Constant-current contactless magnetizing packing method and apparatus for chain riveting

A non-contact, flow technology, applied in packaging, conversion equipment with intermediate conversion to AC, electromagnets, etc., can solve the problems of short life of magnetization circuit, large circuit impact, affecting life, etc., to improve reliability. With the degree of flexibility, stable packaging quality, good demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

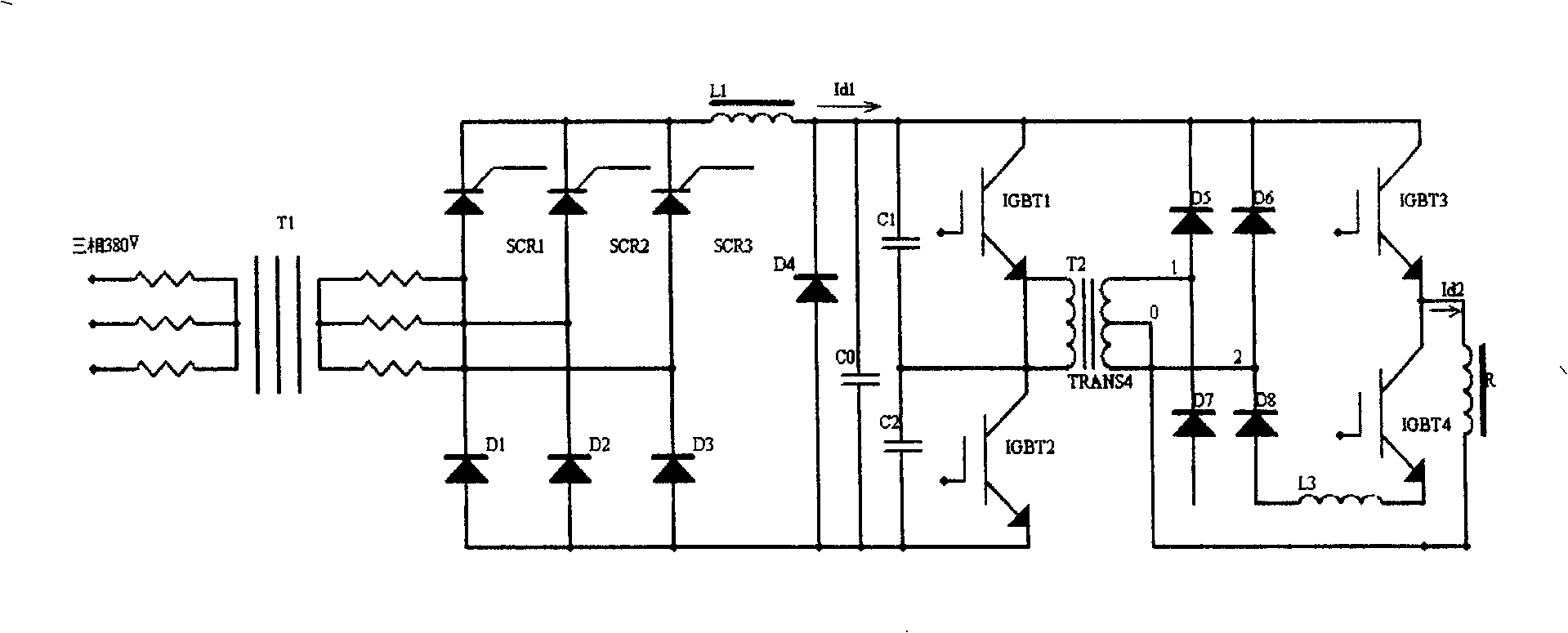

[0029] A constant-current non-contact plus magnetic nail row packaging method and equipment, mainly using a constant-current thyristor rectifier power supply as the excitation power supply, using an IGBT inverse commutation circuit to realize the non-contact commutation of the excitation current, and adopting programmable control The controller performs numerical control on the output current of the excitation power supply and the commutation time.

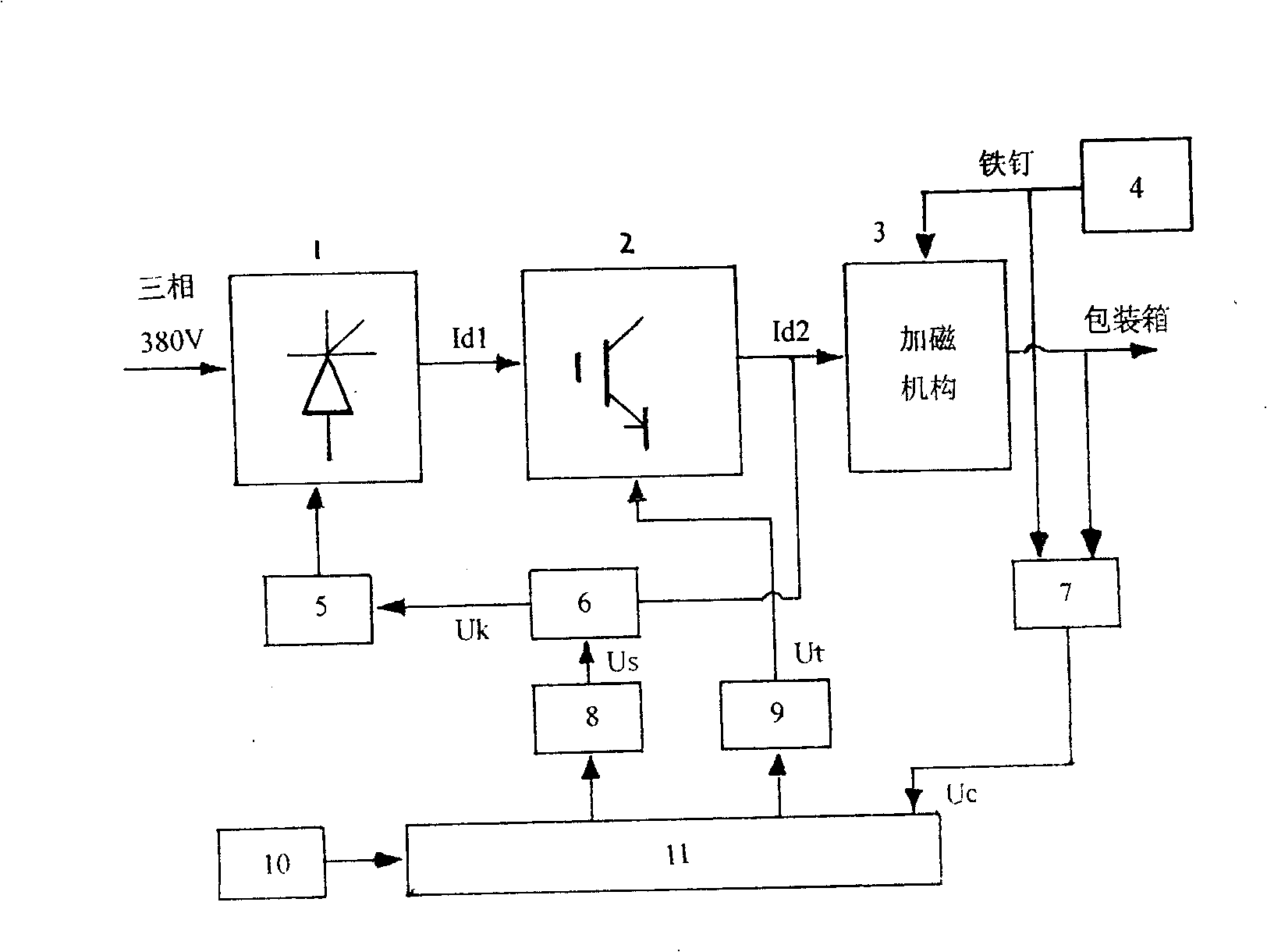

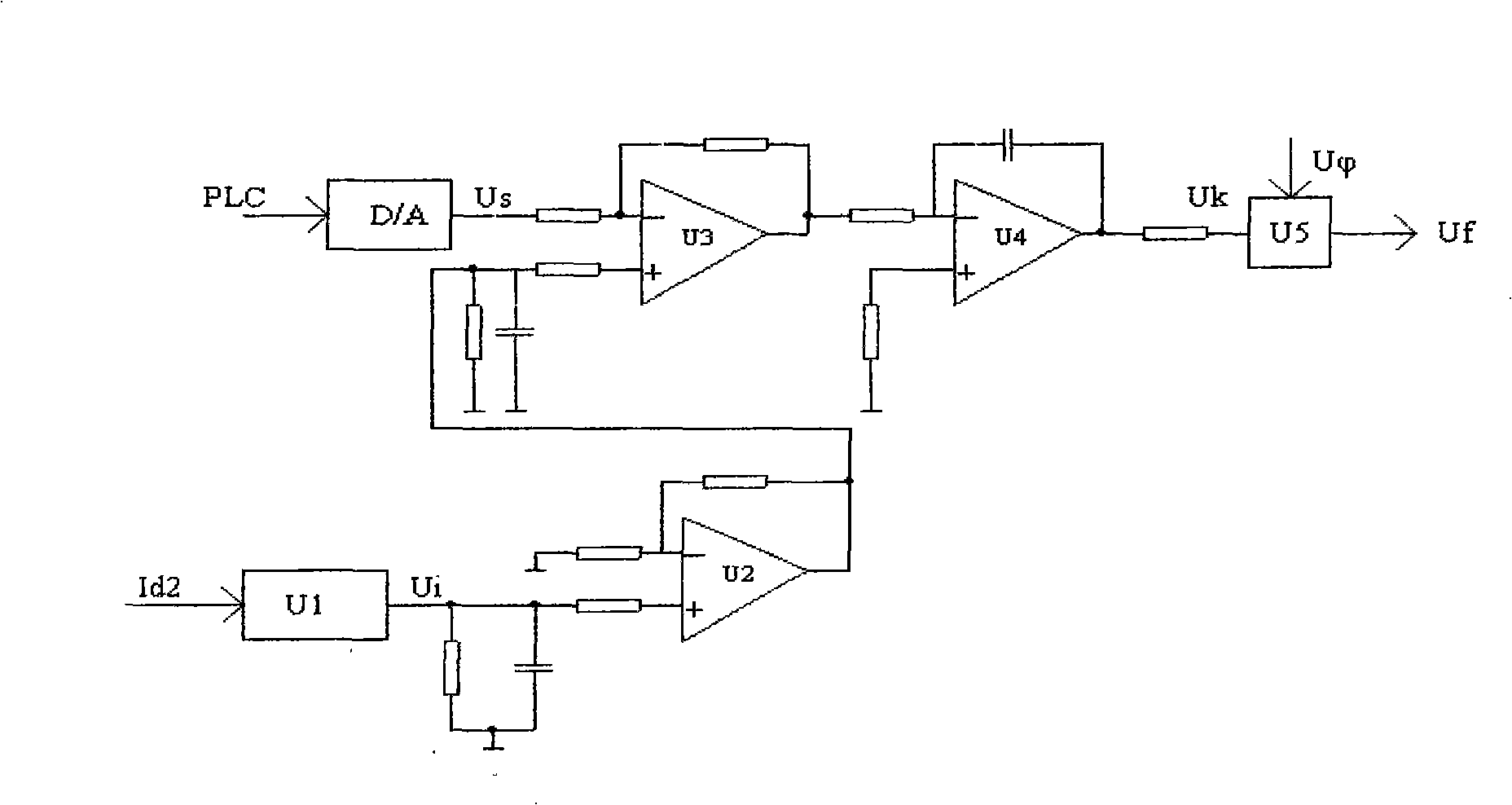

[0030] Such as figure 1 As shown, the three-phase bridge type thyristor full-wave rectifier circuit 1, the current feedback amplifier circuit 6, the three-phase trigger circuit 5 and the computer D / A interface module 8 form a constant current thyristor rectifier power supply. Among them, the three-phase bridge thyristor rectifier circuit full-wave rectifies the three-phase power frequency AC po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com