Bristle automatic hair wrapping machine

An automatic, bristle technology, applied in the direction of bristles, winding mechanisms, mechanical processing, etc., can solve the problems of low bristle finishing efficiency, harsh labor environment, high labor intensity, etc. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

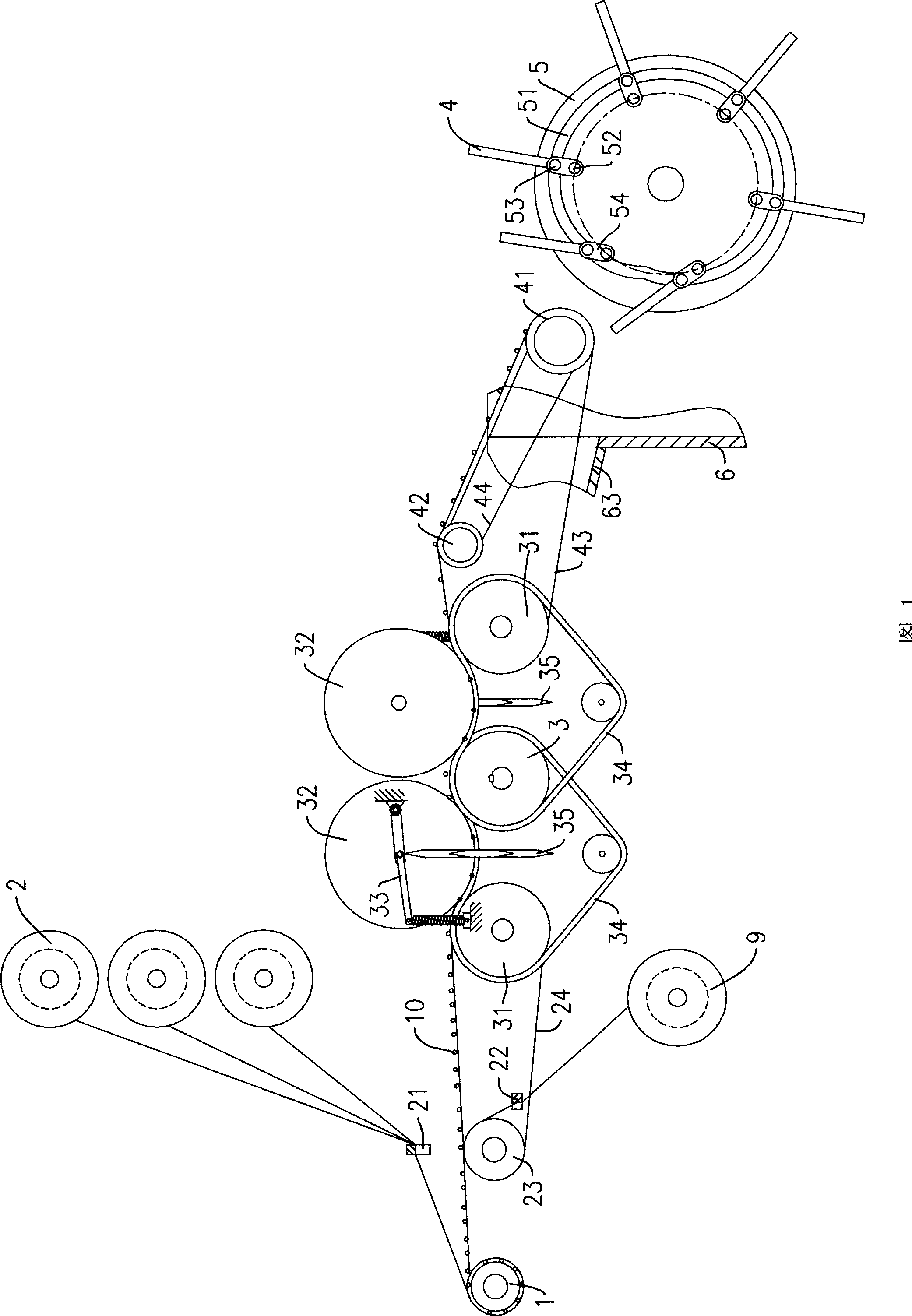

[0025] Such as figure 1 As shown, the boar bristle automatic wrapping machine includes a power unit, a hair picking device for picking out the wetted bristles 10, and a bristle for combing the bristles 10 picked out by the hair picking device. A hair combing device and a bristle winding device for clamping the combed bristles 10 by clamping wires and then winding them.

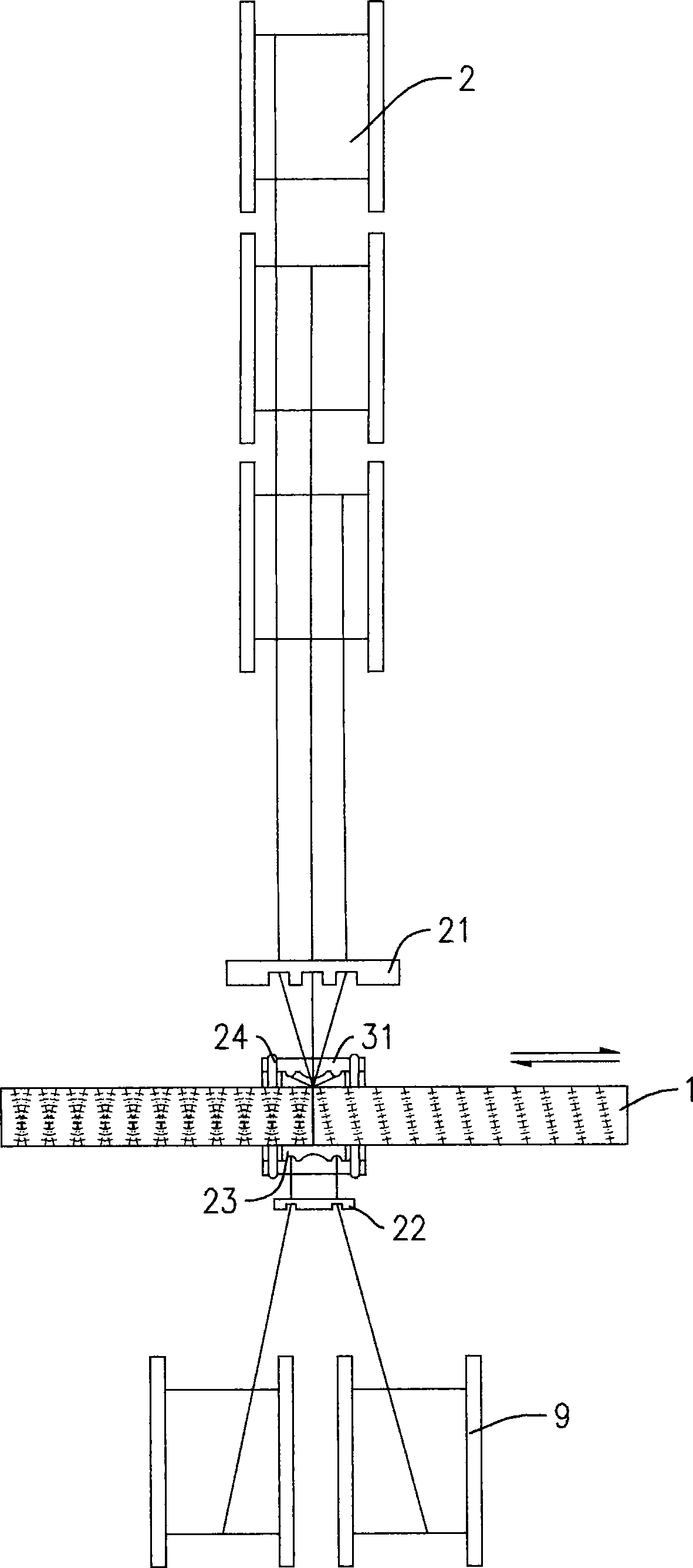

[0026] Such as figure 2 As shown, wherein the mane winding device includes a body with a hair winding roller 1, the hair winding roller 1 rotates under the drive of the power device and moves back and forth along its own axis direction, and the mane 10 combed by the mane carding device is formed by The clamping wire is clamped and introduced to be wound on the wrapping roller 1 .

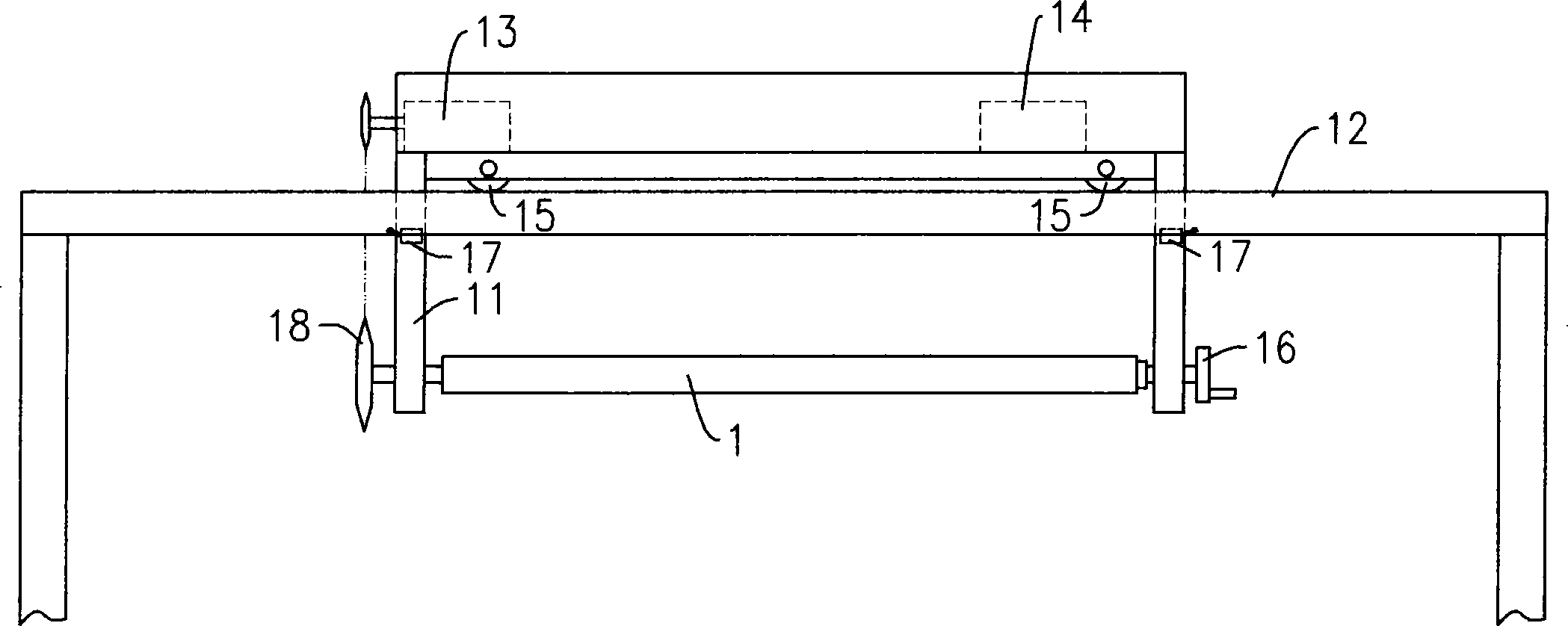

[0027] Such as image 3 As shown, the realization of the reciprocating movement of the wrapping roller 1 along its own axial direction while rotating on its own axis can be achieved by providing a guide rail 12 on the body, on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com