Method for producing special fastener

A production method and fastener technology, which is applied in the production field of special fasteners, can solve the problems that the production process of fasteners cannot meet the requirements, etc., and achieve the effect of strengthening comprehensive performance and increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

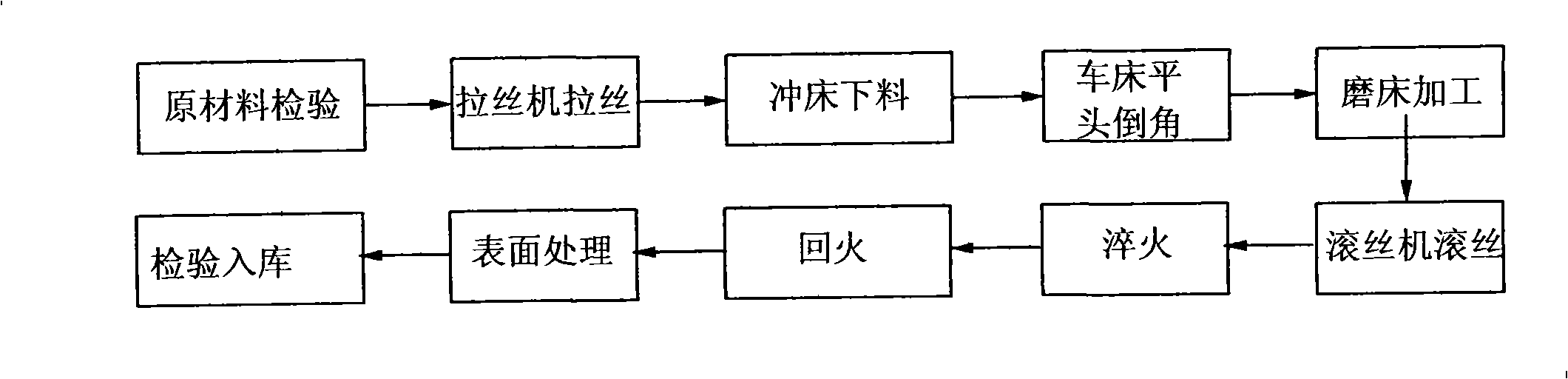

[0039] see figure 1 As shown in the process flow, the present invention mainly includes blank preparation-heat treatment process-surface treatment process-inspection storage, specifically as follows:

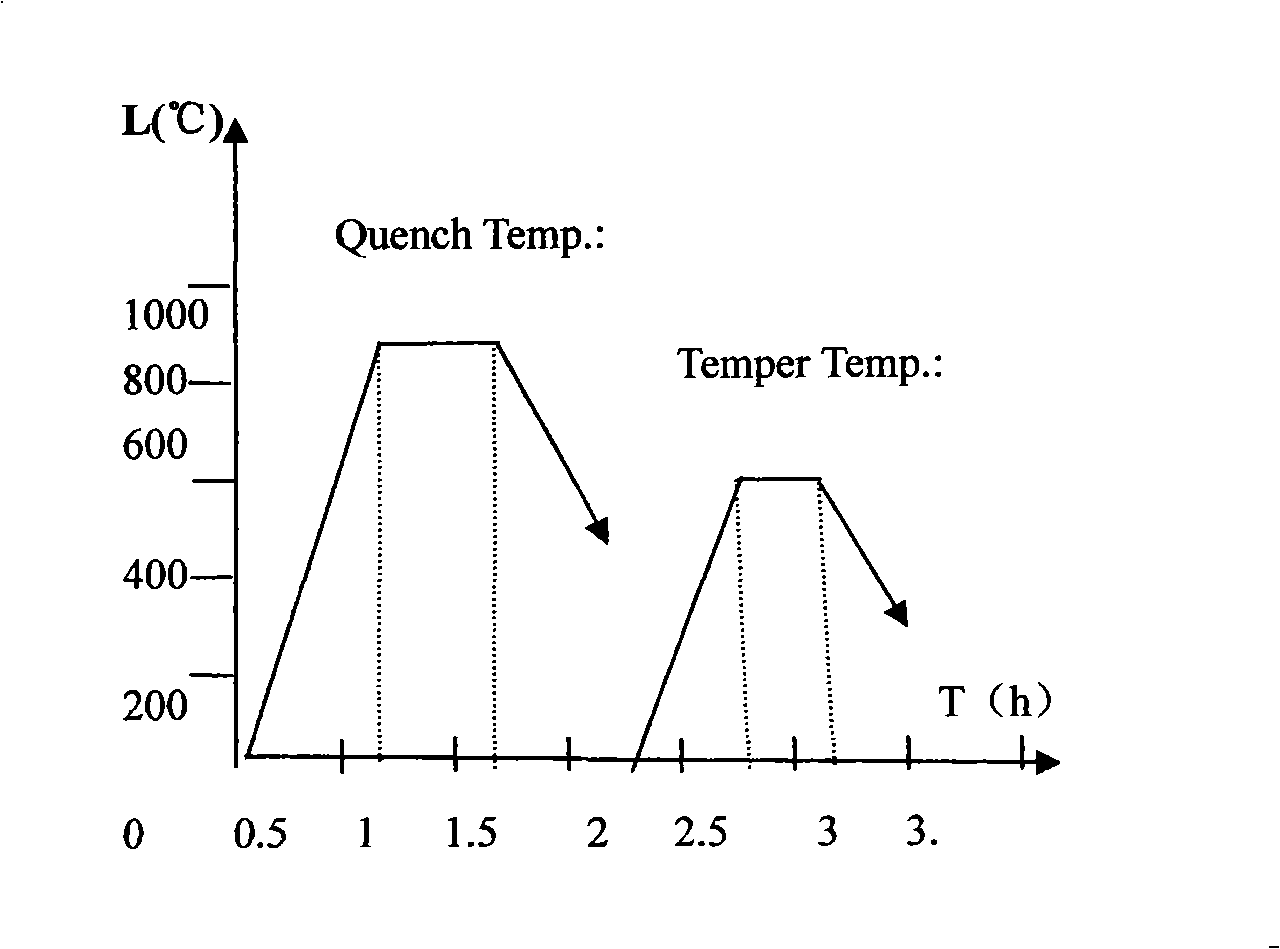

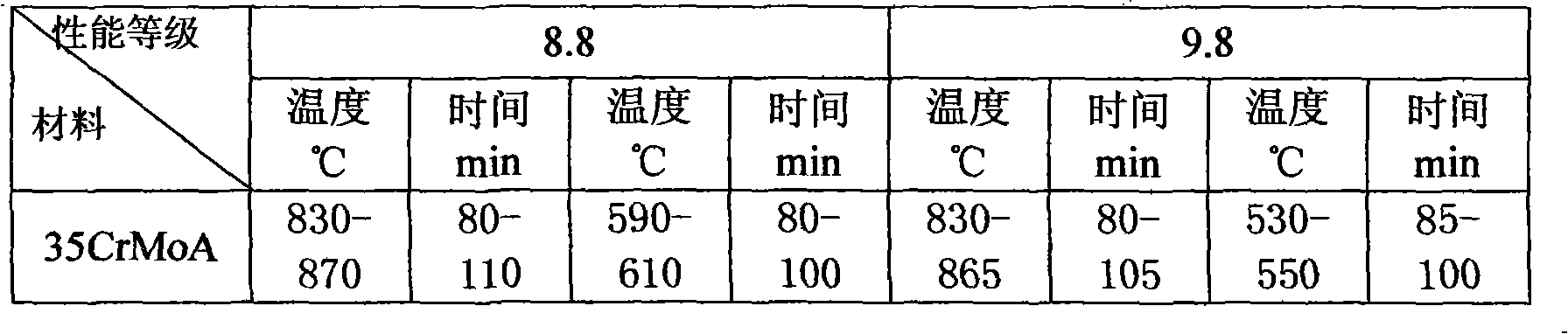

[0040] Using domestic 42CrMoA as the raw material, the deep-sea fastener blanks are prepared through raw material inspection, punching, forging, lathe plane chamfering, turning the outer diameter of the thread blank, thread rolling machine rolling, and the blank before quenching The surface of the workpiece is machined to prevent decarburization of the workpiece, so that the surface of the blank is kept bright, and then the quenching test is carried out, and the quenching crack is inspected by the naked eye, and the metallographic inspection is performed regularly to correct the furnace temperature, and then the prepared fastener blank is In the continuous controllable atmosphere tempering quenching furnace, brine is used as the quenching medium, and under the protection of met...

Embodiment 2

[0042] The technical process of this embodiment is the same as that of Embodiment 1, except that water is used as the quenching medium, and the quenching and holding time is 60 minutes.

Embodiment 3

[0044] The technical process of this embodiment is the same as that of Embodiment 1, except that oil is used as the quenching medium, and the quenching and holding time is 120 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com