Method for improving appearance quality of granules made from diammonium phosphate slurry

A technology of diammonium phosphate and appearance quality, applied in the field of phosphate fertilizer and nitrogen fertilizer, can solve problems such as interfering with slurry performance, achieve the effect of round appearance, improve product grade, and improve product appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

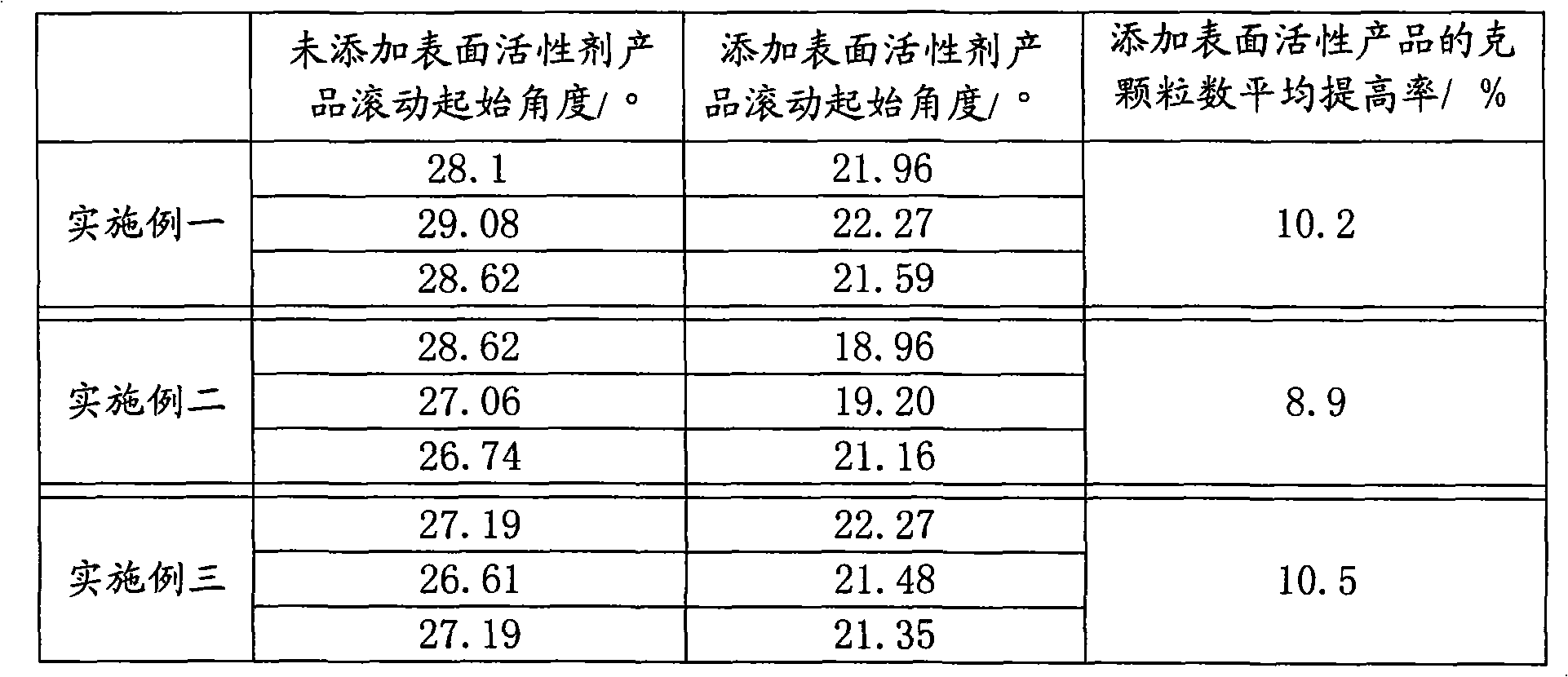

Embodiment 1

[0012] Embodiment 1 selects sodium lauryl sulfate and sodium oleate to make surfactant

[0013] Add the same amount of sodium lauryl sulfate and sodium oleate into the melting tank, and control the temperature of the melting tank at 80°C to prepare a saturated solution of surfactant for later use; pump the surfactant solution to the slurry pump with a gear pump The suction port takes over the joint, enters the slurry and mixes it, and then sprays and granulates it. Slurry flow 60m 3 / h, the surfactant solution flow rate is 9.3kg / h.

[0014] In-process control: slurry neutralization degree 1.45-1.55; slurry density 1500-1600kg / m 3 ; Slurry temperature 110 ℃ ~ 125 ℃.

Embodiment 2

[0015] Embodiment 2 selects sodium cetyl sulfonate as surfactant

[0016] Add sodium cetyl sulfonate into the melting tank, and control the temperature of the melting tank at about 90°C to prepare a saturated surfactant solution for use; pump the melted surfactant to the suction port of the slurry pump with a gear pump , into the slurry mixing, spray granulation. Slurry flow 60m 3 / h, the surfactant solution flow rate is 100kg / h.

[0017] In-process control: slurry neutralization degree 1.45-1.55; slurry density 1500-1600kg / m 3 ; Slurry temperature 110 ℃ ~ 125 ℃.

Embodiment 3

[0018] Embodiment 3 Select sodium dodecylbenzenesulfonate, sodium oleate and sodium stearate as surfactants

[0019] Add the same amount of sodium dodecylbenzenesulfonate, sodium oleate and sodium stearate into the melting tank, control the temperature of the melting tank at about 80°C, prepare a saturated surfactant solution for later use; put the melted surfactant Use a gear pump to pump it to the suction port of the slurry pump, enter the slurry and mix it, and then spray the slurry to granulate. Slurry flow 60m 3 / h, the surfactant solution flow rate is 930kg / h.

[0020] In-process control: slurry neutralization degree 1.45-1.55; slurry density: 1500-1600kg / m 3 ;Slurry temperature: 110℃~125℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com