Device and method for detecting battery performance of hybrid power vehicle

A hybrid vehicle and battery performance technology, applied in battery circuit devices, electric vehicles, measurement devices, etc., can solve the problems of reducing battery efficiency and life, adjusting battery working range, errors, etc., to achieve the effect of improving efficiency and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Referring to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the mutual position and connection relationship between the control system and the detection device involved, the function and working principle of each system, and the test method, will be further described. The detailed description is to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

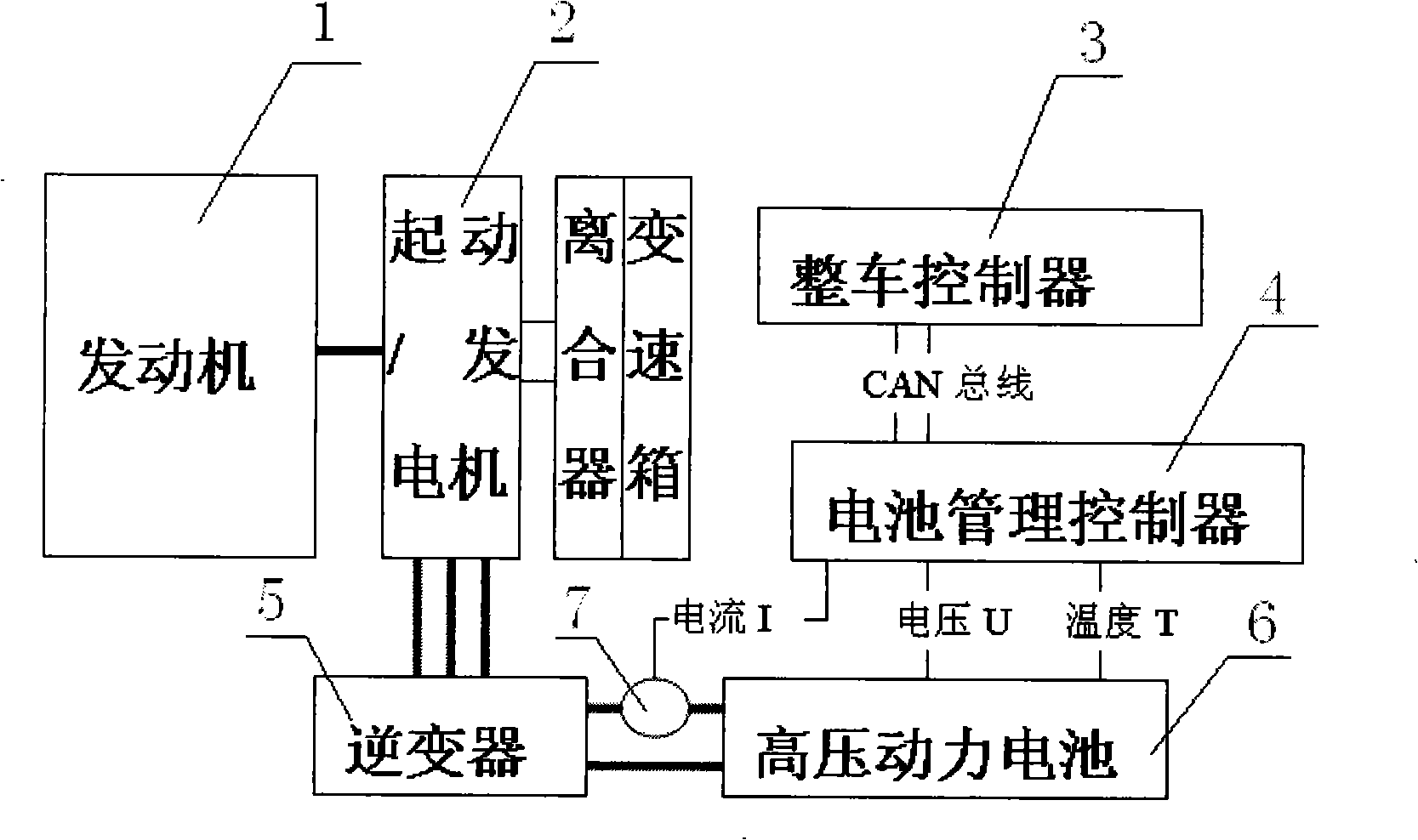

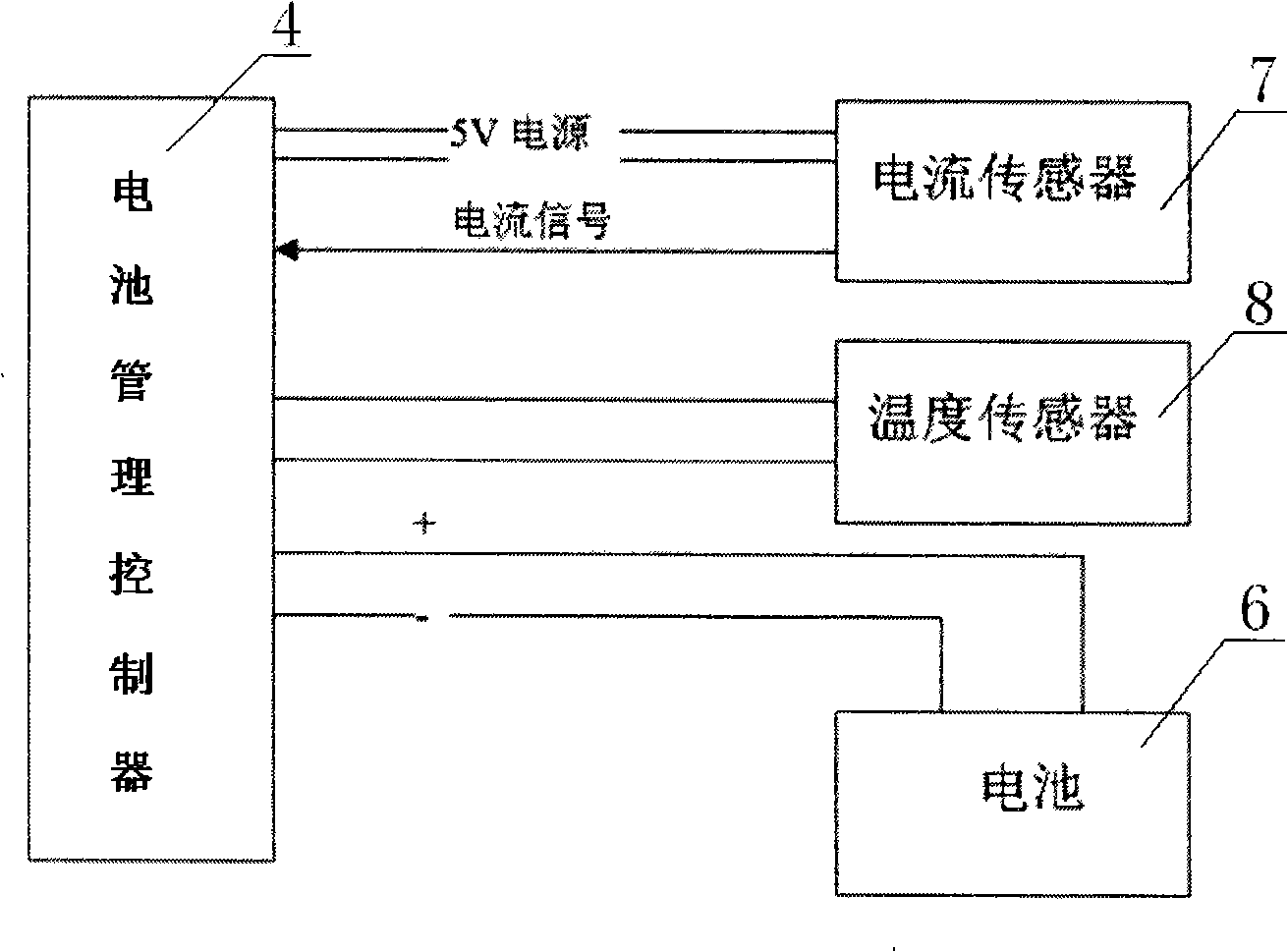

[0030] Such as figure 1 , figure 2 As shown, a battery performance detection device for a hybrid electric vehicle includes a motor 2 coaxially connected to an engine 1, an inverter 5, a vehicle controller 3, and a battery 6 electrically connected to a battery management controller 4. The battery management controller 4 described above is provided with a signal acquisition unit. The signal acquisition unit is a part of the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com