Electrical heating setting roller

A technology of heat setting and electric heating, which is applied in heating/cooling of fabrics, heat treatment of artificial filaments, textiles and papermaking, etc. It can solve problems such as damage to heat setting roller equipment, difficulty in timely control of heater heating temperature, and impact on safety production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

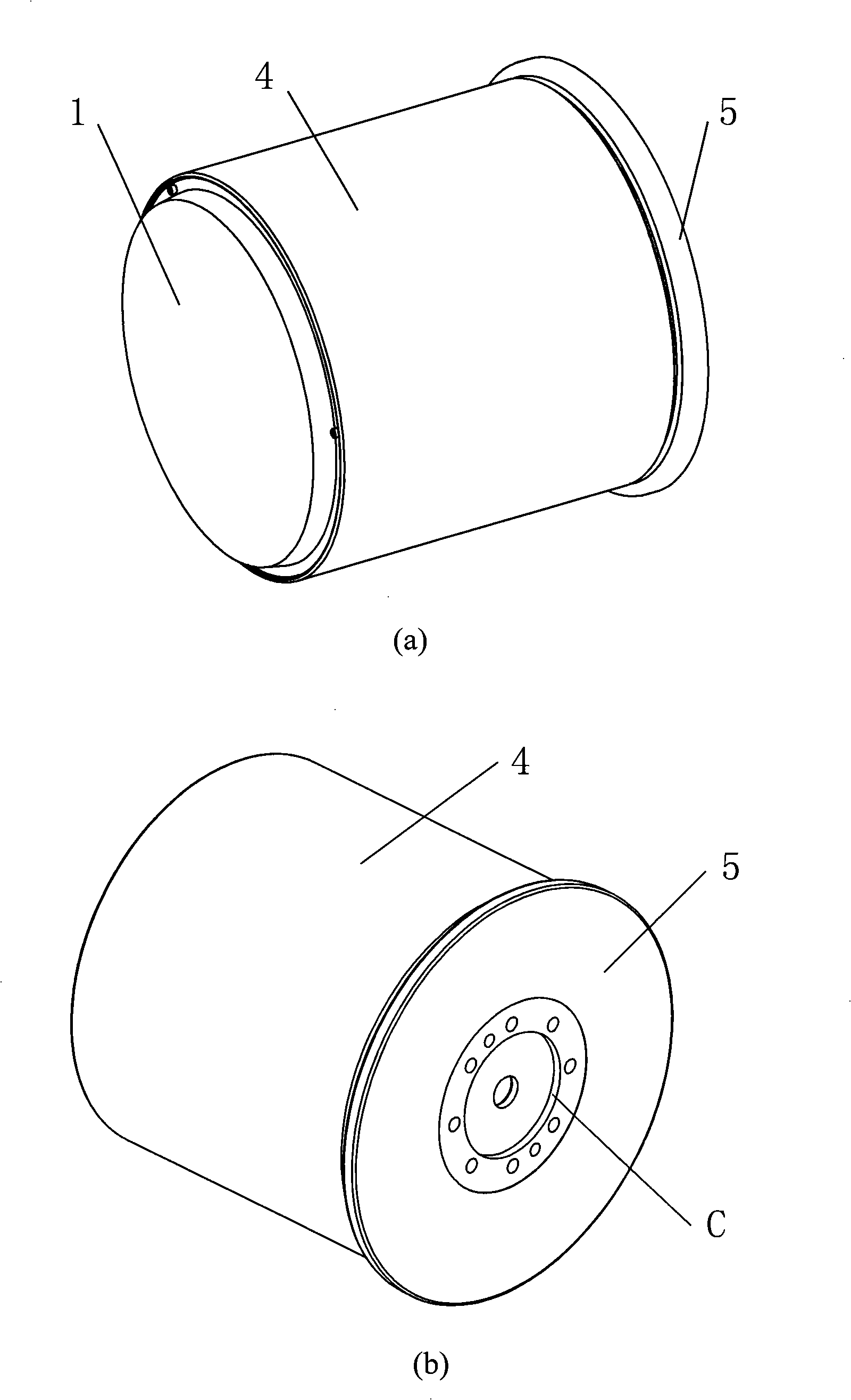

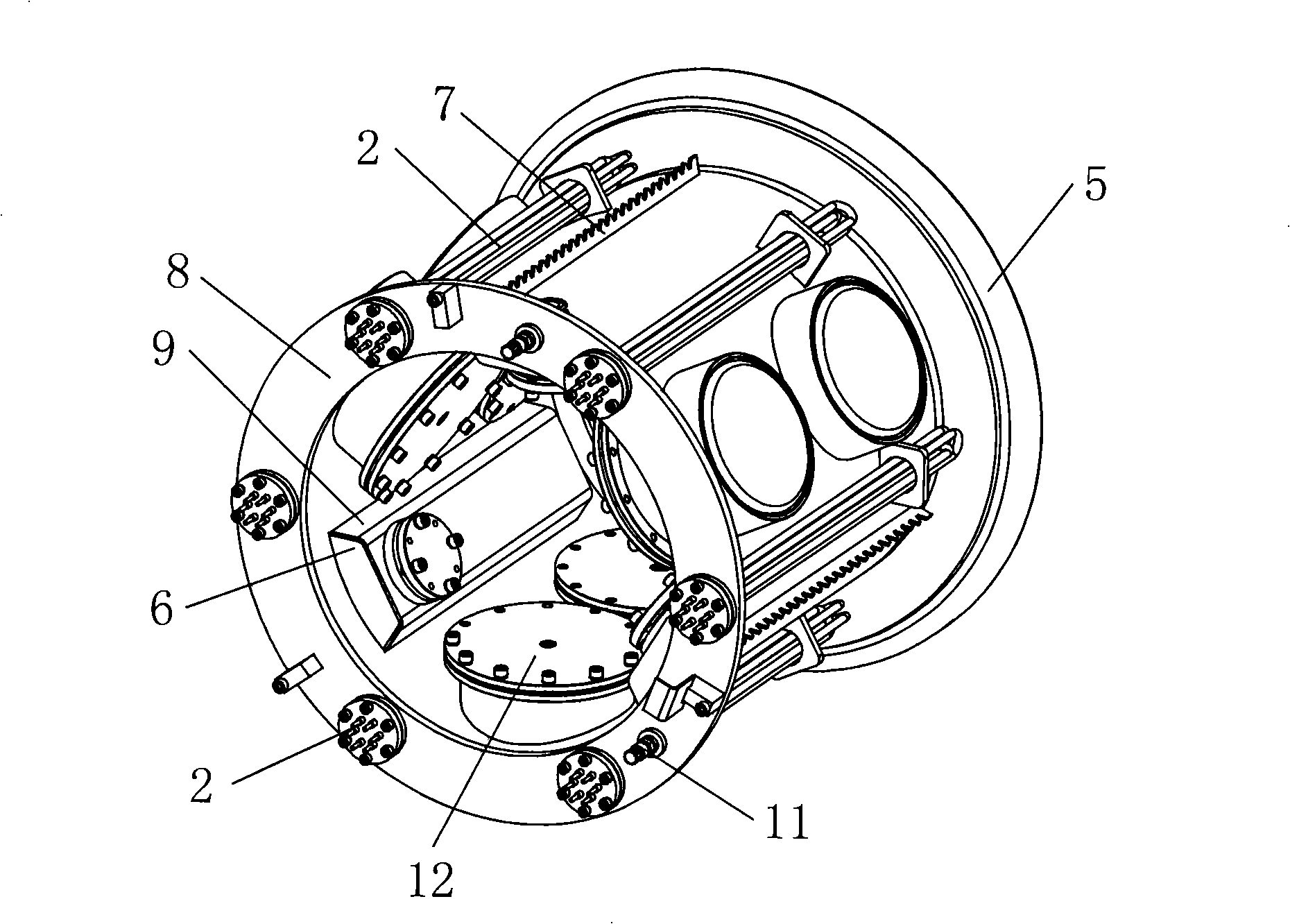

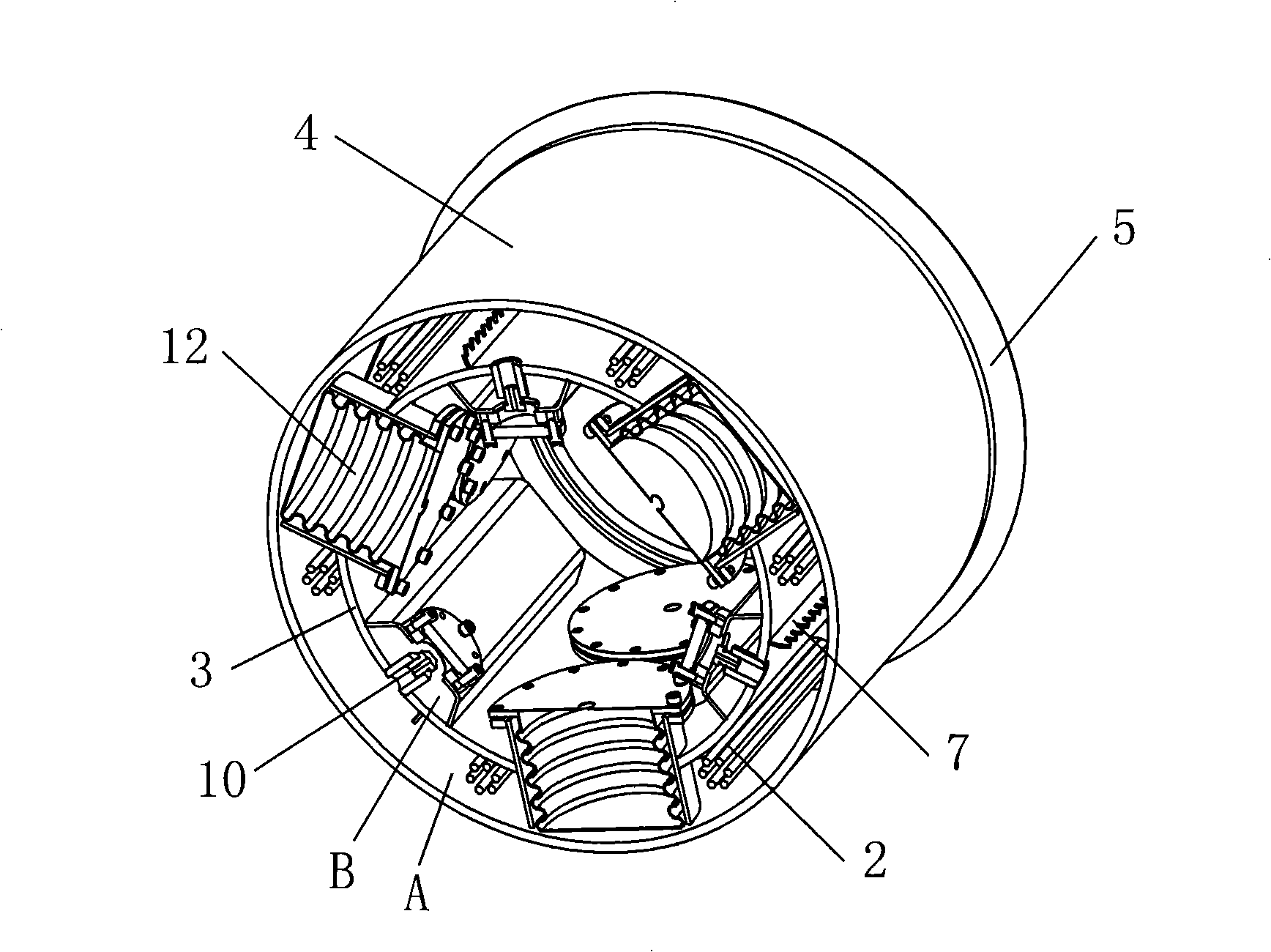

[0018] see figure 2 , image 3 and Figure 4 , an electric heating heat setting roller, including an outer jacket 4, an inner jacket 3, a front plate 5, a rear plate 8, an electric heater 2, a thermal resistor 11, a jacket 9, an inner rib plate 6, a fusible plug 10, and a protective cover 1 , vapor chamber 7 and expander 12.

[0019] The outer cover 4 and the inner cover 3 are cylindrical, and the outer cover 4 is set on the outer side of the inner cover 3 . The front plate 5 is a circular plate, and the middle part of the front plate 5 is provided with a positioning surface C, through which the heat setting roller is connected with the outside; the rear plate 8 is a ring plate. The front and rear ends of the outer sleeve 4 and the inner sleeve 5 are fixedly connected with the front plate 5 and the rear plate 8 respectively to form the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com