Measuring apparatus of wafer lower fluid film intermediate variable in CMP process

A technology of liquid film and measuring device, which is applied in the field of laser measurement, can solve problems such as inability to measure, and achieve the effect of eliminating environmental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

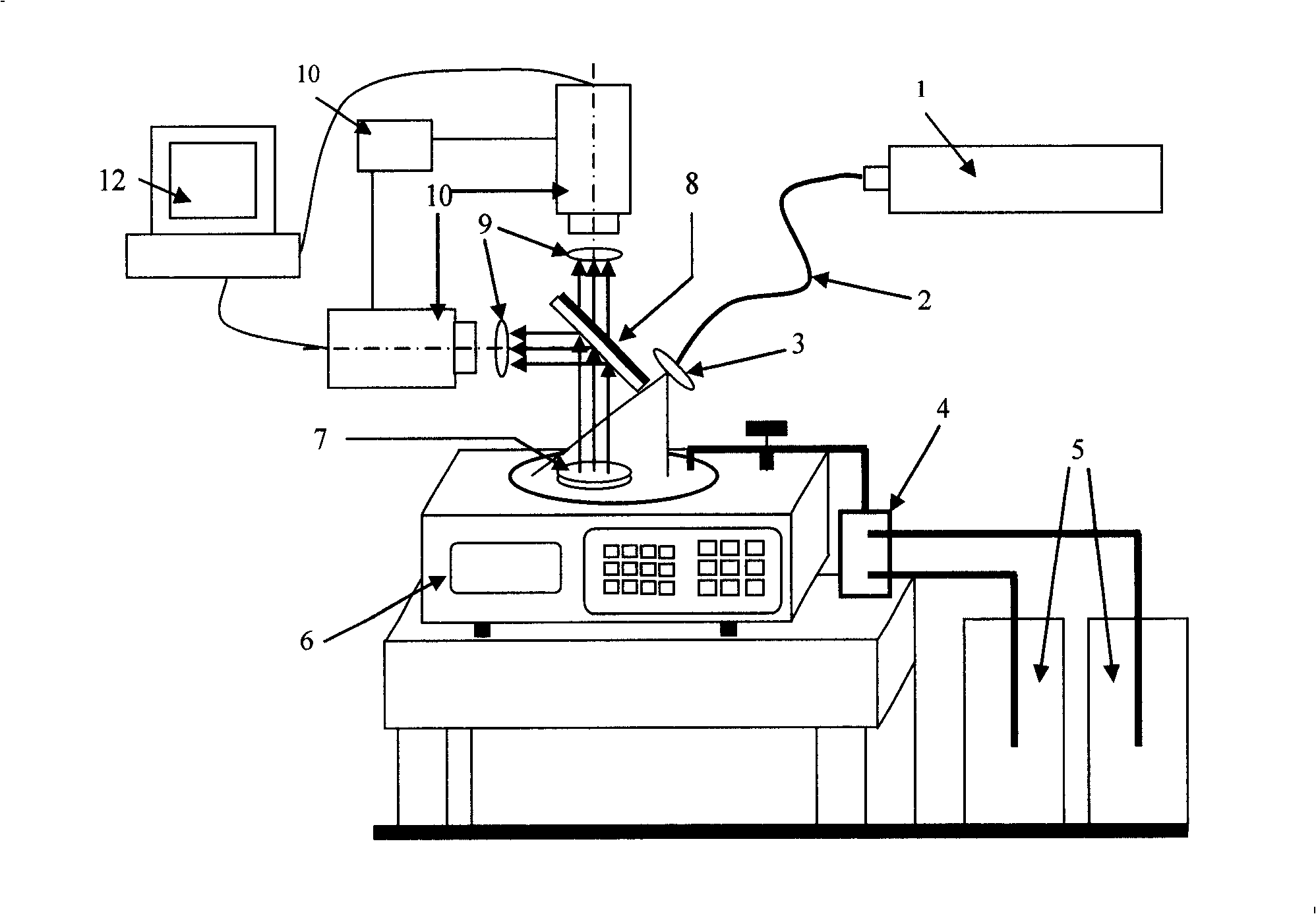

[0019] refer to figure 1 , a measuring device for the intermediate variable of a liquid film under a wafer in a CMP process, comprising a laser 1, a beam splitter 8, an optical filter 9, a camera 10, a computer 12 for calculation and measurement, and a device for providing two kinds of fluorescent materials The polishing liquid supply mechanism of the polishing liquid, the laser 1 is connected to the diverging lens 3 through the optical fiber 2, the exit optical range of the diverging lens 3 covers the liquid film under the wafer 7, and the beam splitter 8 is located above the wafer 7, Two outgoing directions of the beam splitter 8 are provided with two optical filters 9, and each of the optical filters 9 is opposite to a respective camera 10, and the camera 10 is connected with the computer 11 data, and the computer 12 includes image processing for the fluorescence i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com