Hot galvanizing plate and manufacturing method therefor

A hot-dip galvanizing and plate technology, applied in hot-dip galvanizing process, heat treatment equipment, chemical instruments and methods, etc., can solve the problems of poor oil storage performance, scratches, and affecting service life, and achieve good roughness uniformity, Effect of reducing roll consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

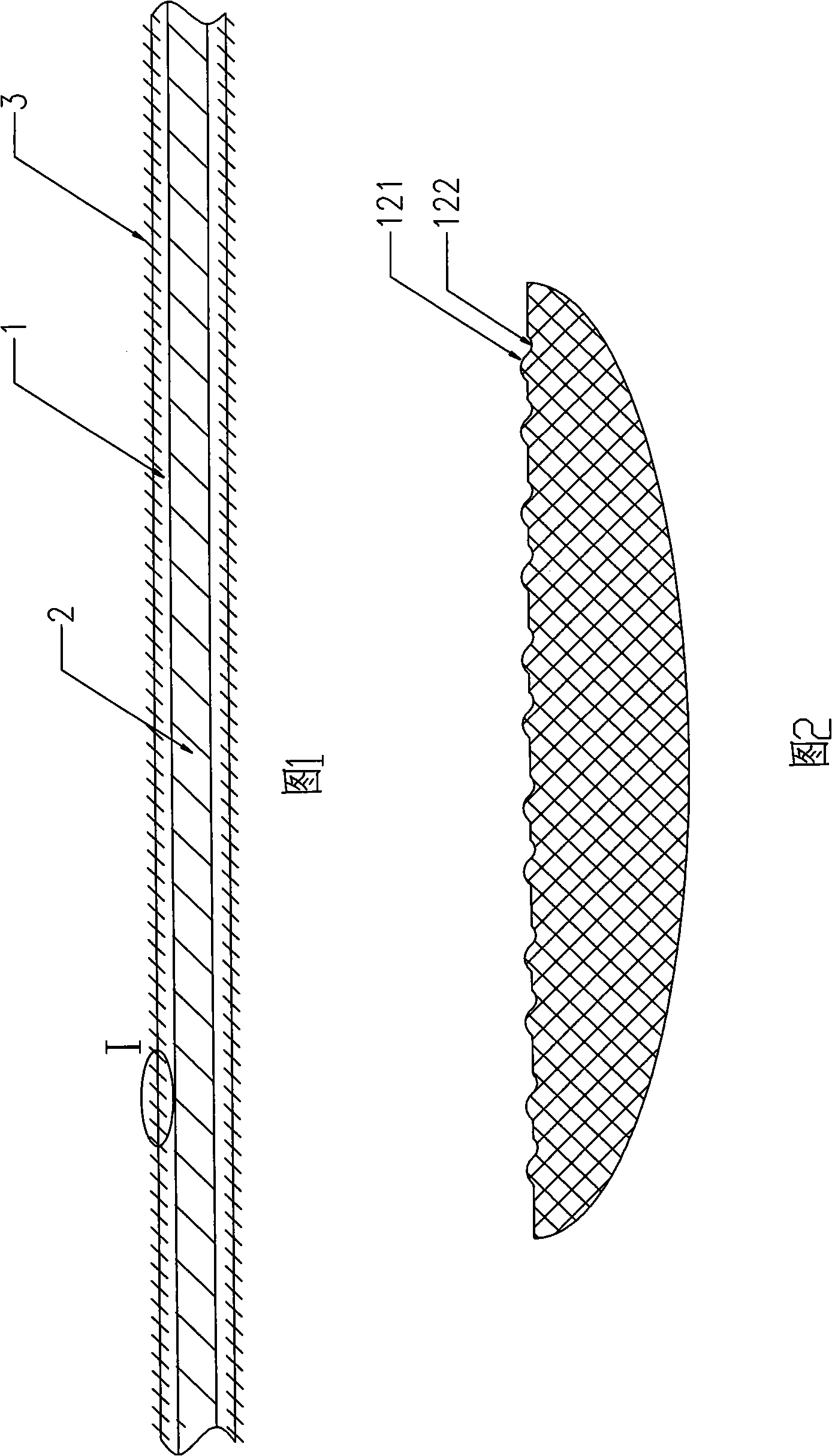

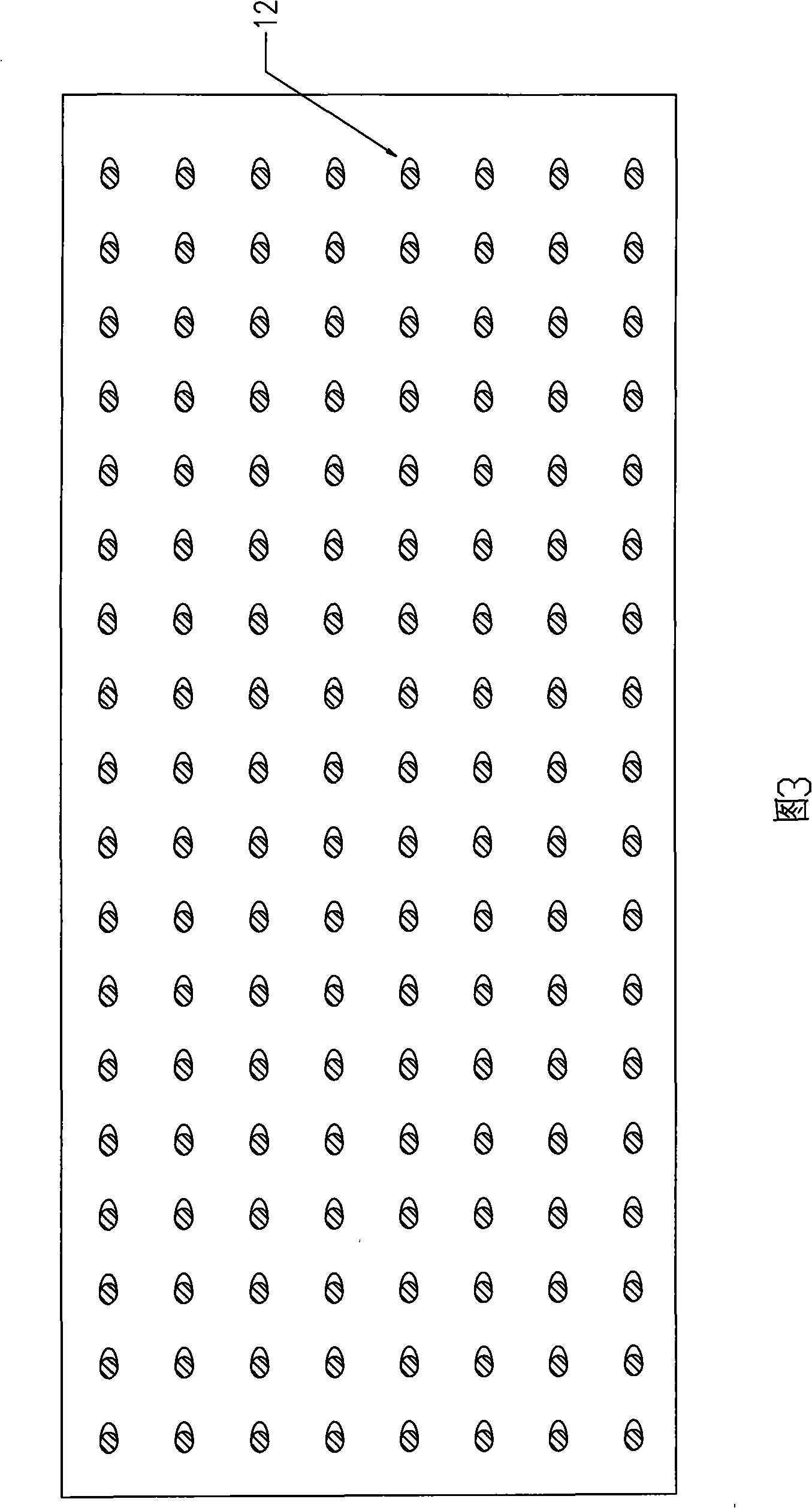

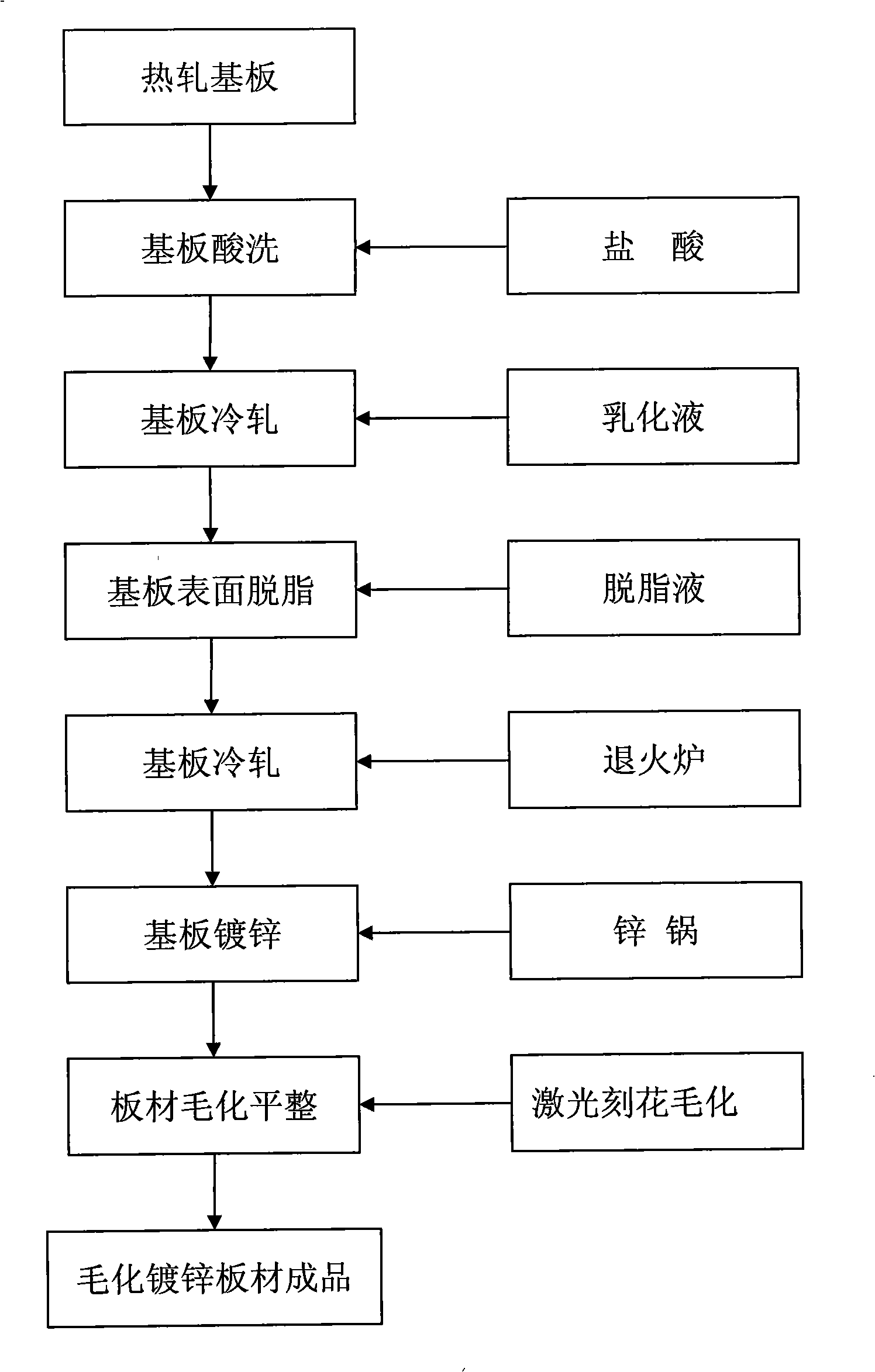

[0024] to combine Figure 4 The preparation process in the above is used for production, and hot-rolled steel sheets are selected as the steel sheet layer for galvanized sheet processing.

[0025] a. Pickling of hot-rolled substrate: use concentration of 0.1mol L -1 Clean the surface of the hot-rolled steel plate with a dilute hydrochloric acid solution to remove the rust and impurities on the surface of the hot-rolled steel plate, so that the surface of the hot-rolled steel plate reveals a silvery white metallic luster without foreign matter.

[0026] b. Pickling substrate cold rolling: the hot-rolled steel plate is cold-rolled through the cold-rolling unit, and the emulsion is sprayed on the surface of the steel plate during the cold-rolling process. The emulsion can cool and lubricate the steel plate to make the steel plate uniform in thickness.

[0027] c. Degreasing the surface of the rolled hard substrate: Use a metal degreasing agent with a free alkali point of 20 to cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com