Ceramic trunk piston for medical equipment and preparation method thereof

A ceramic plunger and medical equipment technology, applied in the field of high-quality ceramic plunger, can solve the problems of affecting equipment use efficiency, short service life, poor wear resistance, etc., and achieve high strength, long service life and low pore concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

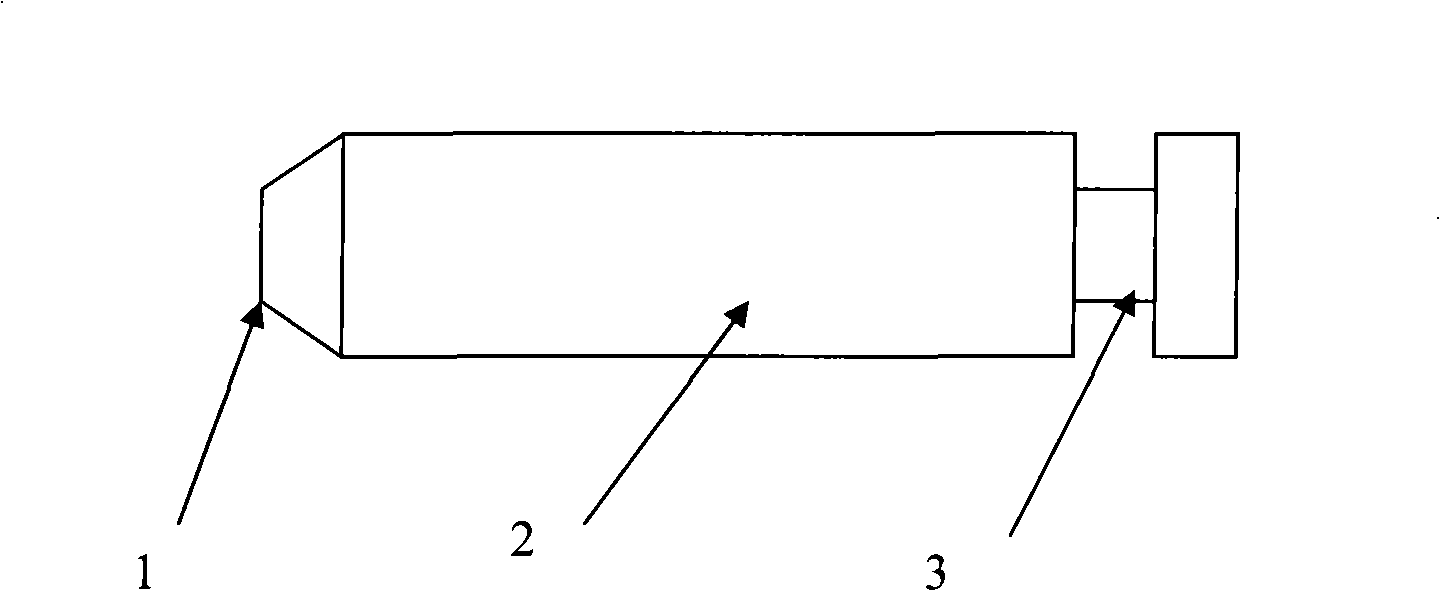

Image

Examples

example 1

[0027] Example 1. The ceramic plunger for medical equipment is completed by the following raw materials and steps:

[0028] raw material selection

[0029] (1) According to the following formula ingredients

[0030] AL 2 o 3 99.2%

[0031] Y 2 o 3 +CeO 2 +Nb 2 o 5 0.5%

[0032] MgO 0.3%

[0033] Proceed as follows

[0034] (2) Adopt conventional chemical co-precipitation to make powder, and control the original crystal material of the raw material to be less than 0.3 μm;

[0035] (3) Use a conventional high-energy ball mill to refine the particles so that the particle size is ≤0.7 μm;

[0036] (4) Adopt conventional spray-drying granulation and multi-stage sieving to make the granulation full without gaps and good fluidity;

[0037] (5) Formed by conventional isostatic pressing with a pressure > 150MPa;

[0038] (6) Sintering by conventional low-temperature rapid sintering technology, so that the crystal grains in the porcelain a...

example 2

[0040] Example 2. The ceramic plunger for medical equipment is completed by the following raw materials and steps:

[0041] raw material selection

[0042] (1) According to the following formula ingredients

[0043] AL 2 o 3 70%

[0044] Y 2 o 3 +CeO 2 +Nb 2 o 5 5.6%

[0045] MgO 0.3%

[0046] ZrO 2 24.1%

[0047] The production steps are the same as Example 1.

example 3

[0048] Example 3. The ceramic plunger for medical equipment is completed by the following raw materials and steps:

[0049] raw material selection

[0050] (1) According to the following formula ingredients

[0051] Y 2 o 3 +CeO 2 +Nb 2 o 5 56%

[0052] ZrO 2 94%;

[0053] The production steps are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com