Integrated modularized slurry processing unit

A treatment device and modular technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of large floor area, poor anti-overloading ability, time-consuming installation, etc. Problems, to achieve the effect of convenient installation and management, small overall footprint, practical and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

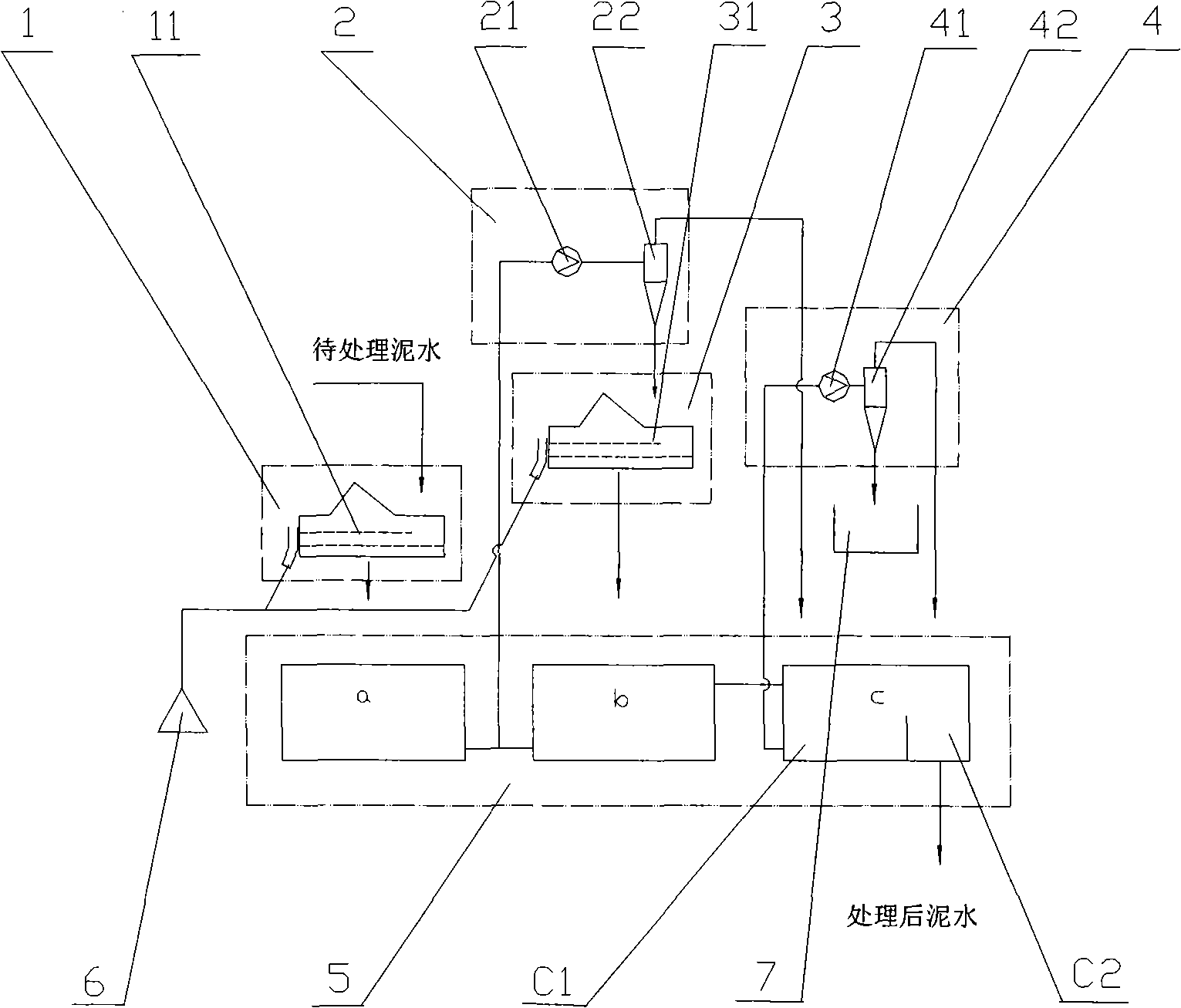

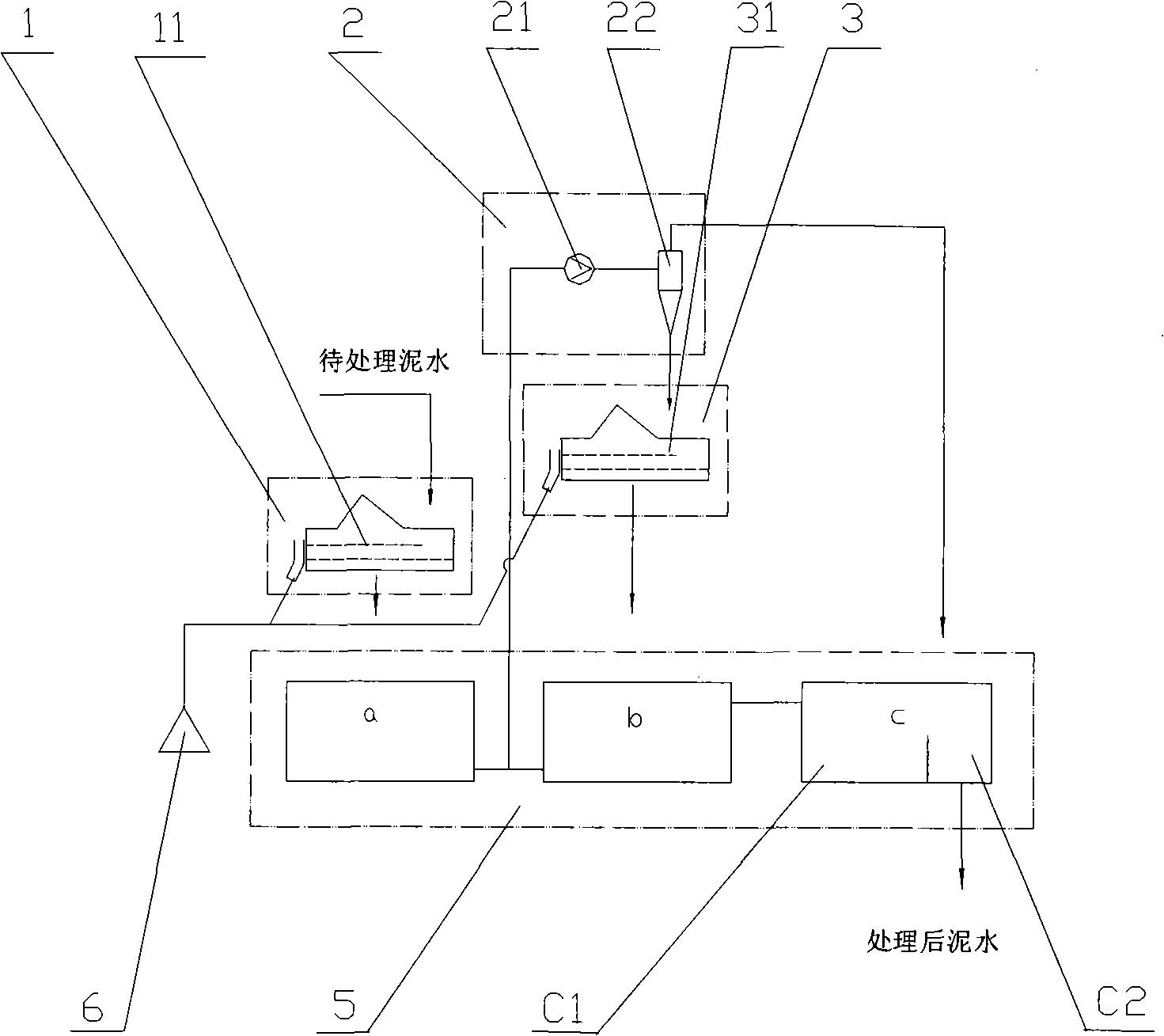

[0011] See first figure 1 Schematic diagram of the device structure of the present invention. The integrated modular sludge treatment device shown in the figure includes a vibrating screen module 1 , a desander module 2 , a dewatering screen module 3 , a desilter module 4 and a transition tank module 5 . The vibrating screen module 1 is used for pretreatment of muddy water to be treated to remove large-grained mudstones; in this embodiment, the diameter of the large-grained mudstones is greater than 4.5mm. The desander module 2 is used to carry out primary treatment to the muddy water pretreated by the vibrating screen module 1, that is, to further separate the mudstones with medium particles and above; in this embodiment, the diameter of the medium-sized mudstones is larger than 0.074mm up to 4.5mm. The dewatering screen module 3 is used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com