Ultra-high non-linear photon crystal optical fiber based on narrow slit effect

A photonic crystal fiber and fiber technology, applied in nonlinear optics, cladding fiber, optical waveguide light guide, etc., can solve problems such as high nonlinear coefficient, and achieve the effect of reducing the effective mode field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

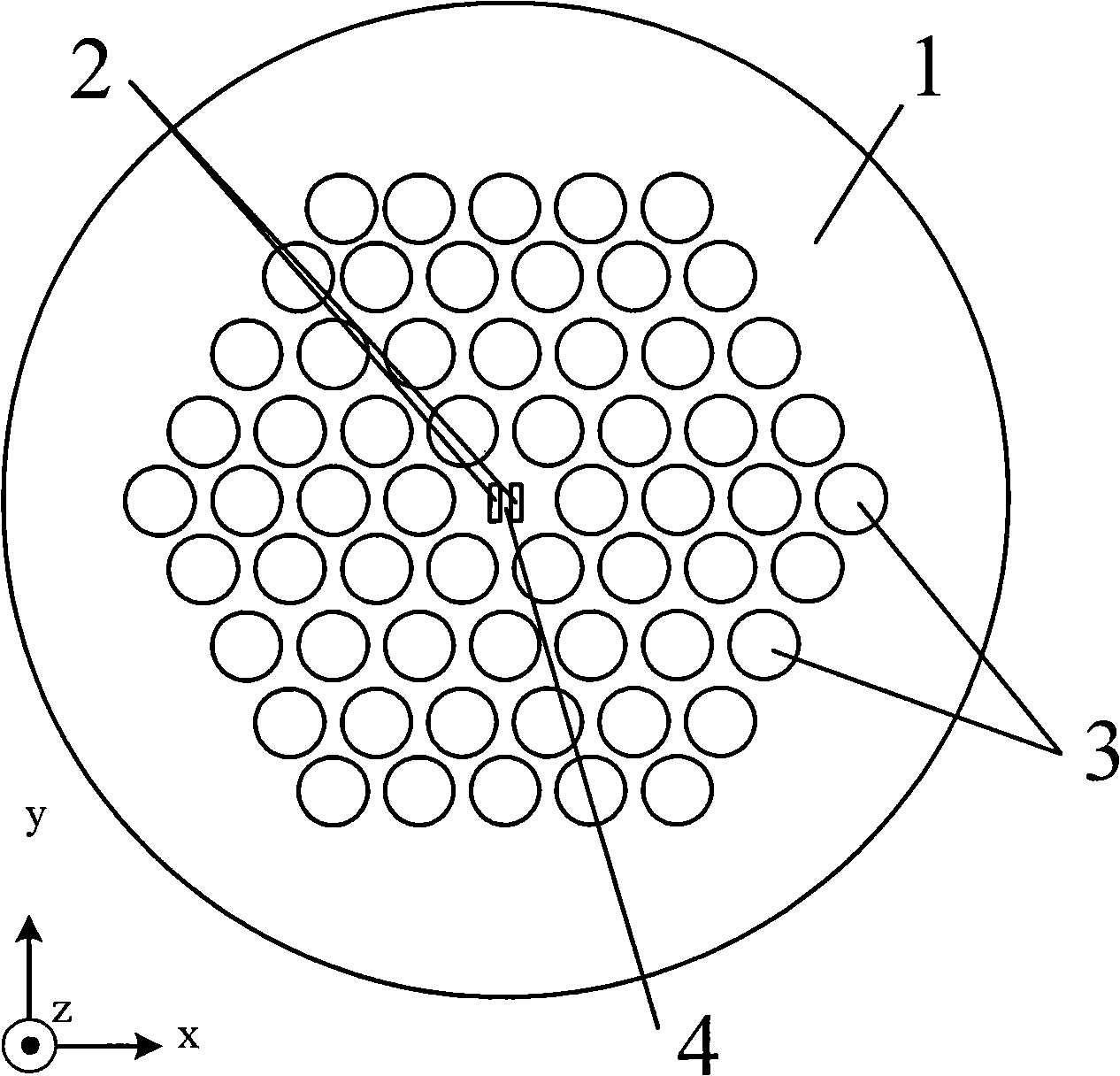

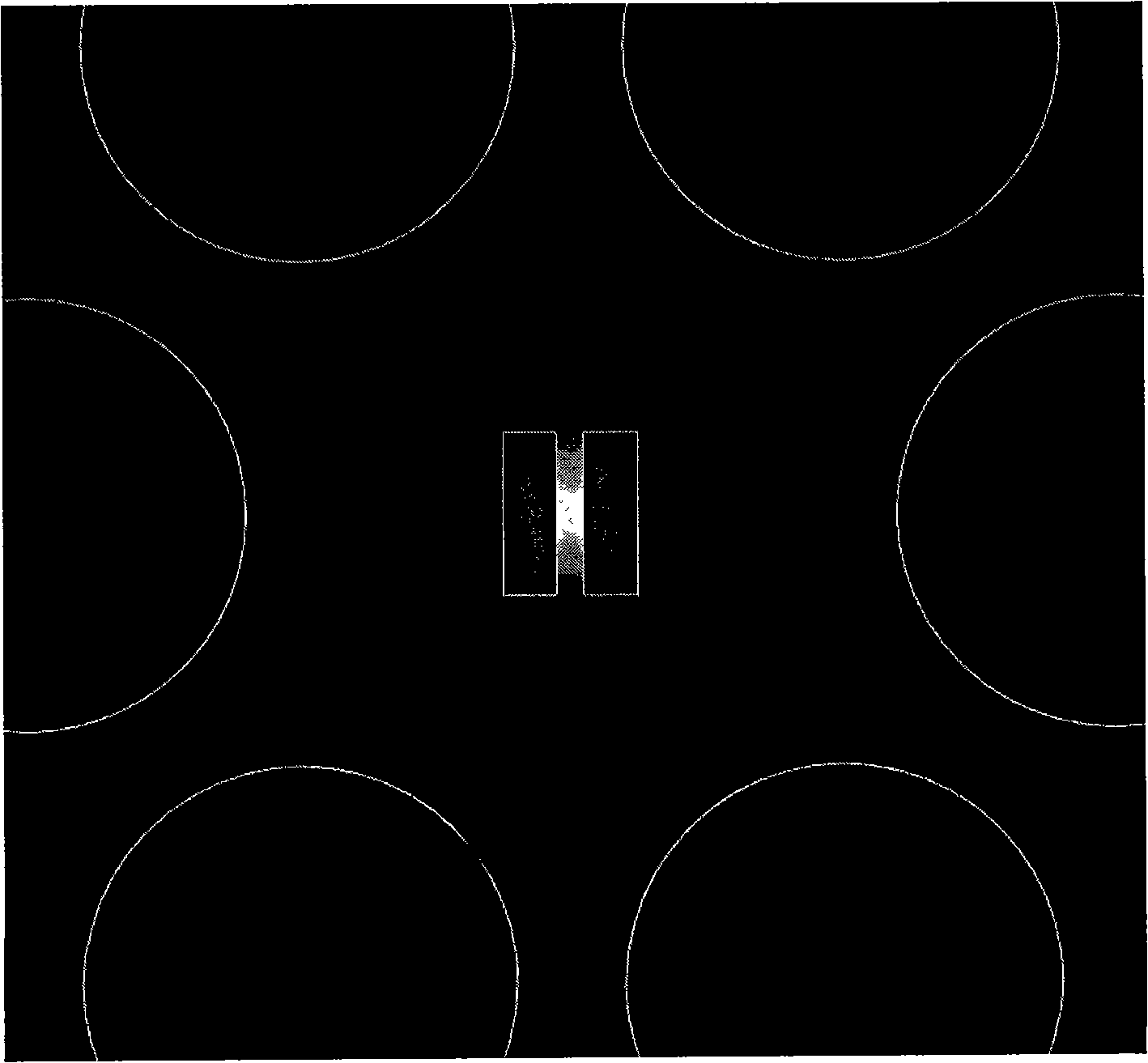

[0021] Refer to attached Figure 1~2 , a photonic crystal fiber based on the slit effect, with a cross-sectional structure such as figure 1 As shown, the base material 1 of the optical fiber is quartz, the refractive index at 1.55 μm is 1.45, and the nonlinear coefficient n 2 =2.6x10 -20 m 2 / W, the air holes 3 in the cladding are uniformly arranged in the base material 1 according to the equilateral triangle rule generally adopted by common photonic crystal fibers recognized in the art, and the distance between adjacent air holes is Λ=2 μm, and each air hole in the cladding The diameter of the hole 3 is d=0.8Λ. The two high-refractive-index materials 2 that form the slit 4 in the fiber core area and the base material 1 are silicon, and the refractive index at 1.55 μm is 3.46. The cross-section of each piece of high refractive index material 2 is a rectangle, the length of its long side is a=0.3Λ, the length of short side is b=0.1Λ, and the distance between the centers of ...

Embodiment 2

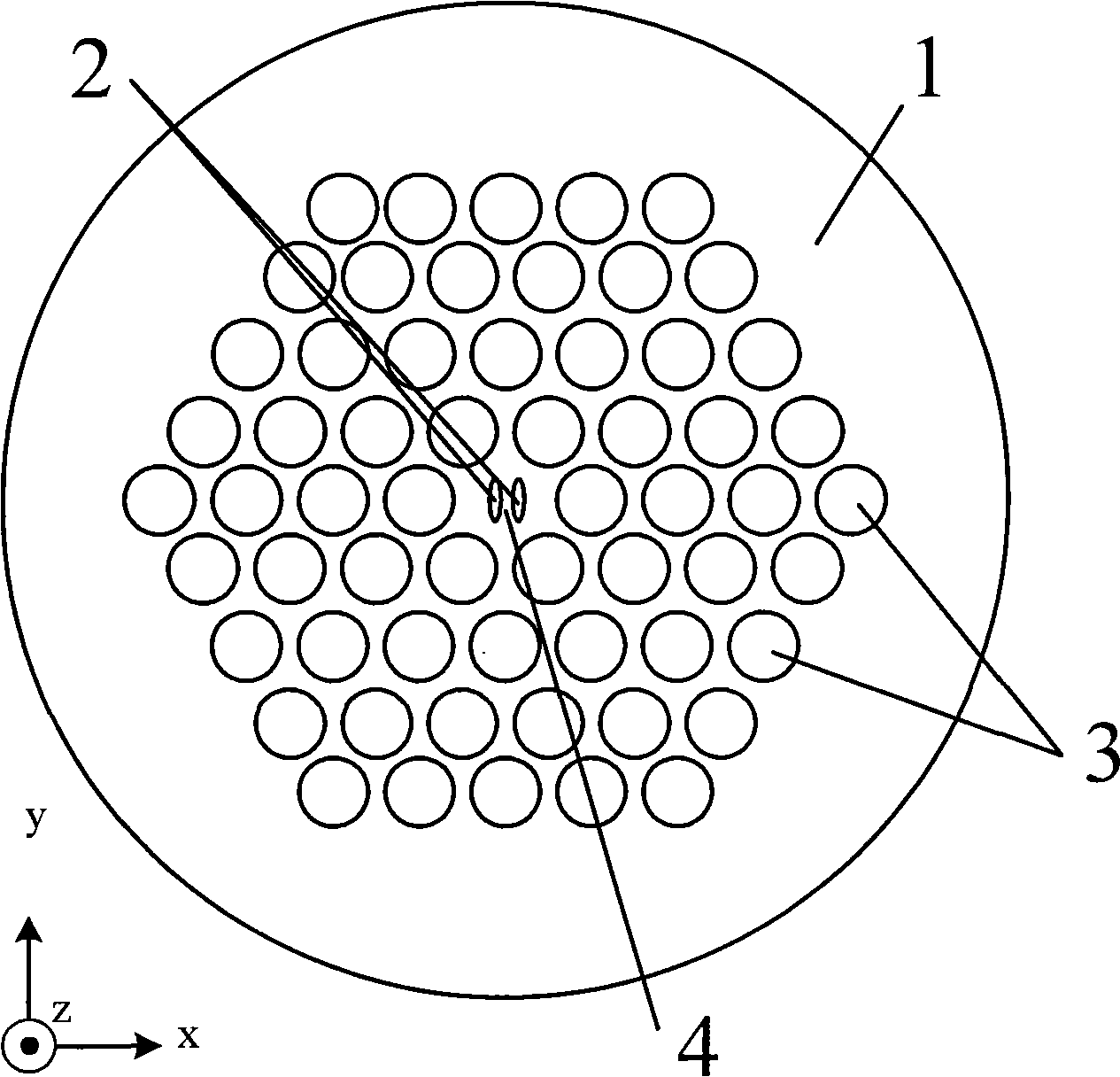

[0023] Refer to attached Figure 3-4 , another photonic crystal fiber based on the slit effect, with a cross-sectional structure such as image 3 As shown, the substrate material 1 of the optical fiber is highly nonlinear silicate glass Schott SF57, the refractive index at 1.55 μm is 1.8, and the nonlinear coefficient n 2 =4.1x10 -19 m 2 / W, the air holes 3 in the cladding are uniformly arranged in the base material 1 according to the equilateral triangle rule generally adopted by common photonic crystal fibers recognized in the art, and the distance between adjacent air holes is Λ=2 μm, and each air hole in the cladding The diameter of the hole 3 is d=0.8Λ. The two high-refractive-index materials 2 that form the slit 4 in the fiber core area and the base material 1 are silicon, and the refractive index at 1.55 μm is 3.46. The cross section of each piece of high refractive index material 2 is elliptical, its long axis is a=0.3Λ, its short axis is b=0.1Λ, and the distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com