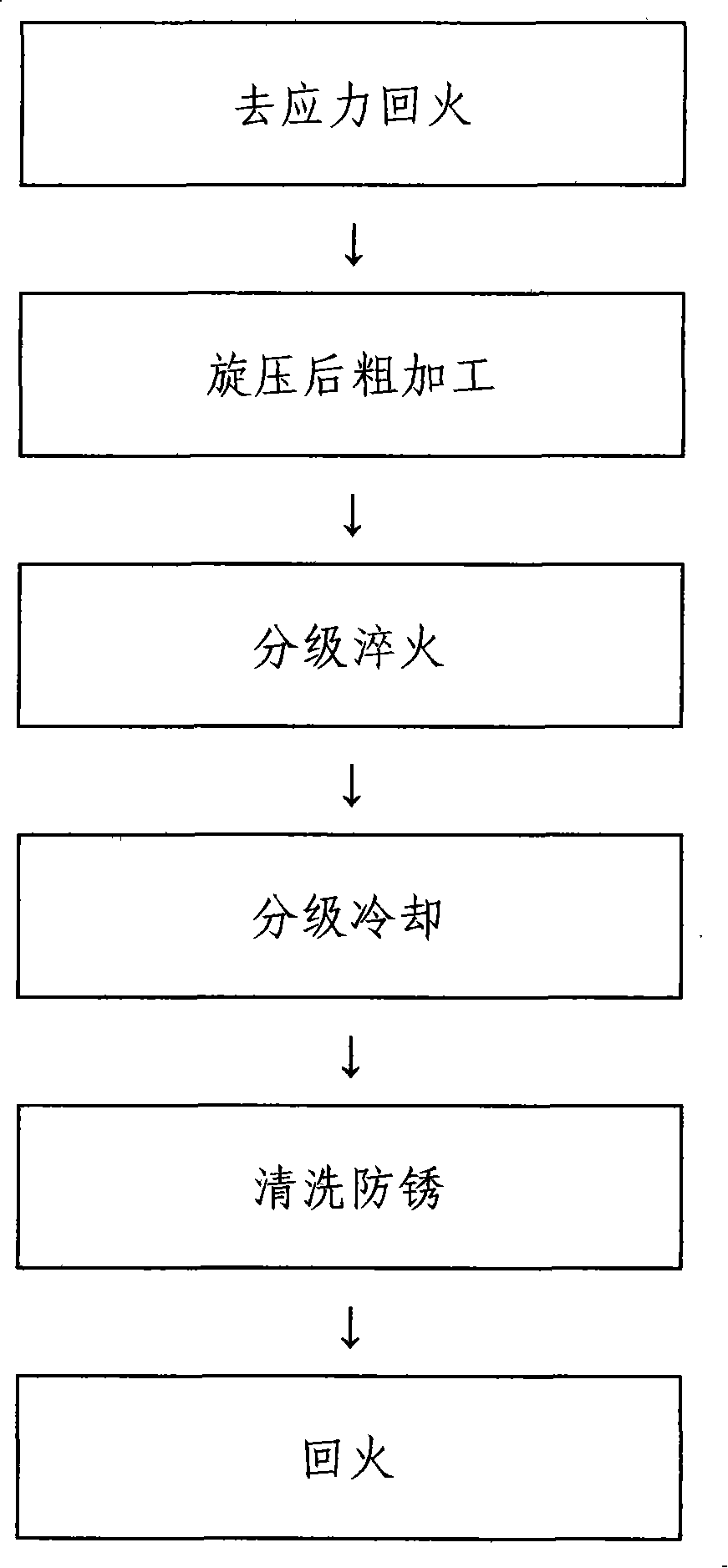

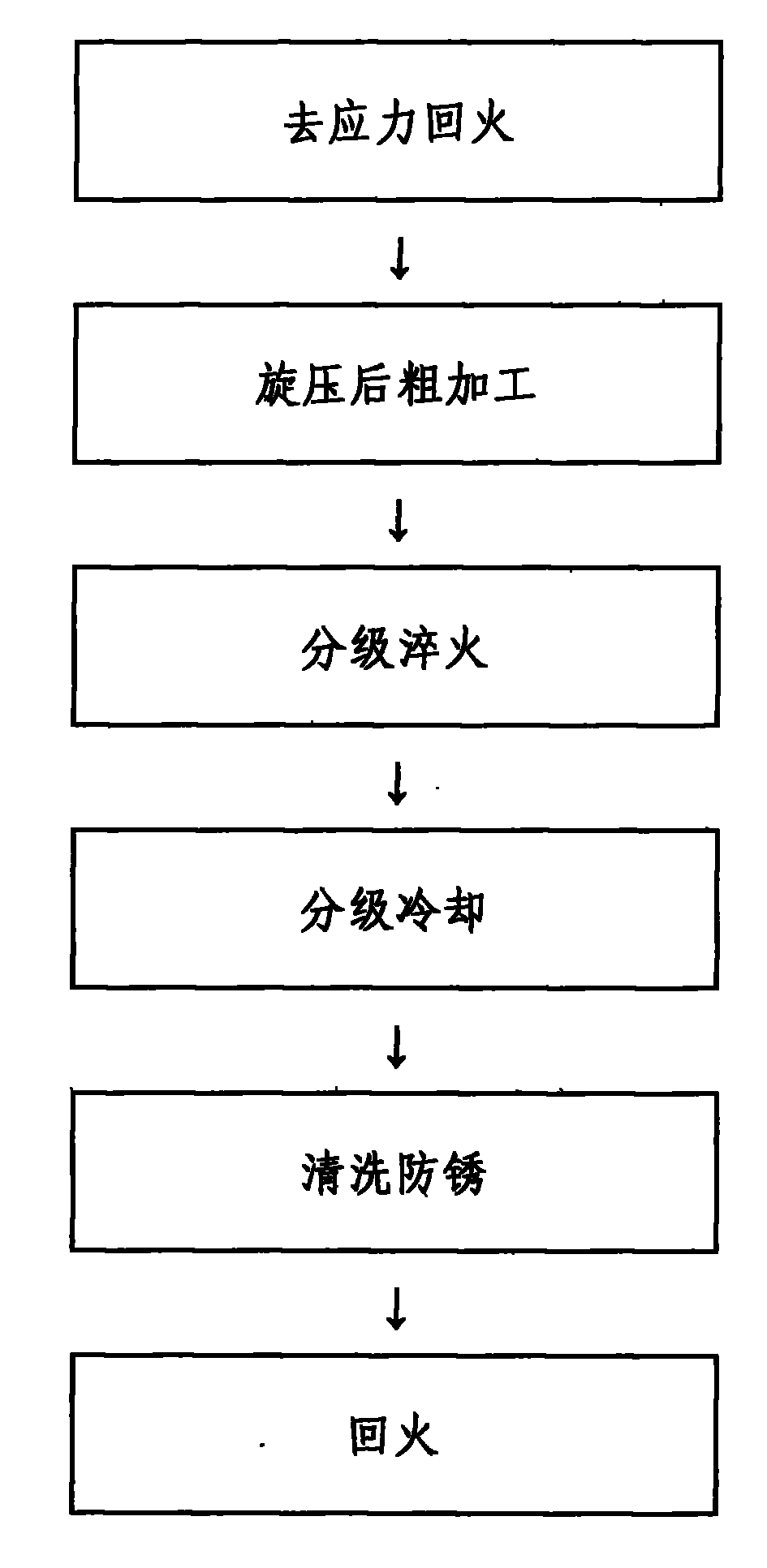

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] Referring to the accompanying drawings, after spinning 30CrMnSiA steel, inspect the size of the formed workpiece and whether there are cracks, etc., and carry out appropriate stress relief and tempering for the qualified workpiece (temperature 400-480°C, time 120-360 minutes) , so that the residual stress generated by the workpiece through spinning can be released to a certain extent, rough machining the workpiece after stress relief and tempering, and quenching the workpiece in stages (preheating 200-500°C, heating in a salt bath furnace 870-910°C) , and then carry out graded cooling on the workpiece (nitrate salt isothermal tank or alkali bath isothermal tank is cooled to 180-280 ° C, air-cooled to below 50 ° C), after the workpiece is cooled, wash off the residual salt or lye attached to the surface of the workpiece , and carry out passivation and anti-rust treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com