Nano-silver nonwoven cloth and application thereof to sterilizing filter element

A non-woven fabric and nano-silver technology, which is applied in the direction of fixed filter elements, filtration separation, textiles and papermaking, etc., to achieve the effects of health assistance, safe and reliable use, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

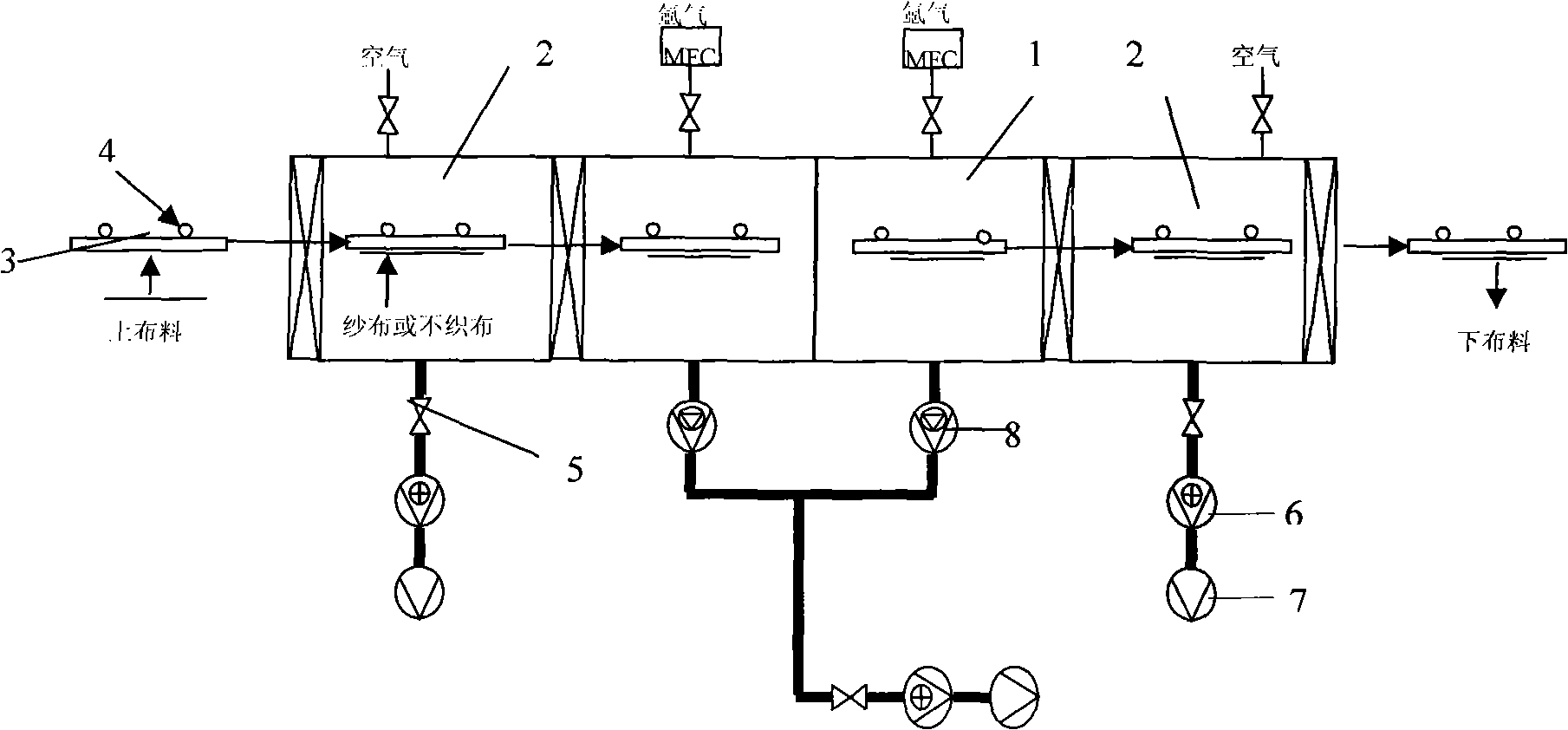

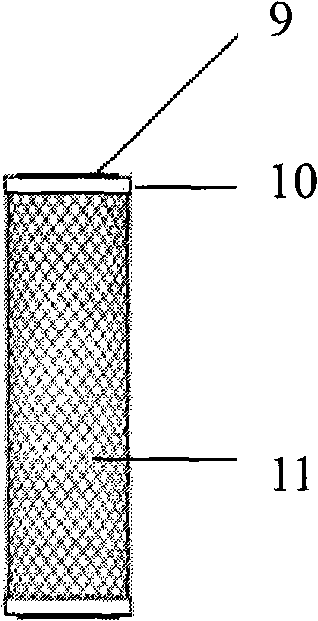

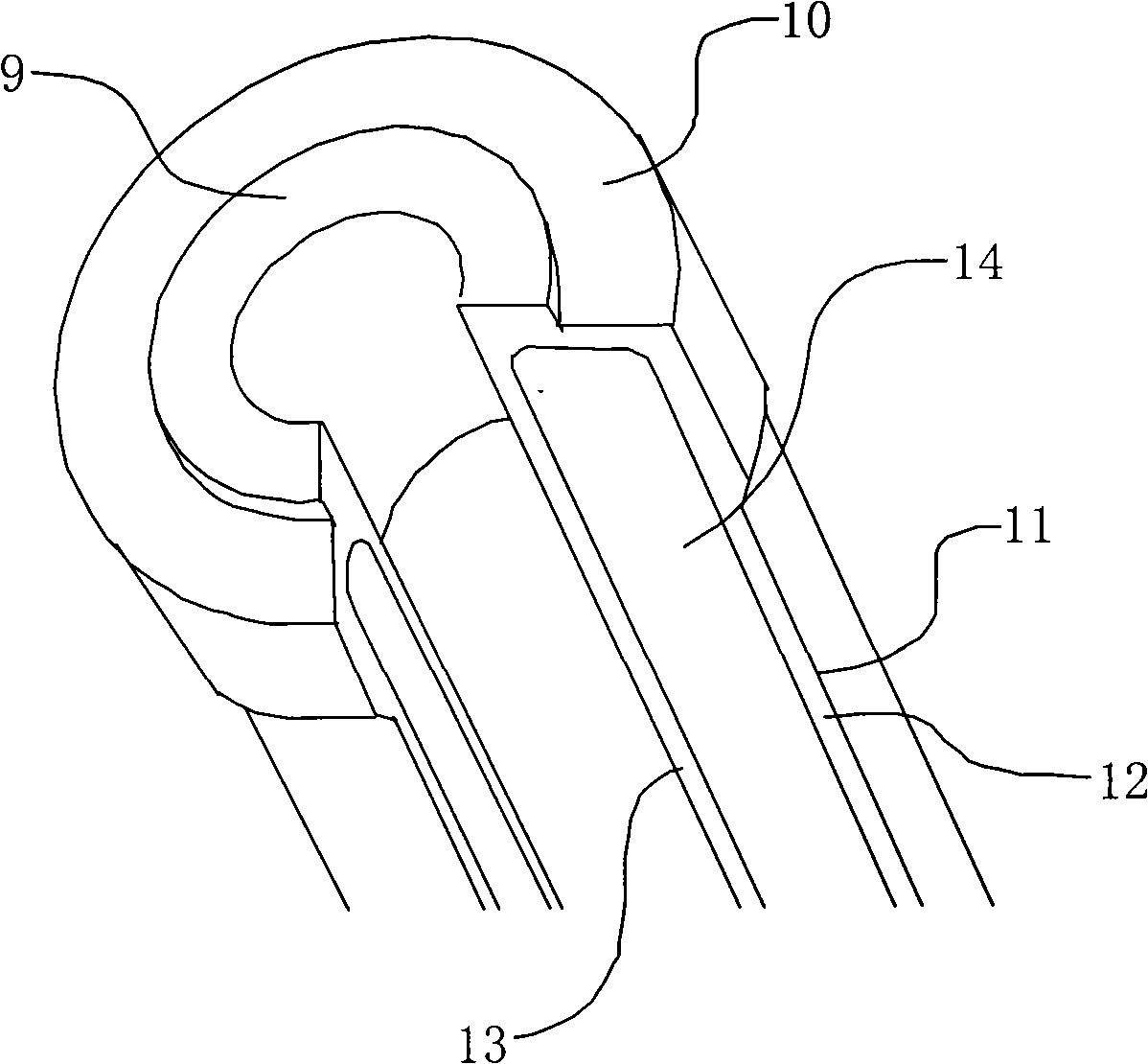

Method used

Image

Examples

Embodiment 1

[0038] Choose a piece of non-woven fabric;

[0039] Control the air pressure in the vacuum chamber at 6×10 -6Torr, when the non-woven fabric reaches the sputtering chamber, fill the sputtering chamber with argon gas at a flow rate of 1mtorr / min, and start the DC power supply to supply a DC power supply with a power of 5Kw to the magnetron sputtering target to form argon gas Plasma: The silver atoms on the silver target are splashed out by the plasma bombardment, and deposited on one surface of the non-woven fabric to form a nano-scale silver film. The aforementioned predetermined power is controlled at 0.5w / cm in the power density value of the silver target (electrical power / area of the surface of the silver target bombarded by the plasma) 2 ~25w / cm 2 between, so that the thickness of the formed nano-silver is between 20 and 40 nanometers (the silver film is formed by stacking silver atoms on the surface of the non-woven fabric one by one), because at this scale, it can ha...

Embodiment 2

[0041] Choose a piece of non-woven fabric;

[0042] Control the air pressure in the vacuum chamber at 10×10 -6 Torr, when the non-woven fabric reaches the sputtering chamber, fill the sputtering chamber with argon gas with a flow rate of 10mtorr / min, start the DC power supply, and supply a DC power supply with a power of 20Kw to the magnetron sputtering target to form argon gas Plasma: The silver atoms on the silver target are splashed out by the plasma bombardment, and deposited on one surface of the non-woven fabric to form a nano-scale silver film. The aforementioned predetermined power is controlled at 0.5w / cm in the power density value of the silver target (electrical power / area of the surface of the silver target bombarded by the plasma) 2 ~25w / cm 2 between, so that the thickness of the formed nano-silver is between 30 and 40 nanometers (the silver film is formed by stacking silver atoms on the surface of the non-woven fabric one by one), because at this scale, it ca...

Embodiment 3

[0044] Choose a piece of non-woven fabric;

[0045] Control the air pressure in the vacuum chamber at 8×10 -6 Torr, when the non-woven fabric reaches the sputtering chamber, fill the sputtering chamber with argon gas at a flow rate of 20mtorr / min, and start the DC power supply to supply a DC power supply with a power of 15Kw to the magnetron sputtering target to form argon gas Plasma: The silver atoms on the silver target are splashed out by the plasma bombardment, and deposited on one surface of the non-woven fabric to form a nano-scale silver film. The aforementioned predetermined power is controlled at 0.5w / cm in the power density value of the silver target (electrical power / area of the surface of the silver target bombarded by the plasma) 2 ~25w / cm 2 between, so that the thickness of the nano-silver formed is between 35 and 40 nanometers (the silver film is formed by stacking silver atoms on the surface of the non-woven fabric one by one), because at this scale, it can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com