Biomass fuel gas gas-making method by dry method

A technology of biomass gas and biomass materials, which is applied in the direction of biofuel, special dry distillation, petroleum industry, etc., can solve the problems of reducing purification efficiency, clogging the stove hole, and small gap between fan blades, achieving beautiful appearance and lightening The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present invention it comprises the steps:

[0055] 1. Preparation

[0056] Use bulk biomass materials;

[0057] 2. Feeding

[0058] Biomass materials are added to the biomass gas gas furnace;

[0059] 3. Gas production

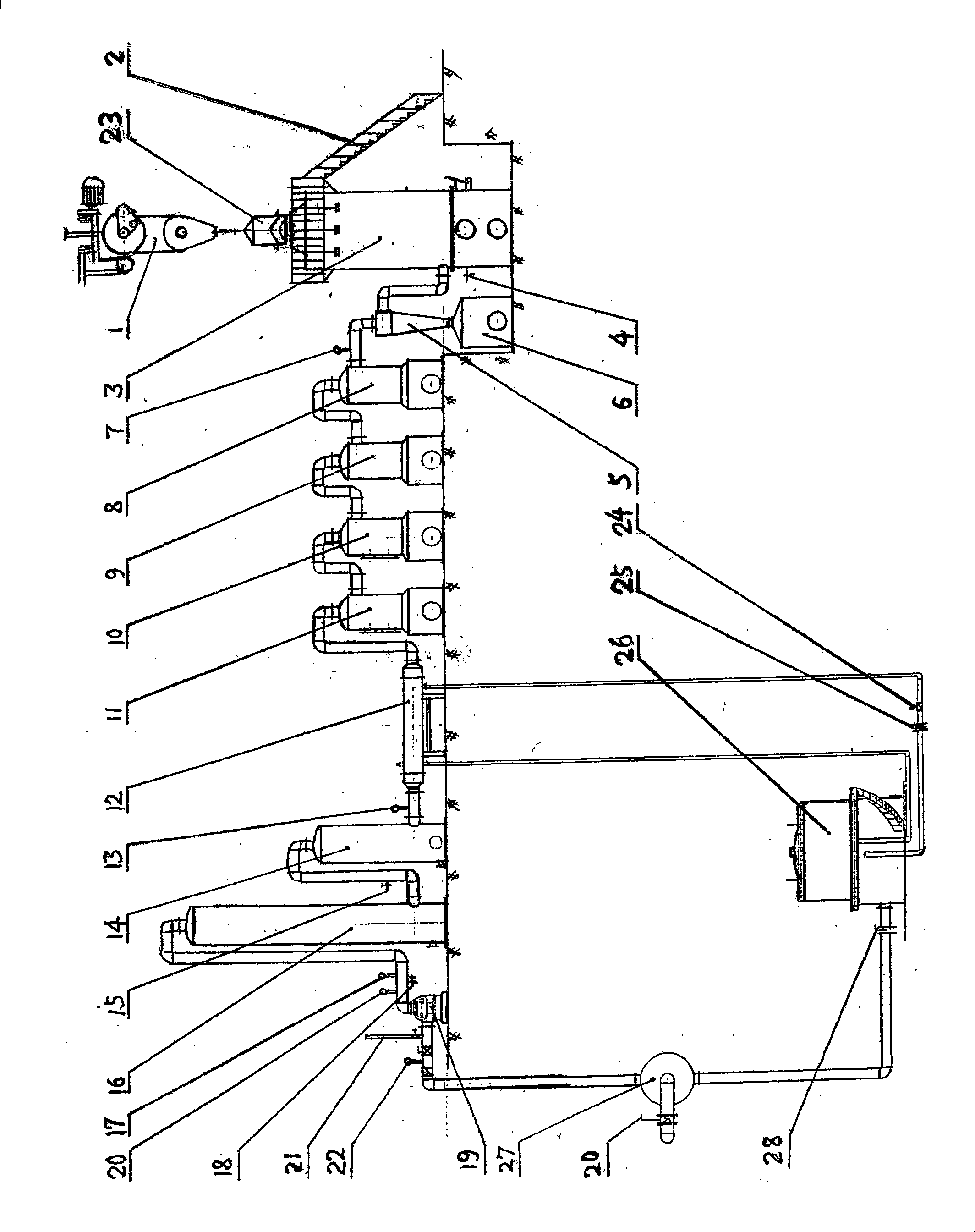

[0060] The gas-making raw materials are added to the biomass gas gas-making furnace and undergo thermal reaction to generate mixed gas, which enters the dust removal system through the gas outlet (11);

[0061] 4. Dust removal

[0062] Under the action of cyclone dust removal, 50% of the ash in the mixed gas is removed to obtain gas, and the removed ash enters the ash storage box (6);

[0063] The gas continues to be purified through the purification tower to obtain finished gas;

[0064] 5. Heat exchange

[0065] The finished gas enters the condenser (12) for heat exchange so that the gas temperature at the outlet of the condenser (12) is 35°C; the condensed water, tar and clean finished gas enter the gas-liquid separation tower (14); label ...

Embodiment 2

[0074] The present invention it comprises the steps:

[0075] 1. Preparation

[0076] Use bulk biomass materials;

[0077] 2. Feeding

[0078] Biomass materials are added to the biomass gas gas furnace;

[0079] 3. Gas production

[0080] The gas-making raw materials are added to the biomass gas gas-making furnace and undergo thermal reaction to generate mixed gas, which enters the dust removal system through the gas outlet (11);

[0081] 4. Dust removal

[0082] Under the effect of cyclone dust removal, 60% of the ash in the mixed gas is removed to obtain gas, and the removed ash enters the ash storage box (6);

[0083] The gas continues to be purified through the purification tower to obtain finished gas;

[0084] 5. Heat exchange

[0085] The finished gas enters the condenser (12) for heat exchange so that the outlet gas temperature of the condenser (12) is 38°C; the condensed water, tar and clean finished gas enter the gas-liquid separation tower (14);

[0086] 6. ...

Embodiment 3

[0094] The present invention comprises the steps:

[0095] 1. Preparation

[0096] Use bulk biomass materials;

[0097] 2. Feeding

[0098] Biomass materials are added to the biomass gas gas furnace;

[0099] 3. Gas production

[0100] The gas-making raw materials are added to the biomass gas gas-making furnace and undergo thermal reaction to generate mixed gas, which enters the dust removal system through the gas outlet (11);

[0101] 4. Dust removal

[0102] Under the action of cyclone dust removal, 70% of the ash in the mixed gas is removed to obtain gas, and the removed ash enters the ash storage box (6);

[0103] The gas continues to be purified through the purification tower to obtain finished gas;

[0104] 5. Heat exchange

[0105] The finished gas enters the condenser (12) for heat exchange so that the gas temperature at the outlet of the condenser (12) is 40°C; the condensed water, tar and clean finished gas enter the gas-liquid separation tower (14);

[0106]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com