Method for implementing leather fibre areosis and expansion by using supercritical carbonic anhydride

A carbon dioxide, leather fiber technology, applied in small raw hide/large raw hide/leather/fur treatment, leather/skin/leather/raw hide chemical treatment equipment, small raw hide/large hide/leather hide/fur chemical treatment, etc. Dry skin is difficult to return water, difficult to recycle and other problems, to achieve the effects of improved physical properties, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Soak the dry sheepskin in water to remove inorganic impurities on the surface and inside of the leather, dry it in a vacuum oven at 40°C for 4 hours after drying. Cut the large dry skin into 1cm×3cm blocks and medium-sized standard tensile splines, and do SEM and tensile experiments respectively.

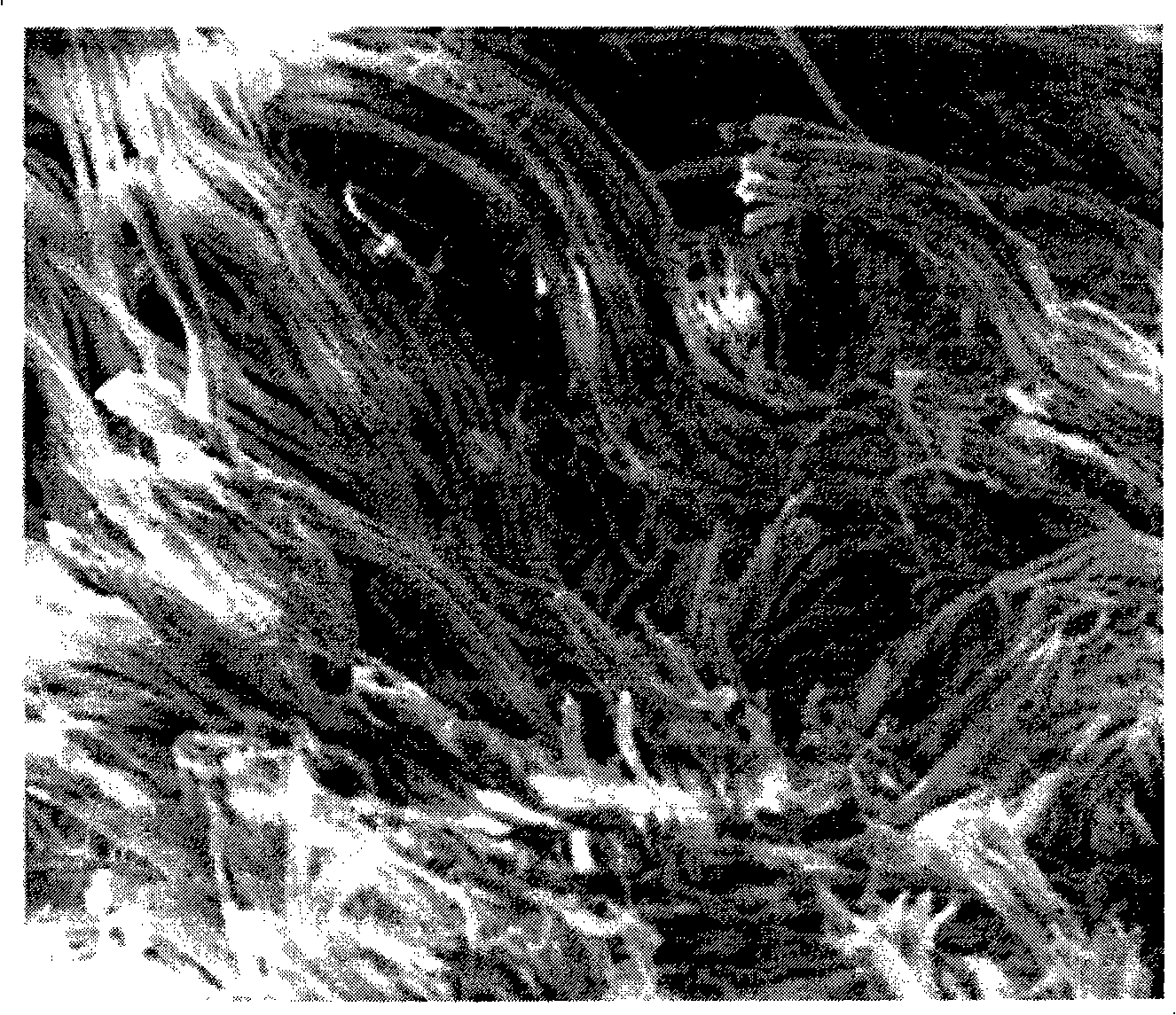

[0023] Place the dry sheepskin slice sample at the bottom of a 50ml autoclave, seal the autoclave and transfer it to a heating mantle with a constant temperature of 38°C, introduce a small amount of carbon dioxide, drain the air in the autoclave, and then close the release valve ; Inject CO into the autoclave 2 To 12MPa, stop injecting carbon dioxide, close the inlet valve, hold constant temperature and pressure for 3 hours, then quickly depressurize to normal pressure, the decompression time is controlled at 6s, open the kettle and take out the dry sheepskin sample. The SEM electron micrographs of dry sheepskin before and after treatment are shown in figure 1 with figure...

Embodiment 2-5

[0025] In the autoclave, feed carbon dioxide to pressures of 8MP, 10Mpa, 14Mpa, and 16Mpa respectively, and the others are the same as in Example 1.

Embodiment 6-7

[0027] The temperature of the constant temperature heating mantle was adjusted to 33°C and 43°C respectively, and other operations were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com