Fluid food browning testing method

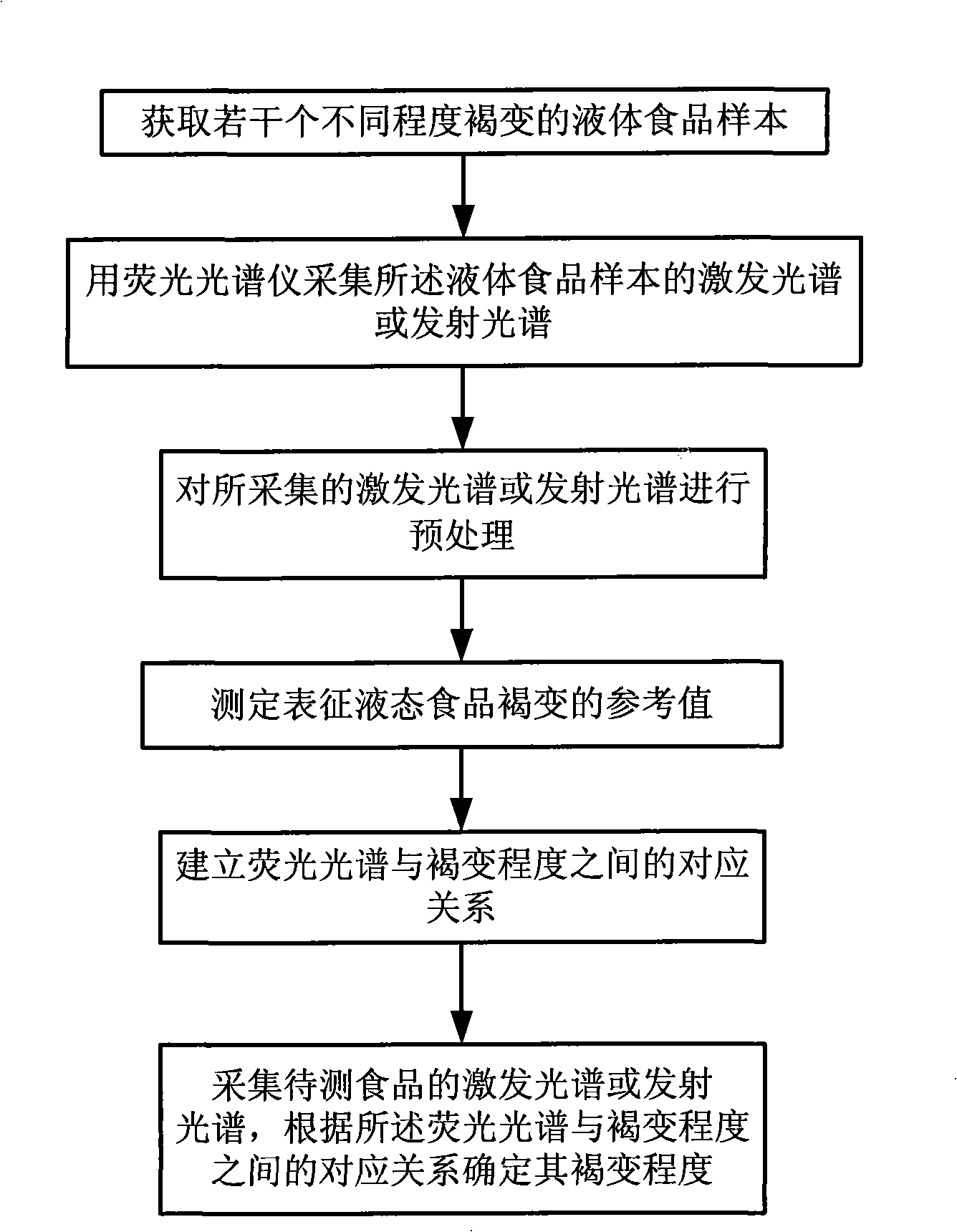

A detection method and liquid food technology, applied in the field of food analysis, can solve problems such as complicated analysis process, difficult online analysis, time-consuming and labor-intensive, and achieve the effects of short collection time, high sensitivity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

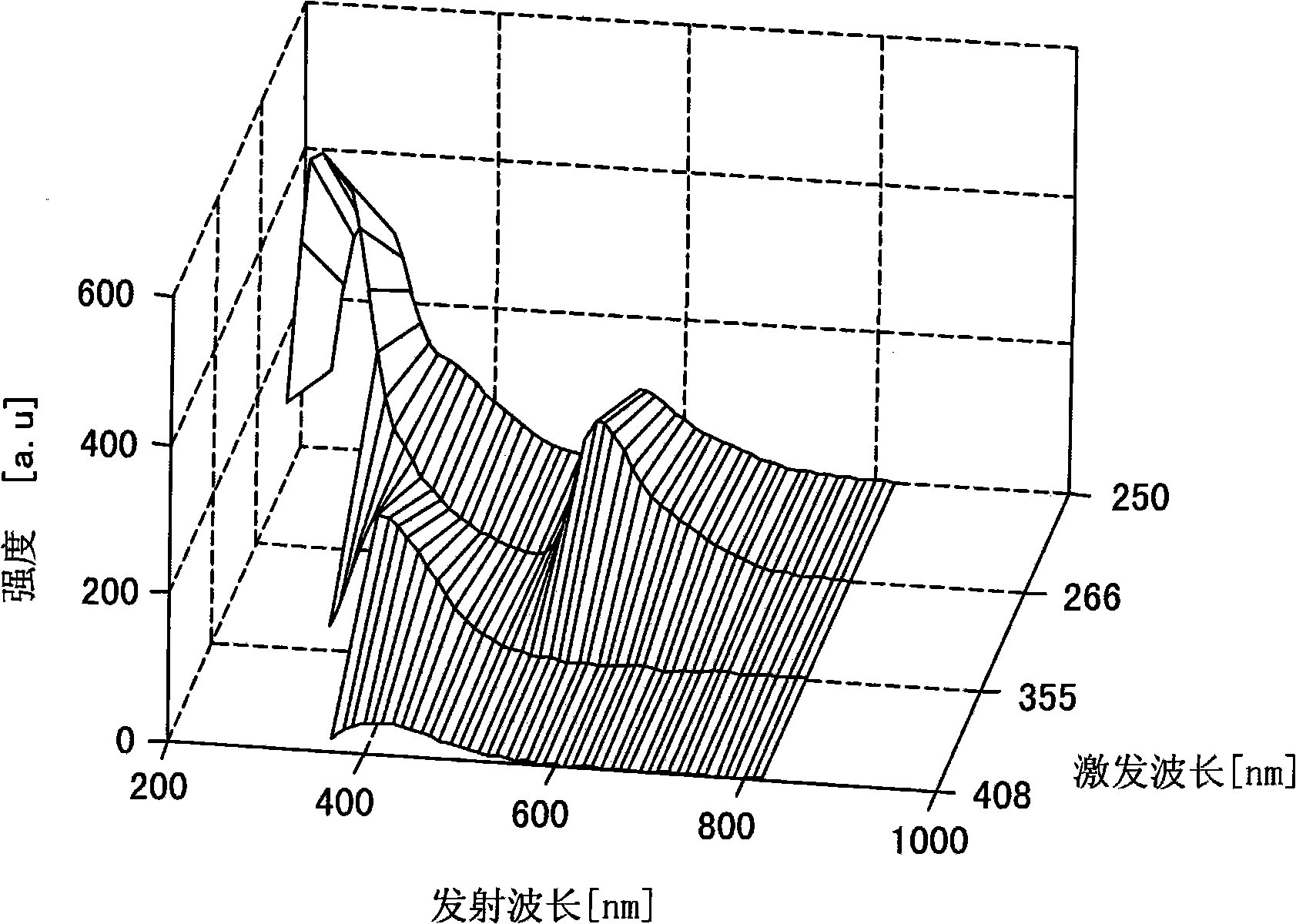

[0033] This embodiment is a qualitative and quantitative detection method for enzymatic browning of apple juice based on a three-dimensional fluorescence matrix.

[0034] The method mainly includes the following steps:

[0035] Sample preparation: Collect Pinova apples from a local orchard in Potsdam, Germany, squeeze the juice, centrifuge and filter to obtain 30 clarified apple juice samples, divide each sample into two parts, and one part of the sample is used for immediate fluorescence spectroscopy Collect and measure the browning reference value; then store it in a 20°C incubator for 4 days to cause enzymatic browning, and then collect the fluorescence spectrum to measure the browning reference value; the other part is heated in a water bath at 80°C for 10 After rapid cooling in 10 minutes, store in a 20°C incubator for 4 days to cause slight non-enzymatic browning, and then collect fluorescence spectrum to measure the reference value of browning. In this step, the measure...

Embodiment 2

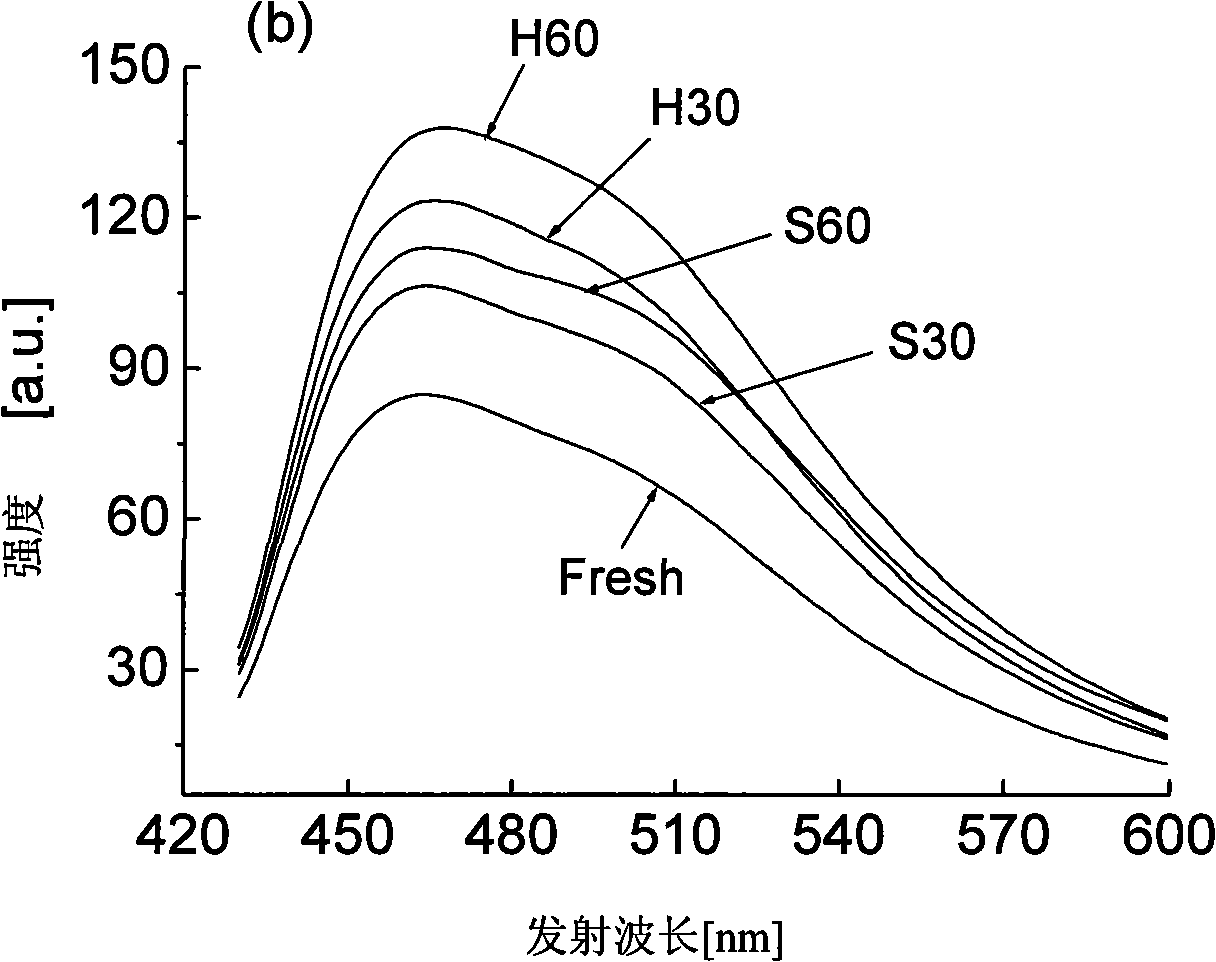

[0046] This embodiment is a method for qualitative classification and quantitative prediction and detection of non-enzymatic browning of apple juice based on fluorescence spectrum.

[0047] The method mainly includes the following steps:

[0048] Sample preparation: Collect Pinova apples from local orchards in Potsdam, Germany, squeeze the juice, centrifuge and filter to obtain 8 clarified apple juice samples. Divide each sample into three parts. The first part of the sample is immediately collected for fluorescence spectrum and measured for browning reference value, which is recorded as "Fresh". The second and third parts are heated in a 95°C water bath for 30 minutes and 60 minutes respectively. Immediately after cooling in an ice-water bath, collect fluorescence spectra and measure browning reference values, which are recorded as "H30" and "H60" respectively. Then the heated two apple juices were stored in a thermostat at 20°C for 6 days, and then measured again, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com