High molecular phosphoric acid ester, preparation method and uses thereof

A phosphate ester and polymer technology, which is applied in the field of antistatic modification of polymer materials and acid alcohol amide polyether polymer phosphate esters, can solve the problems of unsatisfactory compatibility of polymer materials and achieve good antistatic heat The effects of stable performance, excellent antistatic performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

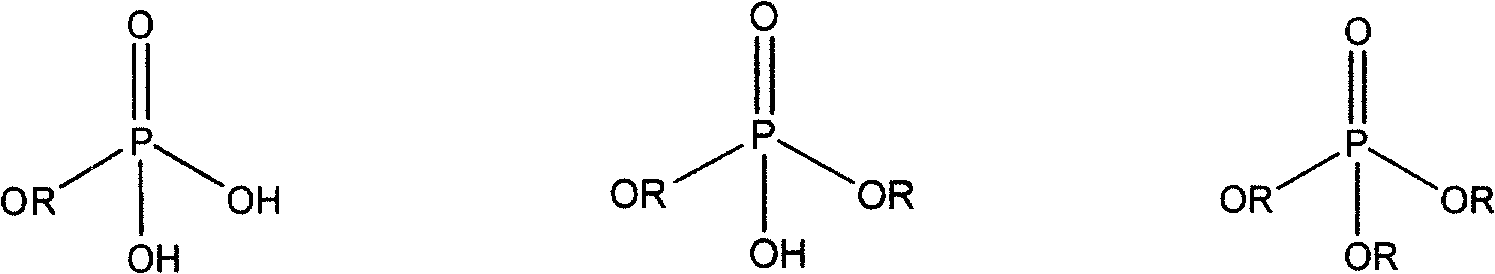

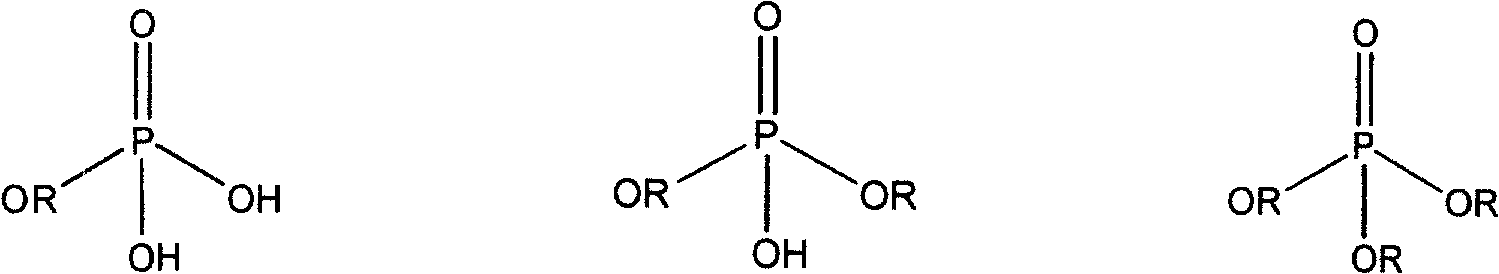

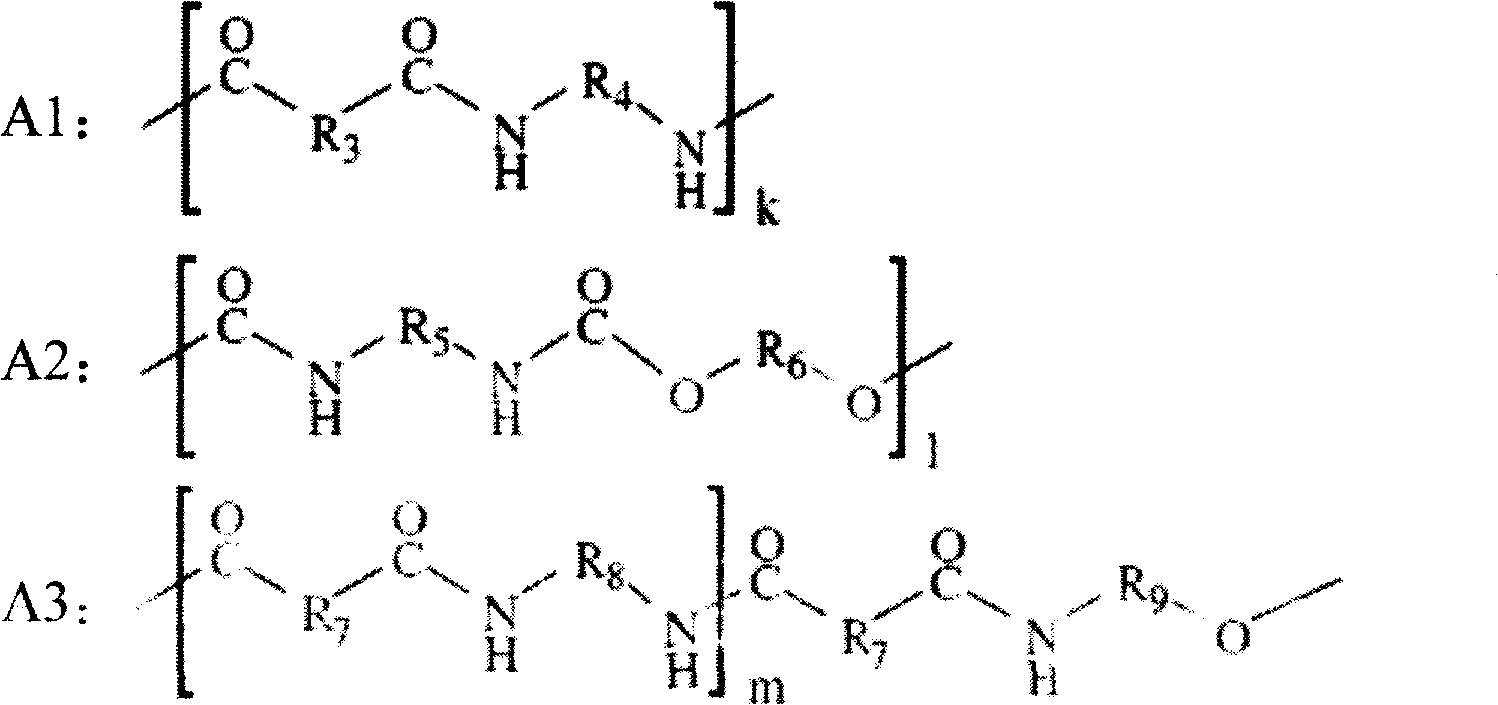

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Polymer Phosphate Synthesis (1)

[0037] ① The ratio of succinic acid, ethylenediamine and ethanolamine is 5.5:5:0.8 by substance. First add adipic acid and ethylenediamine into a three-necked flask with a Y-shaped liquid addition tube and a water separator, protect it with nitrogen, and condense to a certain molecular weight at 145°C, then add 0.5% NaOH, drop 3 / 4 ethanolamine, reacted for 4 hours. Afterwards, drop the remaining ethanolamine and react at 105°C for 3 hours to prepare acid alcohol amide. According to GB / T15046-94, the amine value <25mg KOH / g is qualified.

[0038] ②The weight ratio of acid alcohol amide and toluene diisocyanate is 3.5:1. First add the acid alcohol amide to the three-necked flask, slowly add toluene diisocyanate dropwise with a dropping funnel, react at 60°C for 2 hours, then raise the temperature to 80°C, add polyether 800 twice the amount of toluene diisocyanate, and react 3 Hour. Then, slowly add POCl of 1 / 2 times the amo...

Embodiment 2

[0039] Embodiment 2: Polymer phosphate synthesis (two)

[0040] ① Adipic acid, ethylenediamine and ethanolamine are in a ratio of 5.5:5:0.8 by substance. First add adipic acid and ethylenediamine to a three-necked flask with a Y-shaped liquid pipe and a water separator, protect it with nitrogen, and condense to a certain molecular weight at 165°C, then add 0.5% NaOH, drop 3 / 4 ethanolamine, reacted for 4 hours. Afterwards, drop the remaining ethanolamine and react at 105°C for 3 hours to prepare acid alcohol amide. According to GB / T15046-94, the amine value <25mg KOH / g is qualified.

[0041] ② The weight ratio of acid alcohol amide, epichlorohydrin and boron trifluoride ether is 4:1:0.03. First add acid alcohol amide and boron trifluoride ethyl ether into a three-necked flask, slowly add epichlorohydrin dropwise with a dropping funnel, react at 90°C for 6 hours and then cool down to 60°C, add the same amount of substances as epichlorohydrin 40% NaOH solution, reacted for 2 h...

Embodiment 3

[0043] Embodiment 3: Polymer phosphate synthesis (three)

[0044] ①The molar ratio of octadecanoic acid and ethanolamine is 1:1. First, octadecanoic acid was added to a three-necked flask with a Y-shaped liquid pipe and a water separator, 0.01%-3.0% NaOH was added, 3 / 4 ethanolamine was added dropwise, and the reaction was carried out at 170°C for 4 hours. Afterwards, drop the remaining ethanolamine and react at 100°C for 3 hours to produce acid alcohol amide. According to GB / T15046-94, the amine value <20mg KOH / g is qualified.

[0045] ② The weight ratio of acid alcohol amide, epichlorohydrin and boron trifluoride ether is 3:1:0.03. First add acid alcohol amide and boron trifluoride ethyl ether into the three-necked bottle, slowly add epichlorohydrin dropwise with a dropping funnel, react at 90°C for 6 hours, cool down to 60°C, and add the amount of the substance that is mixed with epichlorohydrin The same 40% NaOH solution was reacted for 2 hours, filtered and distilled und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com