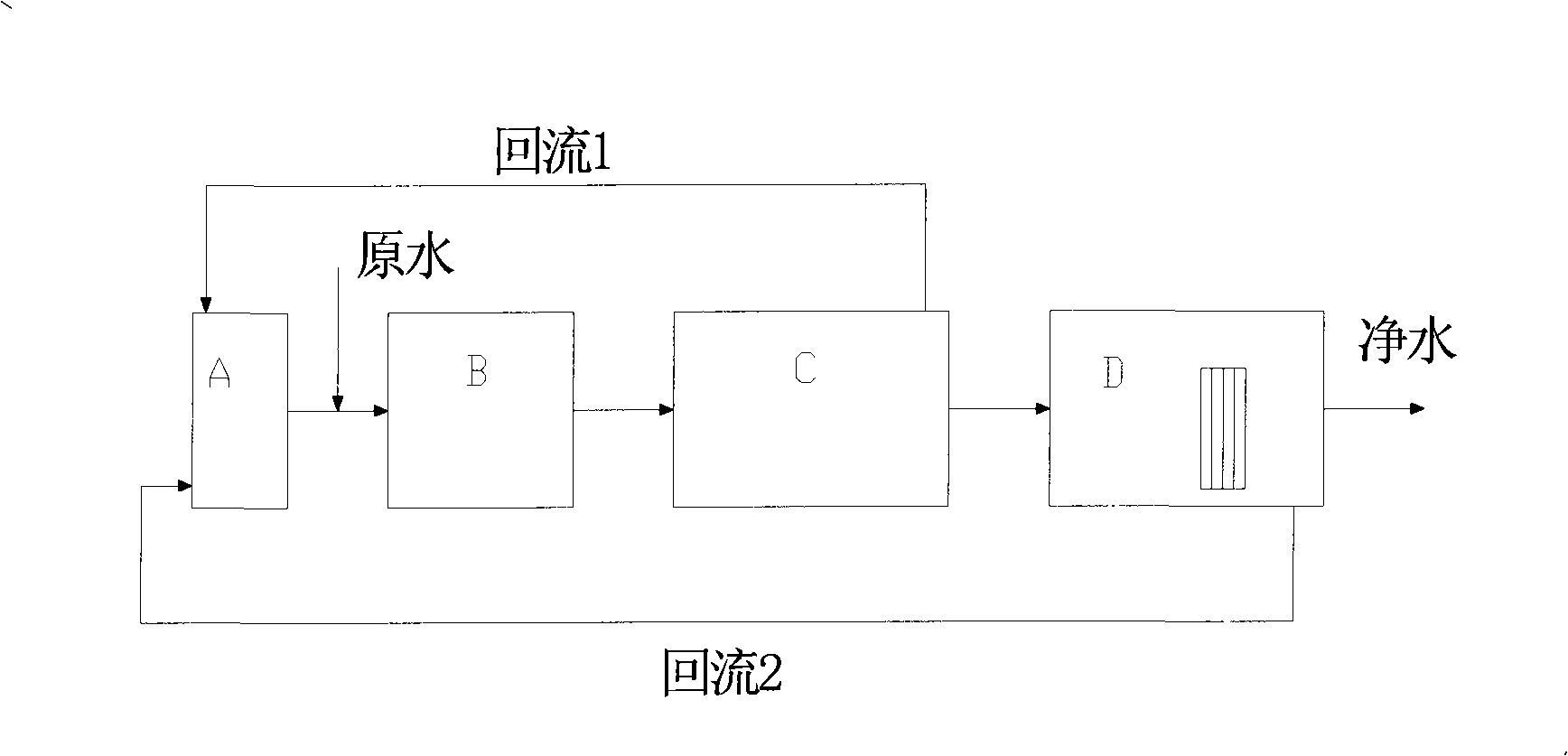

Membrane bioreactor effluent treatment process for increasing denitrification effect

A membrane bioreactor, sewage treatment technology, applied in the direction of sustainable biological treatment, aerobic and anaerobic process treatment, etc. problems, to achieve the effect of improving denitrification efficiency, saving water pumps, and reducing hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

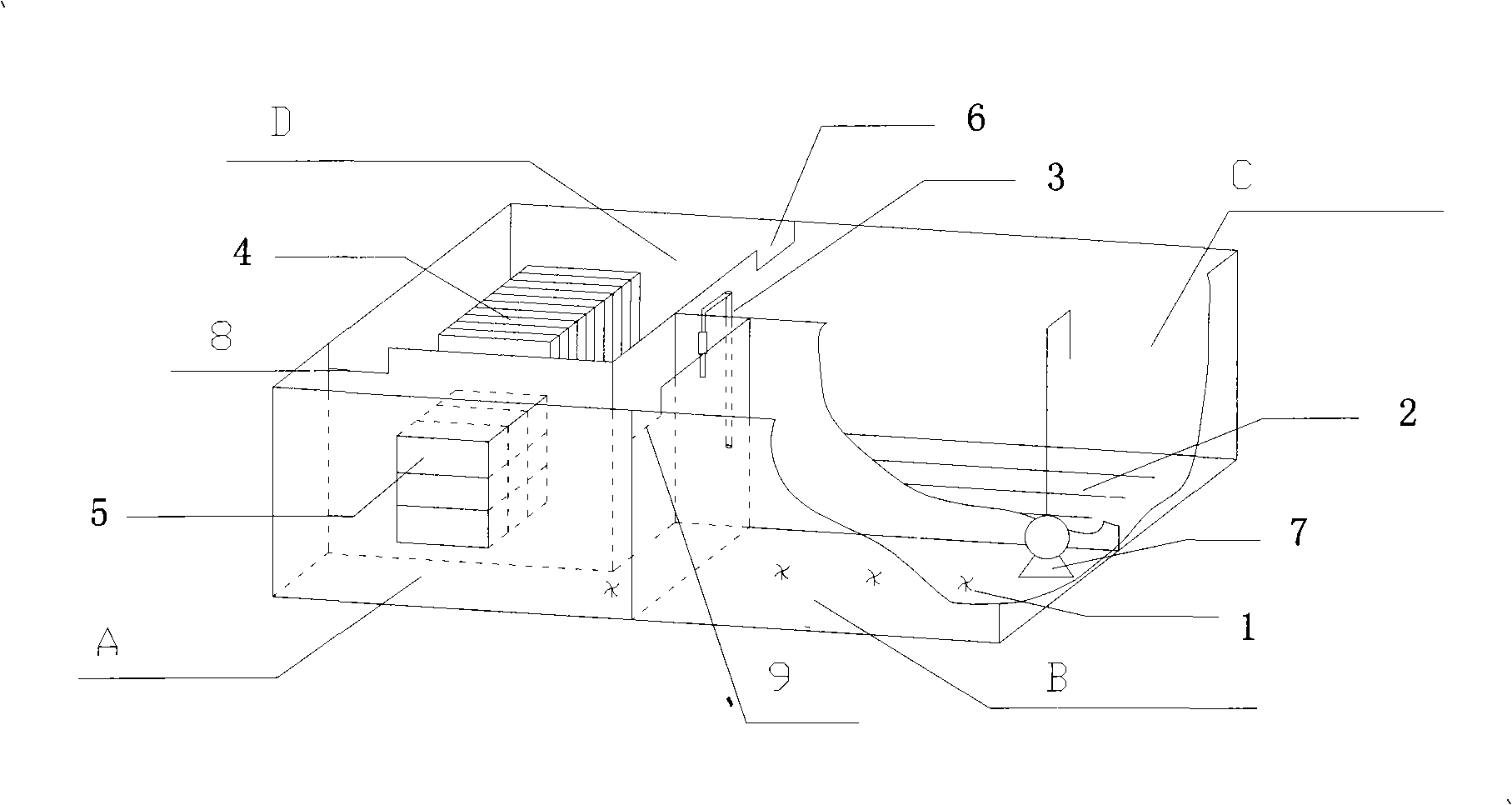

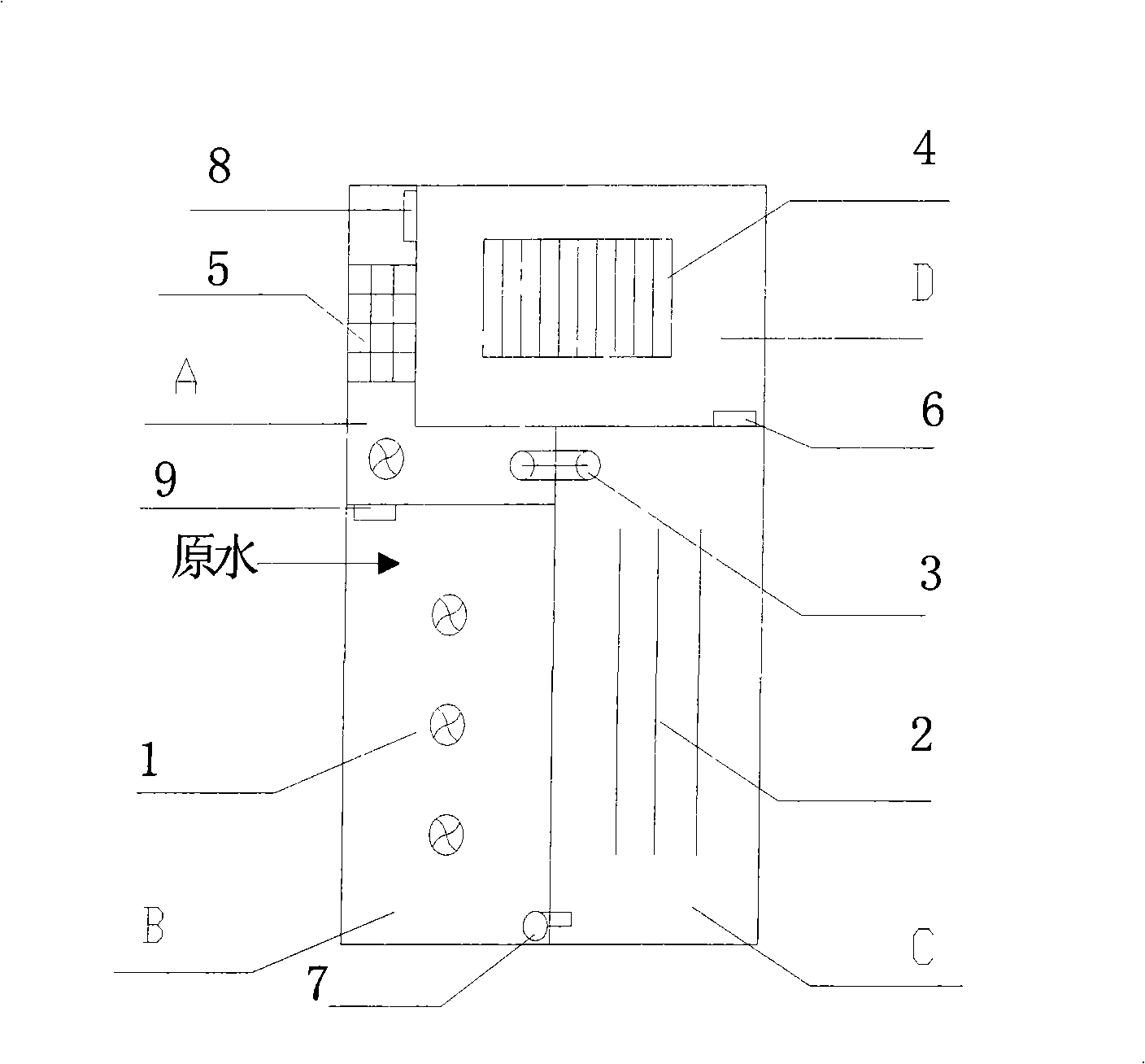

Embodiment 1

[0021] The raw water is municipal sewage, and the reactor sludge concentration is about 11000mg / L. Raw water enters the anoxic zone of the reactor, and the mixed solution in the anoxic zone is mixed evenly by stirring; The hydraulic retention time of the liquid is 4.5h, and the dissolved oxygen in the zone is maintained between 0.7mg / L-0.8mg / L through micro-aeration tube aeration; the mixed liquor in the synchronous nitrification and denitrification zone Part of it is sent through the first overflow port to the membrane zone of the reactor in which the membrane module is installed. A siphon with a flowmeter is returned to the facultative zone of the reactor, and the volume ratio of the reflux liquid to the purified water outlet in the membrane zone of the reactor is 200%; a part of the mixed solution in the membrane zone of the reactor is covered by the membrane After the component is filtered and purified, it is discharged, and part of it flows back into the facultative zone...

Embodiment 2

[0024]The raw water is municipal sewage, and the reactor sludge concentration is about 11000mg / L. Raw water enters the anoxic zone of the reactor, and the mixed solution in the anoxic zone is mixed evenly by stirring; The hydraulic retention time of the liquid is 4h, and the dissolved oxygen in the zone is kept between 0.8mg / L-1.0mg / L through micro-aeration tube aeration; The dissolved oxygen concentration in the membrane area is between 2.5mg / L-3.0mg / L, and the other part of the mixed liquid passes through the reactor with membrane modules through the first overflow port. The siphon of the flowmeter returns to the facultative zone of the reactor, and the volume ratio of the reflux liquid to the purified water effluent in the membrane zone of the reactor is 100%; Discharge after filtering and purifying, and part of it flows back into the facultative zone of the reactor through the second overflow port. A partition with a flow channel, then enters the anoxic zone through the ...

Embodiment 3

[0027] The raw water is municipal sewage, and the reactor sludge concentration is about 11000mg / L. Raw water enters the anoxic zone of the reactor, and the mixed solution in the anoxic zone is mixed evenly by stirring; The hydraulic retention time of the liquid is 5h, and the dissolved oxygen in the zone is maintained between 0.8mg / L-0.9mg / L through micro-aeration tube aeration; The dissolved oxygen concentration in the membrane area is between 2.5mg / L-3.0mg / L, and the other part of the mixed liquid passes through the reactor with membrane modules through the first overflow port. The siphon of the flowmeter returns to the facultative zone of the reactor, and the volume ratio of the reflux liquid to the purified water effluent in the membrane zone of the reactor is 300%; Discharge after filtering and purifying, and part of it flows back into the facultative zone of the reactor through the second overflow port, and the volume ratio of the reflux liquid and the purified water ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com