Heat barrier coatings damage and its failure procedure acoustic emission real-time detection method

A technology of thermal barrier coating and real-time detection, which is applied in the processing of detection response signals and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., and can solve the problems of no reported research progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

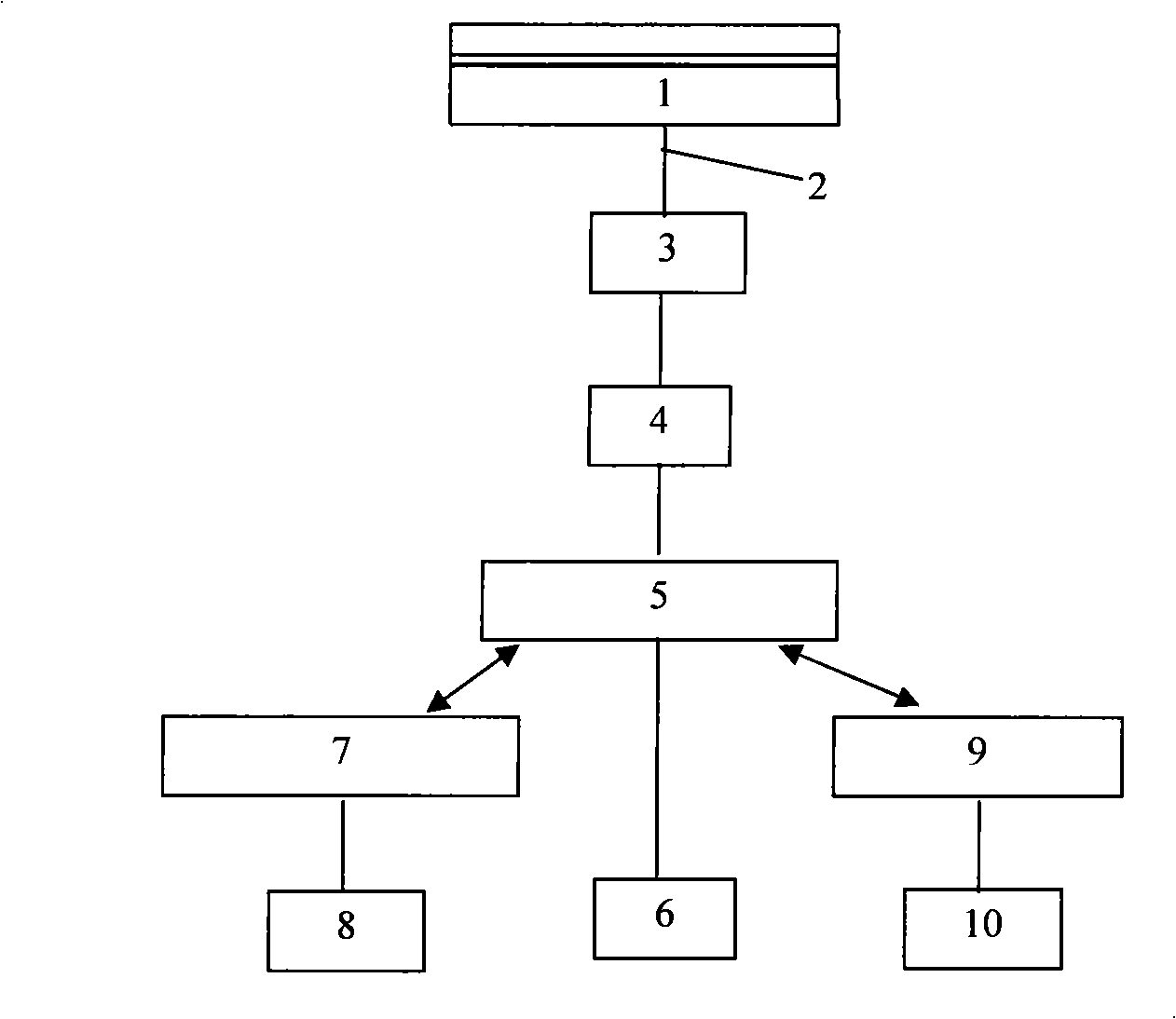

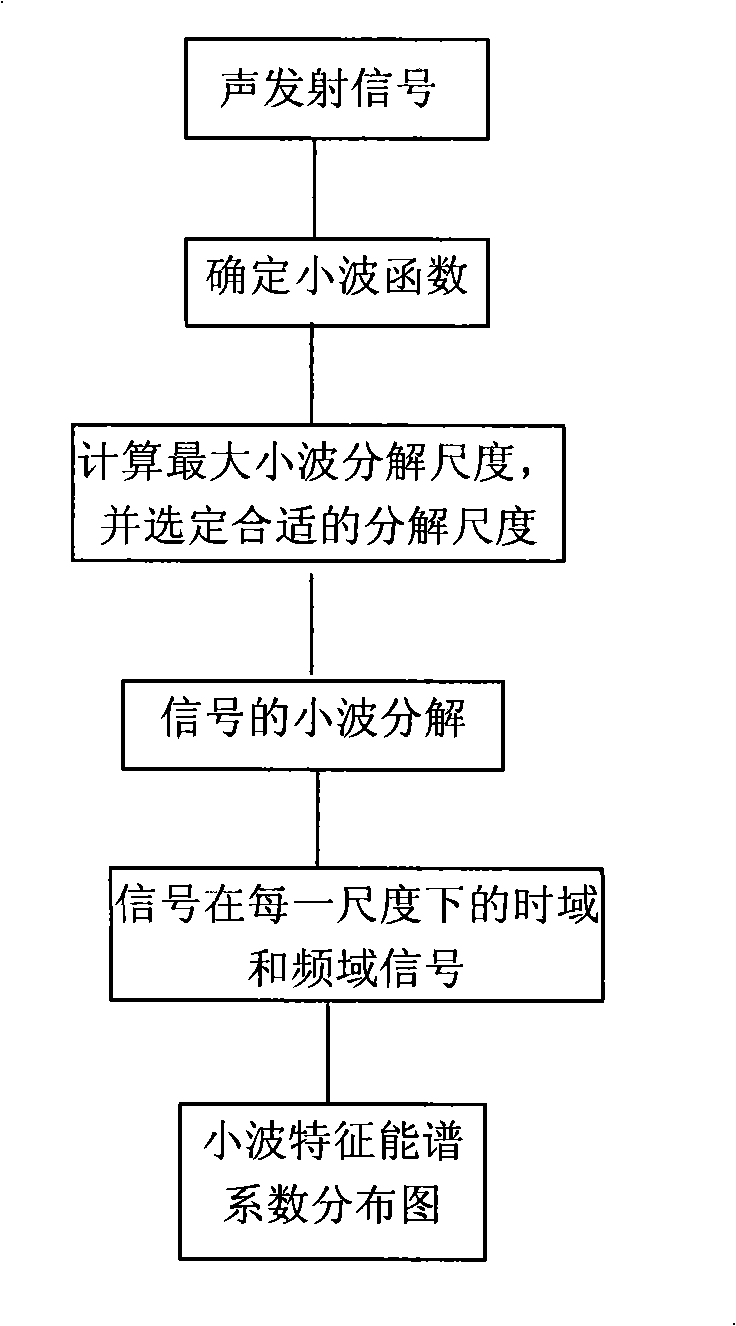

Method used

Image

Examples

specific Embodiment 1

[0074] Acoustic emission real-time detection of tensile failure process of thermal barrier coatings at room temperature. The base material of the plasma sprayed thermal barrier coating sample is GH3030, and the intermediate transition layer material is NiCr 22 al 7 Y 0.2 (wt.%), the ceramic layer material is ZrO 2 -8wt.%Y 2 o 3 , the thicknesses of the intermediate transition layer and the ceramic layer are both about 200 μm. The experiment uses a universal tensile machine to load the sample. At the same time, two acoustic emission sensors are placed at both ends of the sample to receive the acoustic emission signal and collect it by the acoustic emission instrument. The sampling frequency is 1MHz, the sampling length is 1K, and the threshold is set 36dB. Tensile and acoustic emission tests were carried out on the uncoated base material and the thermal barrier coating, respectively.

[0075] During the tensile failure process, the distribution of acoustic emis...

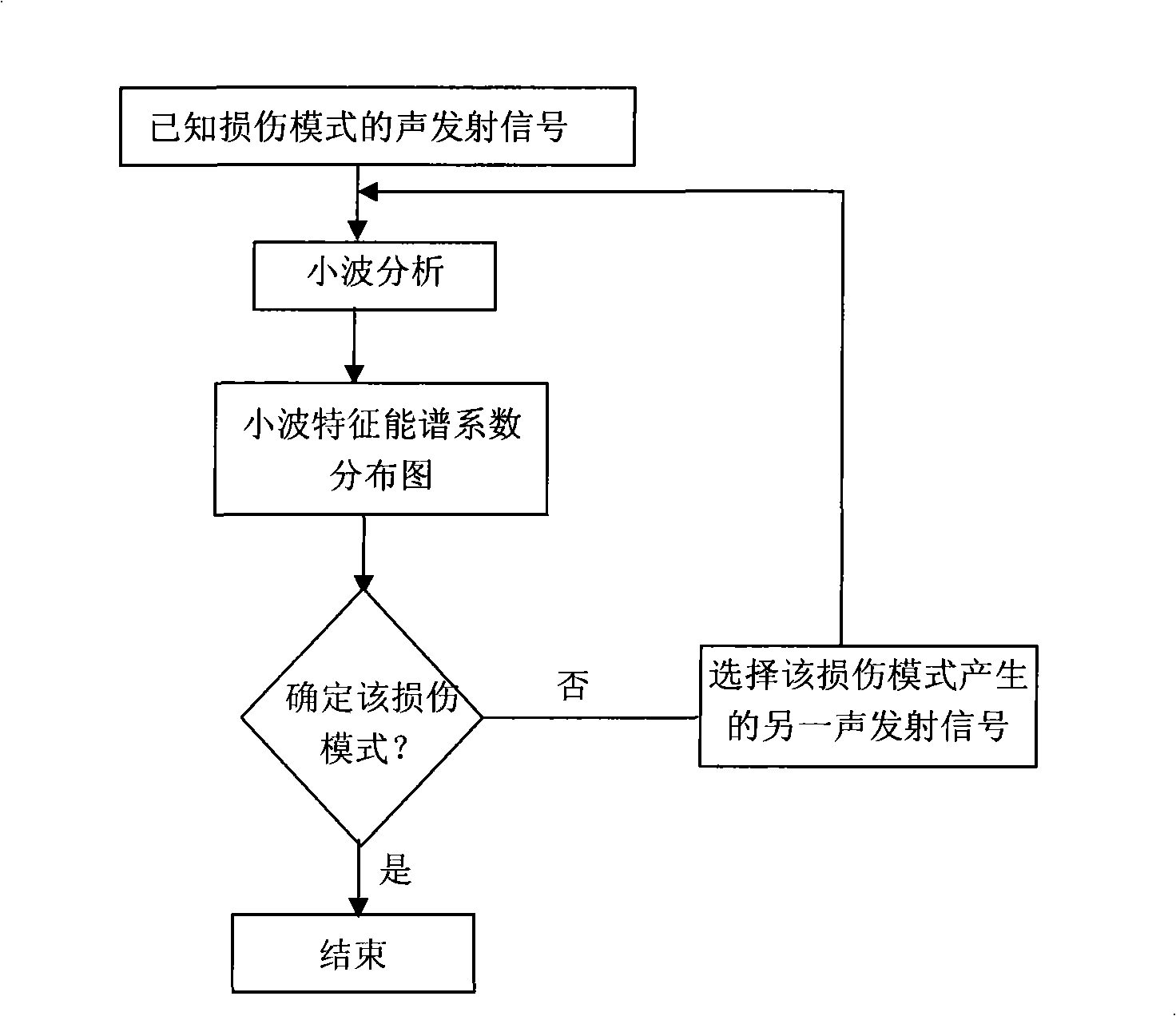

specific Embodiment 2

[0080] Acoustic emission real-time detection of high temperature thermal fatigue failure of thermal barrier coatings. Acoustic emission detection experiment of high temperature thermal cycle was carried out on the thermal barrier coating. The thermal cycle included two processes of heating in a high temperature furnace at 800°C for 5 minutes and natural cooling in air for 10 minutes. In the experiment, the substrate surface of the thermal barrier coating sample was spot-welded with a platinum wire waveguide, and connected to the acoustic emission sensor through a mechanical device and an acoustic coupling medium to detect the damage of the thermal barrier coating during the entire thermal cycle.

[0081] The acoustic emission test results of thermal barrier coatings in the whole thermal fatigue found that the acoustic emission signal can appear in both the cooling stage and the heating stage, such as Figure 12 As shown, this shows that the damage of thermal barrier coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com