Nano granule water purifying material for removing bacteria and virus, and preparation thereof

A nanoparticle and bacteria technology, applied in the field of sewage purification and wastewater, can solve the problems of high cost, difficult regeneration and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

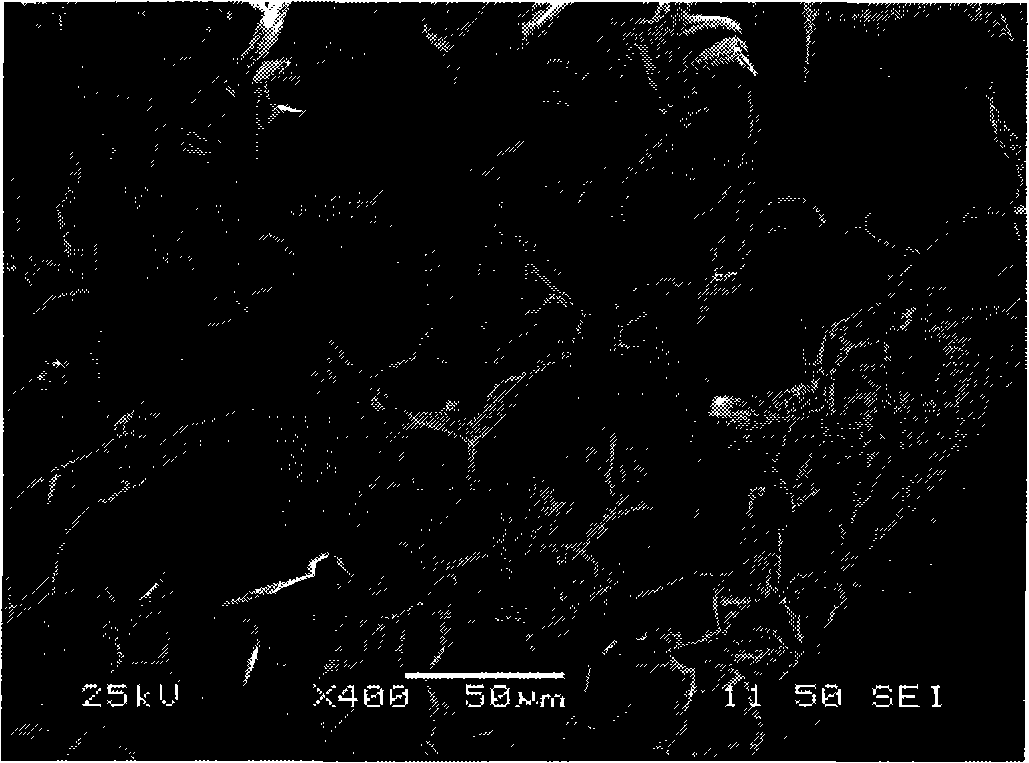

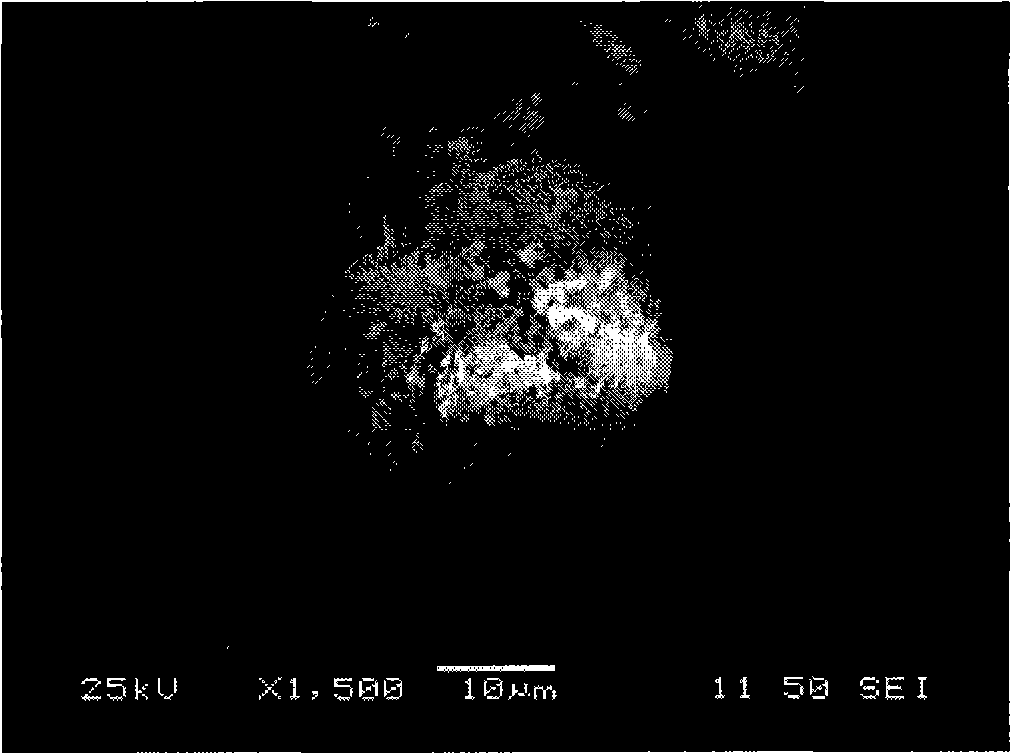

Embodiment 1

[0066] Take 30g of pretreated quartz sand (60-80 mesh) into 200mL secondary deionized water and mix evenly, add 1.5g / L boric acid 10mL, mix evenly for 20min, at 80°C, add nano-aluminum powder ( Prepared by the electric explosive wire method, the average particle size is 45nm) 2.6g, placed in an ultrasonic tank for ultrasonic oscillation (K-100 ultrasonic cleaner, ultrasonic frequency 235KHz) for 30min; then add 2g / L tetrahexyl orthosilicate to the mixture Esters in ethanol (alcohol, ester volume ratio 2.5:1) solution 50mL, continue ultrasonic stirring treatment for 20min, stop ultrasonic, keep warm with the tank for 3 hours; filter the prepared solid-liquid mixture with Buchner funnel, filter material with secondary After washing with deionized water several times until there is no filter residue in the washing liquid, the filter material is moved to a drying oven and dried at 60° C. for 10 hours to obtain 30.8 g of AlO(OH) nanoparticle water purification material.

[0067] Th...

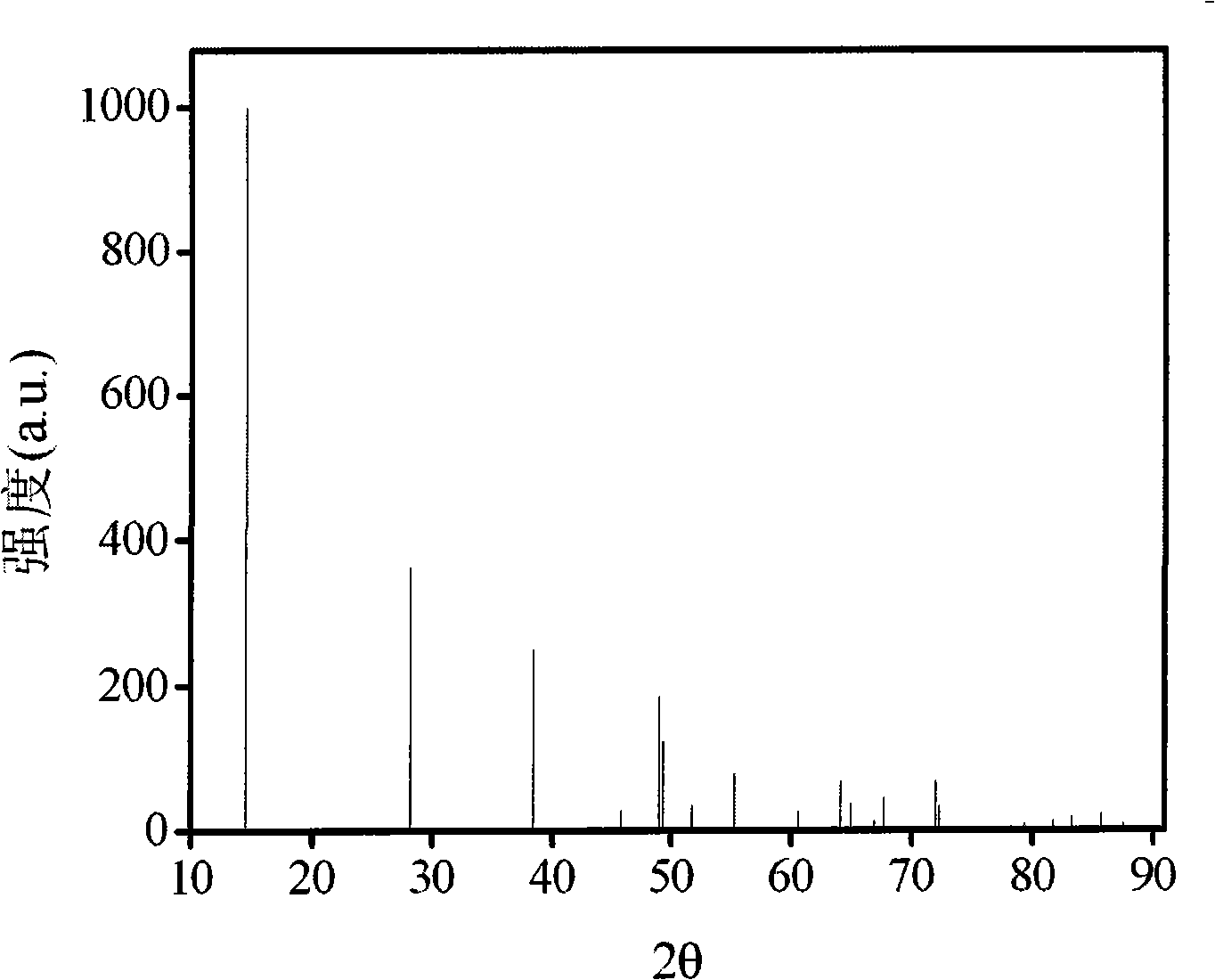

Embodiment 2

[0069] Move the sample prepared in Example 1 into a muffle furnace, raise the temperature to 450°C at a rate of 10°C / min, roast for 2.5 hours, and then cool to room temperature with the furnace to obtain 30.6g γ-Al 2 o 3 Nano water purification material. Filter coating composition is γ-Al 2 o 3 , the coating accounts for 1.96% of the total weight of the substrate and the coating, the average particle size of the coating is 92nm, and the specific surface area is 205m 2 / g, the coating thickness is 1.42 μm.

Embodiment 3

[0071]Take 30g of pretreated quartz sand (40-60 mesh) into 200ml of secondary deionized water and mix evenly, add 20ml of 4g / L sodium salicylate, mix evenly for 30min, then add 4.56 g nano-iron powder (made by electric explosive wire method, average particle size 85nm), placed in an ultrasonic tank for ultrasonic oscillation (ultrasonic frequency 235KHz) for 45min, and then adding 4.5g / L ethanol solution of tetrahexyl orthosilicate to the mixture (alcohol, ester volume ratio 3:1) 55mL, continue ultrasonic oscillation for 30min, turn off the ultrasonic wave, and keep warm with the tank for 5h; filter the solid-liquid mixture prepared above with a Buchner funnel, and wash the filter material with deionized water twice. After the washing solution has no filter residue, the filter material is dried in a drying oven at a temperature of 80° C. for 10 hours to obtain 30.88 g of FeOOH nano-particle water purification material.

[0072] The filter coating composition is FeOOH, the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com