Process for producing nano-crystalline platinum carbon catalyst

A platinum-carbon catalyst and nanocrystal technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of difficult preparation of highly active and highly dispersed nanocrystalline platinum-carbon catalysts, platinum particle size and Dispersion is difficult to control effectively, poor stability and reproducibility, etc., to achieve the effect of easy control, high application times, and narrow particle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

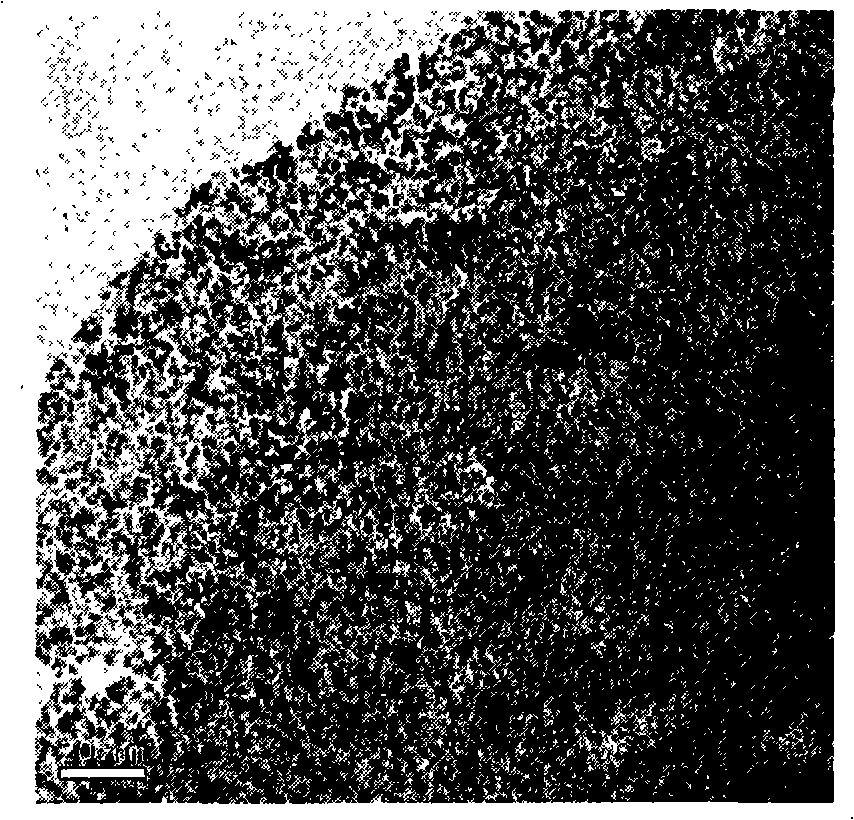

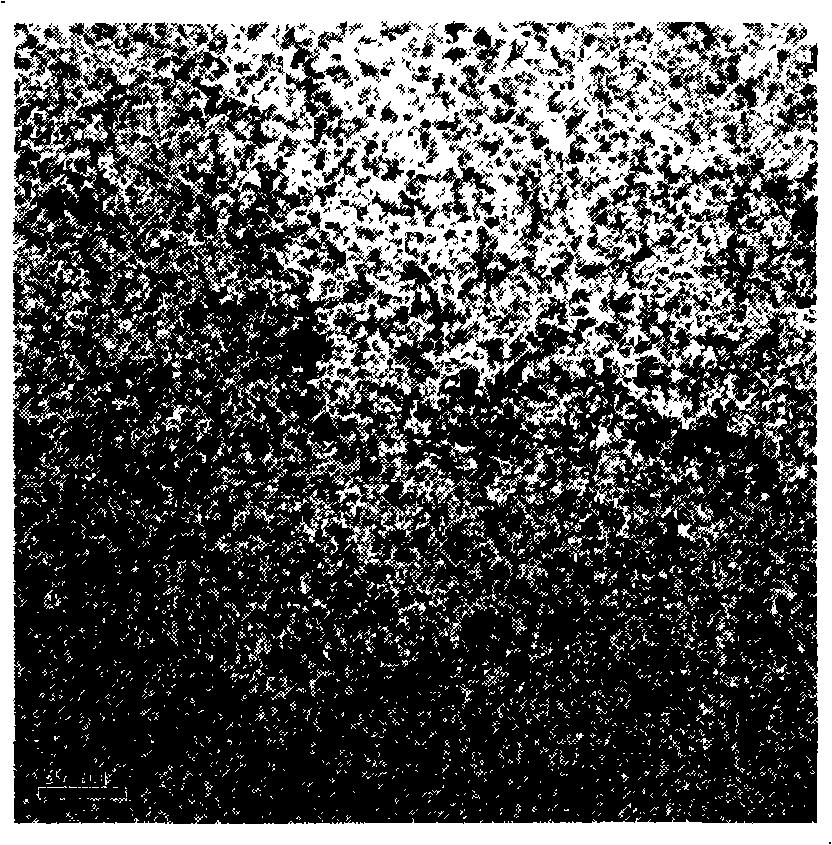

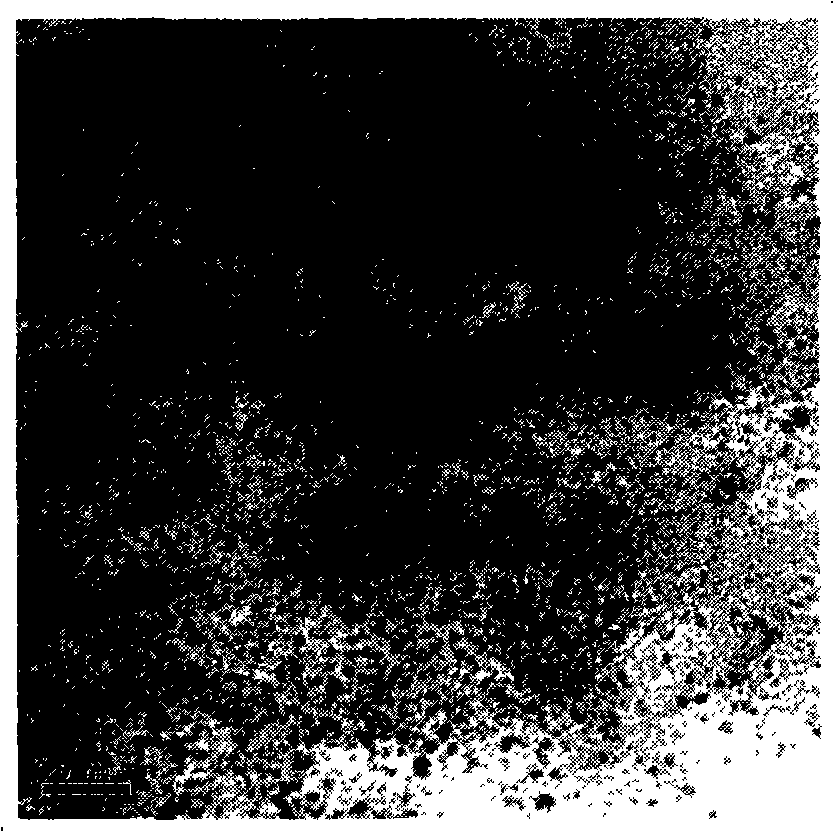

Image

Examples

Embodiment Construction

[0061] A preparation method of highly active nanocrystalline platinum carbon catalyst is characterized in that: it is carried out according to the following steps:

[0062] 1. Preparation of Platinum Complexes

[0063] Dissolving platinum tetrachloride PtCl with mixed solvent of ketone and alcohol 4 After powdering, under the temperature condition of 20-55℃, use ultrasonic treatment for 20-90min, in which:

[0064] The above ultrasonic energy is controlled at 1-10W / cm 2 between,

[0065] The above-mentioned ketone-alcohol mixed solvent is a ketone-alcohol mixture prepared from an alcohol solvent and a ketone solvent in a ratio of 1:1, wherein the alcohol solvent is one or more components of ketone, ethyl ketone, and acetone in any volume ratio The solvent prepared; the ketone solvent is a solvent prepared by one or more components in methanol, propylene glycol, polyvinyl alcohol, and ethylene glycol in any volume ratio.

[0066] Mixed solvent of ketone alcohol and platinum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com