Nonmetal filling medium for producing piping branch junctions and technique for squeezing the piping branch junctions

A technology of filling medium and manufacturing process, applied in metal extrusion forming tools, metal extrusion, manufacturing tools, etc., can solve the problems of lead pollution, high production cost, slow work efficiency, etc., achieve obvious technical advantages, avoid pollution, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

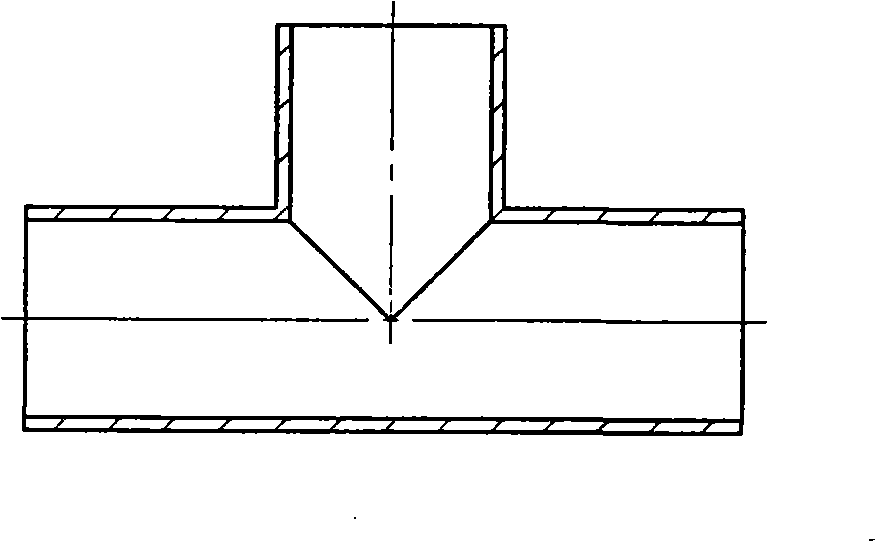

[0026] See attached figure 1 As shown, the main manufacturing process of T-shaped pipes (such as: outer diameter φ25.4) is: blanking → straight-through pipe filling with powder medium → cold extrusion → removing the filled powder medium → pickling → drying → packaging; Its non-metallic filling powder medium is composed of talc powder H 2 Mg 3 (sio 3 ) 4 and industrial salt NaCl two powders, which can be uniformly mixed according to the mass ratio of 25% and 75% respectively.

Embodiment 2

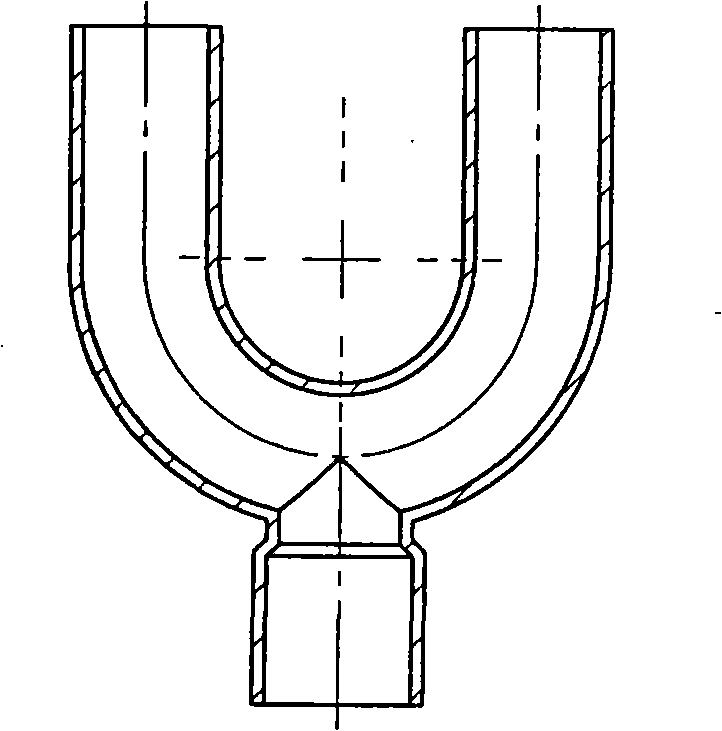

[0028] See attached Figure 4 As shown, the main manufacturing process of the trident tube (such as: outer diameter φ7) is: blanking→straight-through tube filling with powder medium→cold extrusion→annealing→mechanical forming→removing the filled powder medium→pickling→drying→ Packaging; its non-metallic filled powder medium consists of talc H 2 Mg 3 (sio 3 ) 4 , industrial salt NaCl and urea (NH 2 ) 2 The three powders of CO are composed of three kinds of powders, and they are uniformly mixed according to the mass ratio of 20%, 60% and 20%, respectively.

Embodiment 3

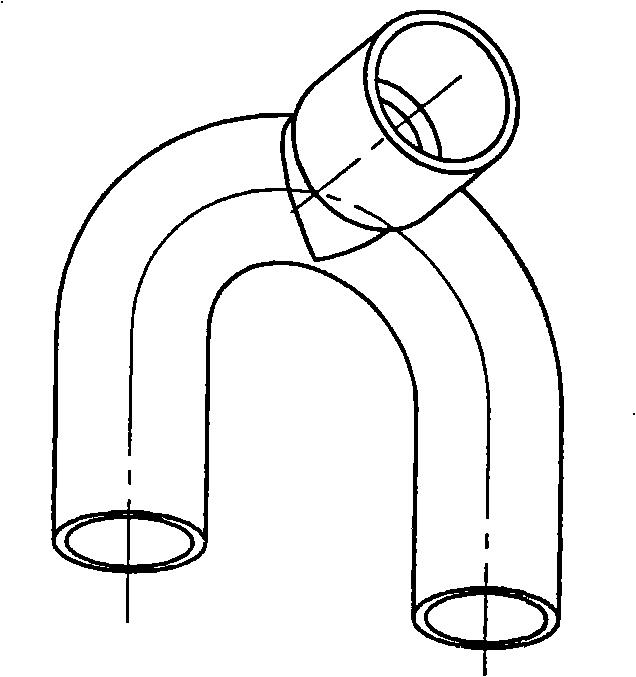

[0030] See attached Figure 6 As shown, the main manufacturing process of the four-way pipe (such as: outer diameter φ7.94) is: blanking → straight pipe filling with powder medium → cold extrusion → removing the filled powder medium → pickling → drying → packaging; Its non-metallic filling powder medium is composed of talc powder H 2 Mg 3 (sio 3 ) 4 It consists of two powders of industrial salt NaCl and can be uniformly mixed according to the mass ratio of 15% and 85% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com