Electromagnetic inductive composite aluminum foil seal gasket and manufacturing process therefor

A composite aluminum foil, electromagnetic induction technology, applied in the direction of adhesive type, film/sheet adhesive, epoxy resin glue, etc., to achieve the effect of improved printing quality, excellent moisture resistance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

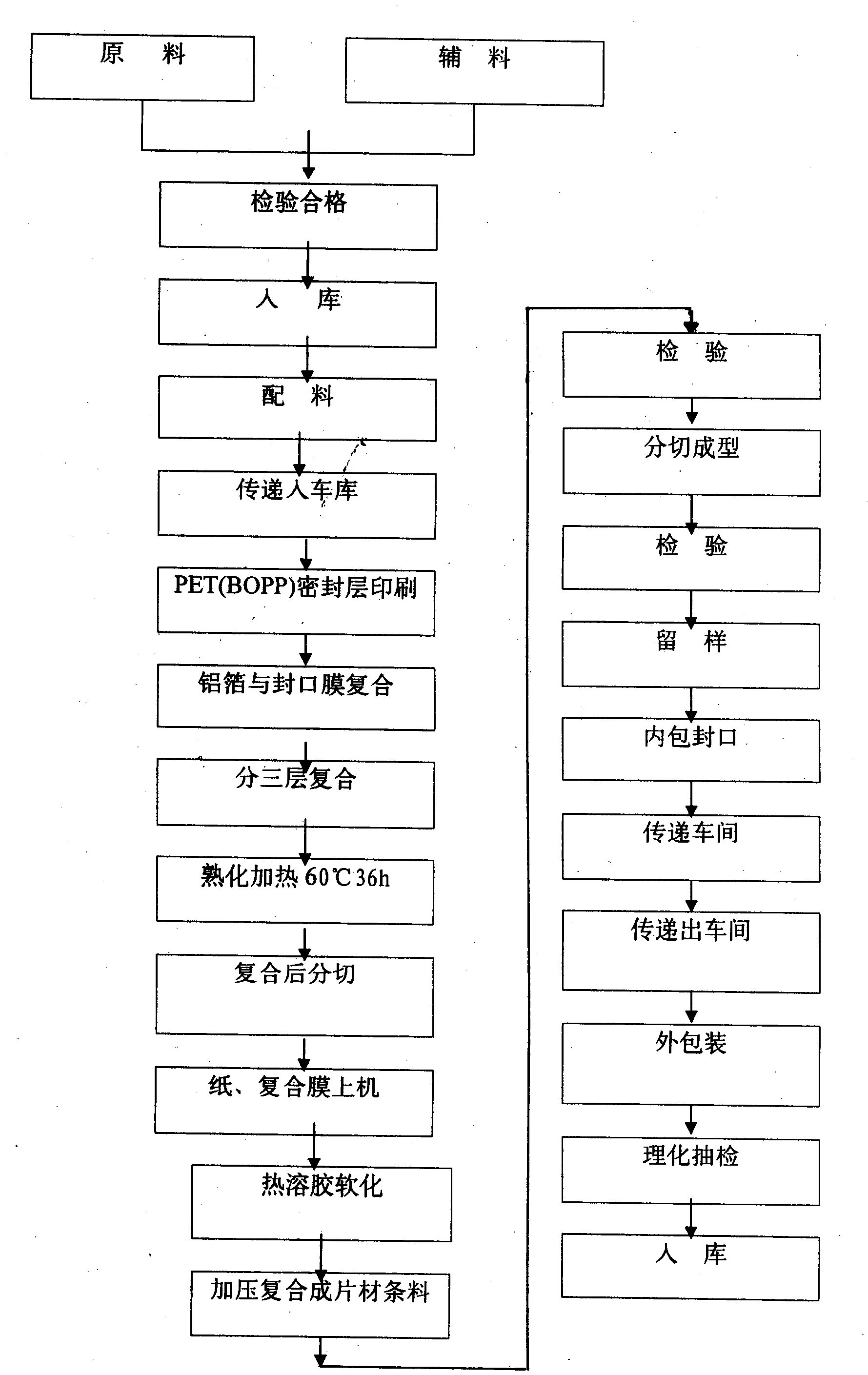

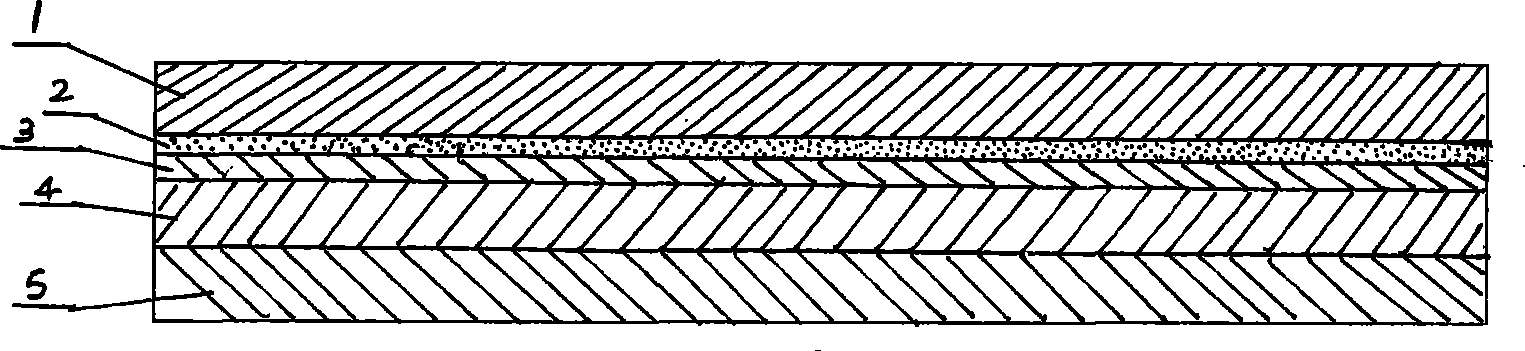

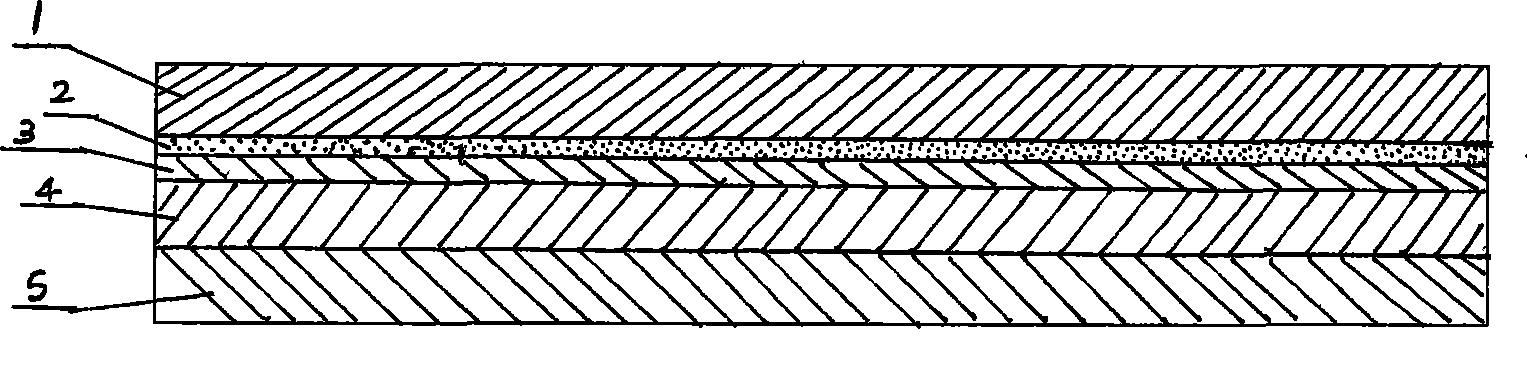

[0029] Such as figure 1 The electromagnetic induction composite aluminum foil sealing gasket shown is composed of tissue paper as the base material layer 1 and the aluminum foil layer 4 bonded by the adhesive layer 2. The upper surface of the aluminum foil layer 4 is coated with a sealing film layer 3, and the lower surface is coated with There is an adhesive sealing layer 5, and the adhesive layer 2 is made of rosin or terpene resin added to paraffin wax accounting for 1%-5% of the total weight of the adhesive. The sealing film layer 3 is made of BOPP or PET film, and characters or patterns are reverse printed on the surface of the BOPP or PET film. Adhesive is coated on the lower surface of the adhesive sealing layer 5 . The adhesive is mixed with 60%-90% epoxy resin and 10%-40% vinyl acetate. Add magnetic powder accounting for 1 / 10,000 to 2 / 10,000 to the adhesive sealing layer or adhesive. It is advisable to use the same raw material as the bottle mouth material for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com