Fuel oil and lubricating oil heat exchanger of light aircraft engine

A technology for aero-engines and heat exchangers, applied in engine lubrication, indirect heat exchangers, engine components, etc., can solve the problems of difficult processing, heavy heat exchangers, high density, etc., and achieve high fin efficiency and high heat transfer The effect of areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

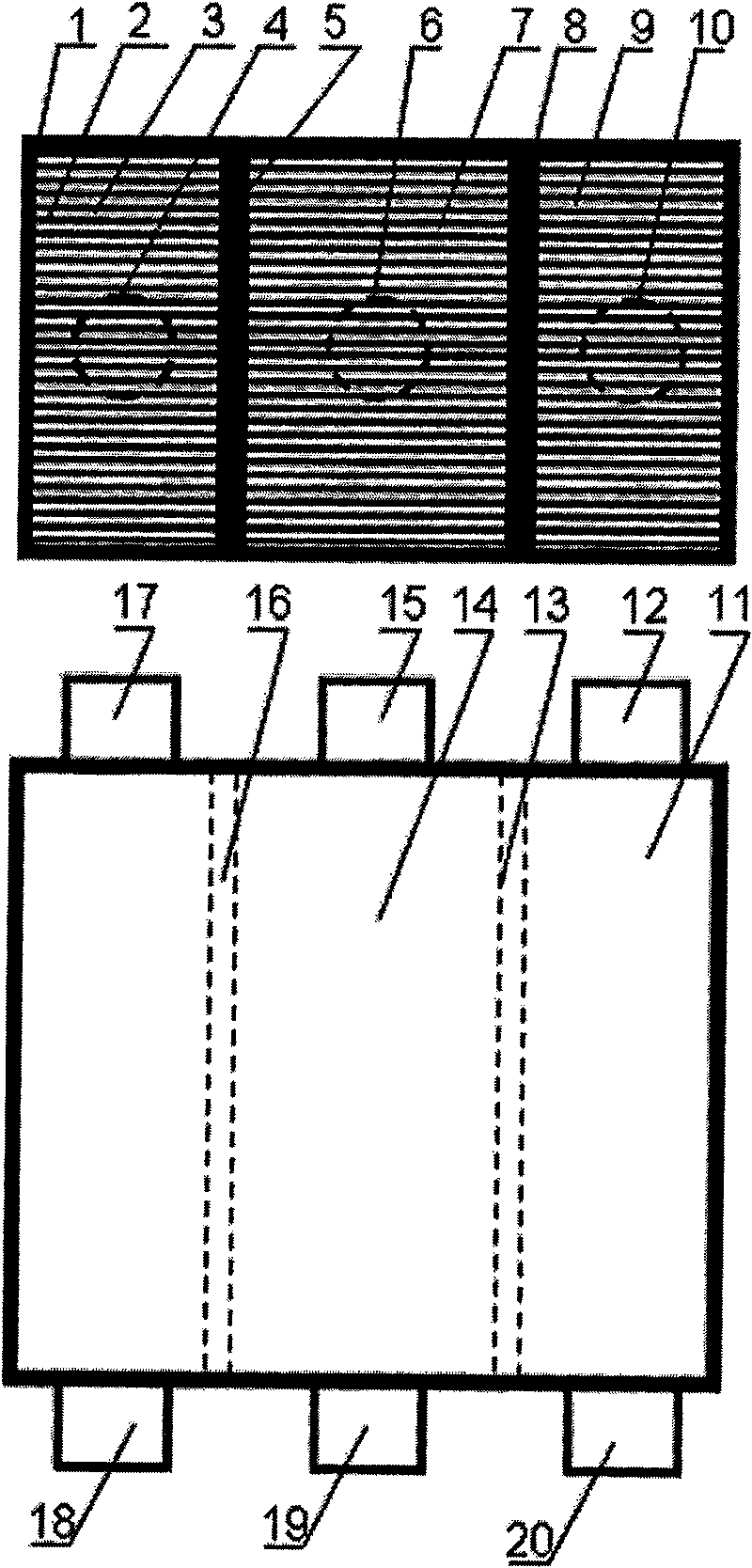

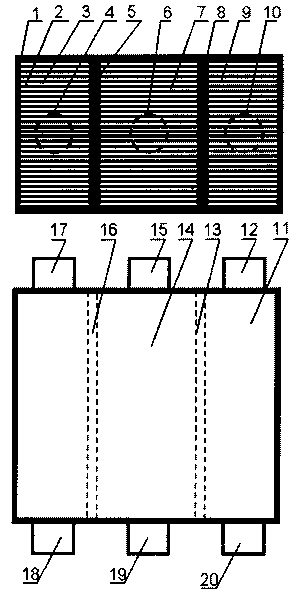

[0018] A light-duty aero-engine lubricating oil / fuel heat exchanger, which is composed of many aluminum sheets (or copper sheets) with the same structure and a thickness of 0.2-0.4mm stacked on top of each other to form the core of the heat exchanger. According to the fuel flow and resistance requirements, the core can be divided into several fuel and lubricating oil passages, such as figure 1 In the illustrated embodiment, there is one lubricating oil passage and two fuel passages. There are lubricating oil inlet and outlet joints corresponding to the lubricating oil passage on the box body, and fuel oil inlet and outlet joints corresponding to the fuel passage.

[0019] see figure 1 The preferred implementation example of the utility model shown.

[0020] The lubricating oil that needs to be cooled is introduced into the lubricating oil channel 7 (14) of the heat exchanger core through the lubricating oil inlet joint 19, and after exchanging heat with the sheet, it is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com