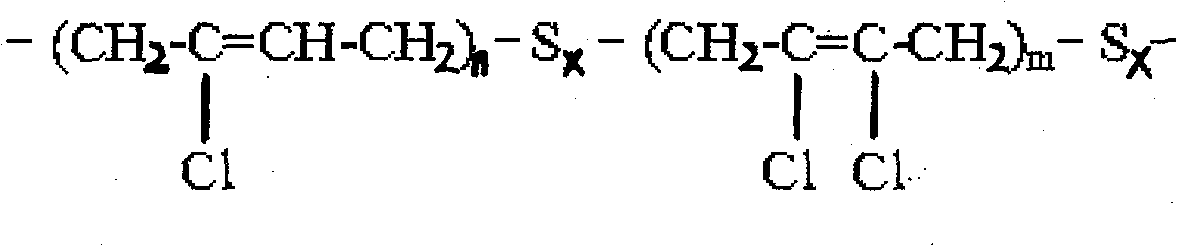

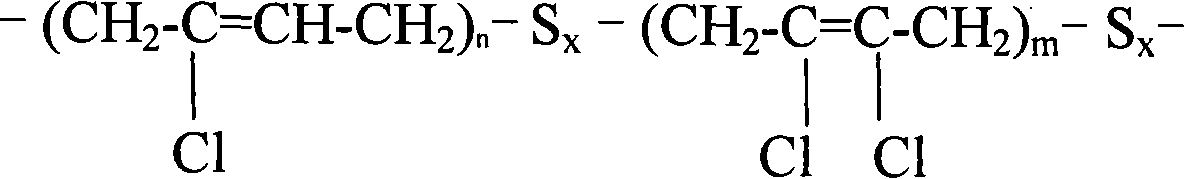

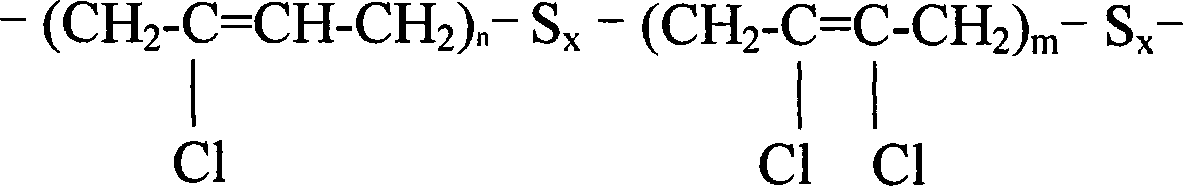

Sulfur-modified neoprene, method for preparing same and applications

A neoprene and sulfur-adjusted technology, which is applied in the direction of mechanical equipment, transmission belts, V-shaped belts, etc., can solve the problems of poor flexure crack resistance, poor Mooney viscosity stability, low tensile strength, etc., and achieve good mechanical properties and processing performance, improving the structure and composition, and improving the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: a kind of sulfur adjustment type chloroprene rubber, it is characterized in that it is the copolymer of chloroprene, 2,3-dichlorobutadiene and sulfur, each component distribution ratio and terminator in its polymerization reaction The group distribution ratio is shown in Table 5.

[0048] Each component distribution ratio (by weight) of polymerization reaction in the embodiment 1 of table 5

[0049]

[0050] The preparation method of above-mentioned sulfur adjustment type chloroprene rubber, it may further comprise the steps:

[0051] a, at first according to the proportioning of table 5, each component in the oil phase is chloroprene, 2,3-dichlorobutadiene, regulator sulfur and disproportionated rosin are mutually dissolved completely, and according to the proportioning of table 5, the water The components in the phase, that is, co-emulsifier sodium petroleum sulfonate and sodium lauryl sulfate, dispersant sodium alkylnaphthalene sulfonate, sodium hyd...

Embodiment 2

[0056] Example 2: A sulfur-adjusted chloroprene rubber, wherein the distribution ratio of each component in the polymerization reaction and the component distribution ratio of the terminator are shown in Table 6.

[0057] Each component distribution ratio (by weight) of the polymerization reaction in the embodiment 2 of table 6

[0058]

[0059] The preparation method of the above-mentioned sulfur-modified chloroprene rubber, wherein the polymerization reaction temperature is 20-25 ° C, and the rest are the same as in Example 1.

[0060] The weight-average molecular weight of the above-mentioned sulfur-adjusted chloroprene rubber is 107341, and the number-average molecular weight is 53538, which are determined by the same method and standard as in Example 1. In addition, the brittleness temperature measured by GB / T 15256-1994 low-temperature brittleness of vulcanized rubber is -40°C.

Embodiment 3

[0061] Embodiment 3: A sulfur-adjusted chloroprene rubber, wherein the distribution ratio of each component in the polymerization reaction and the component distribution ratio of the terminator are shown in Table 7.

[0062] Each component distribution ratio (by weight) of the polymerization reaction in the embodiment 3 of table 7

[0063]

[0064]

[0065] The preparation method of the above-mentioned sulfur-modified chloroprene rubber, wherein the polymerization reaction temperature is 25-30° C., and the rest are the same as in Example 1.

[0066] The weight-average molecular weight of the above-mentioned sulfur-adjusted chloroprene rubber is 136258, and the number-average molecular weight is 62849, which are determined by the same method and standard as in Example 1. In addition, according to GB / T 15256-1994 measurement standard of low-temperature brittleness of vulcanized rubber, the brittleness temperature is -41°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com