Metallic bipolar plate shaped by sheet-metal press working

A forming metal and sheet metal stamping technology, which is applied in the direction of fuel cells, battery electrodes, fuel cell grouping, etc., can solve problems such as difficulty in fixing metal mesh, difficulty in realizing stamped plate structure, difficulty in matching batteries evenly with multi-layer mesh, etc. Achieve the effects of increasing the effective use area, increasing the specific power of volume and specific power of mass, and reducing its own weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

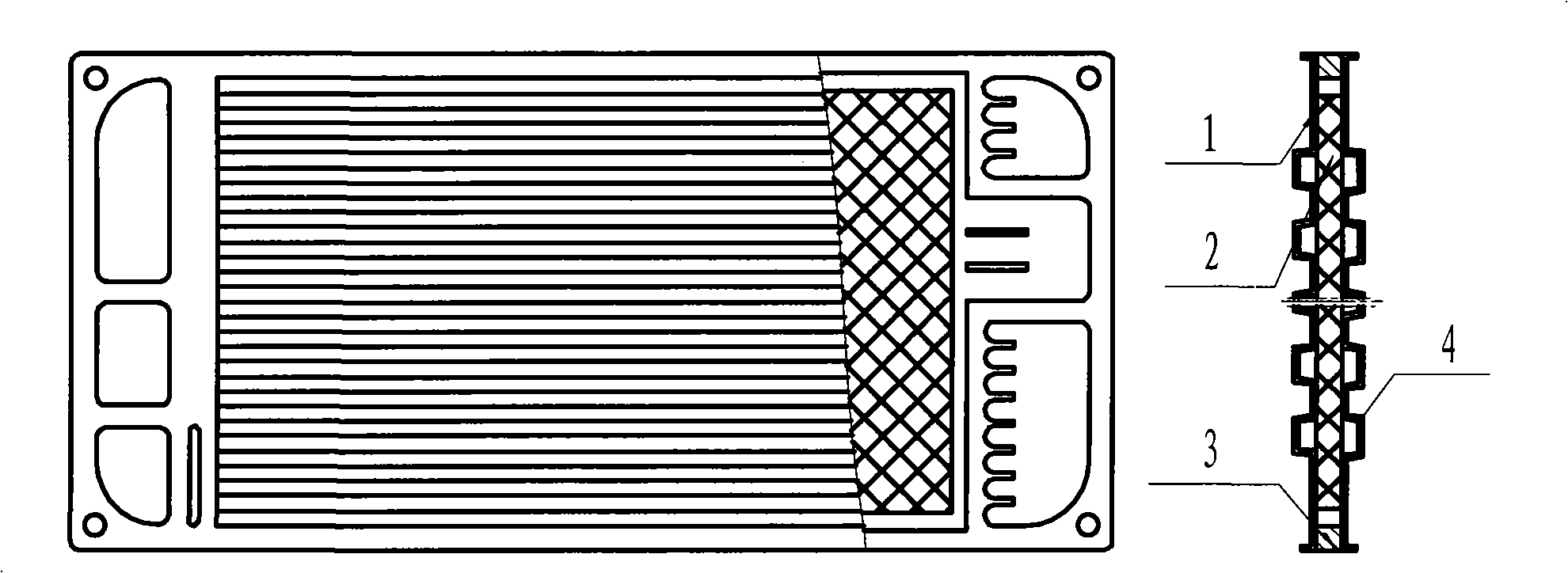

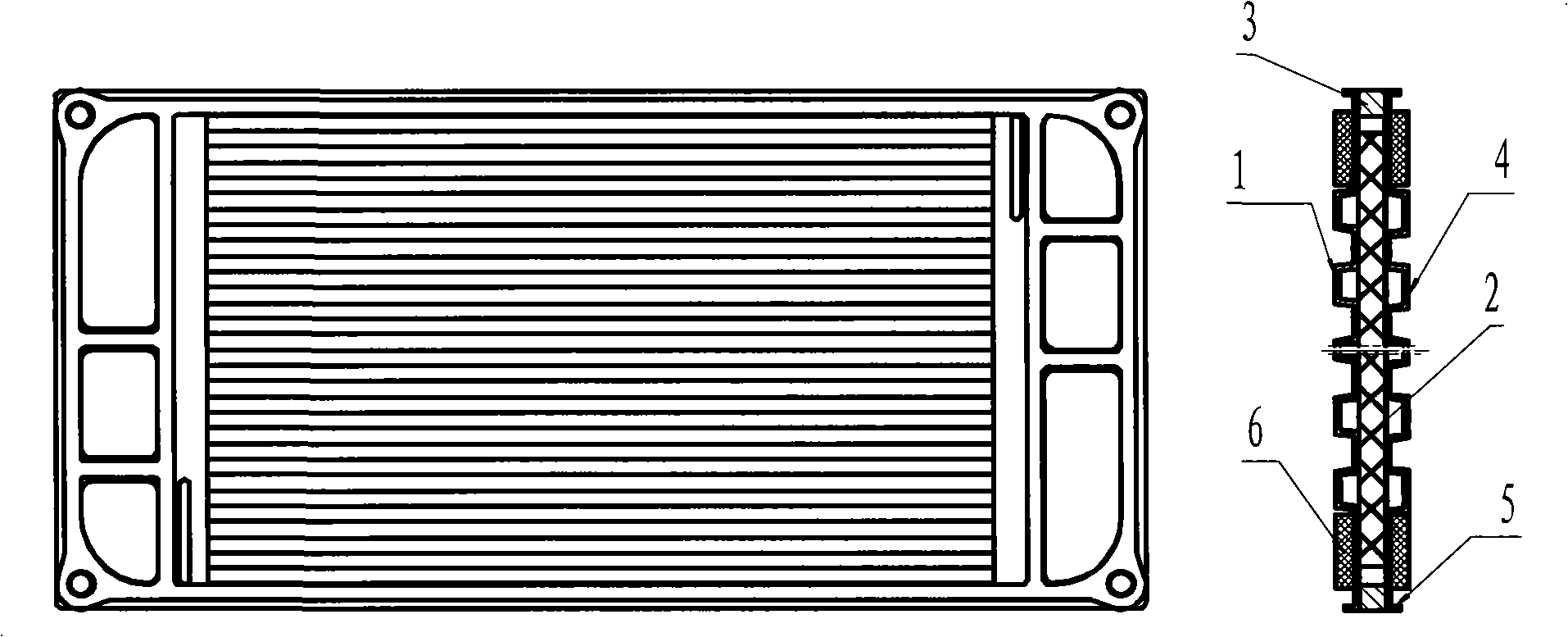

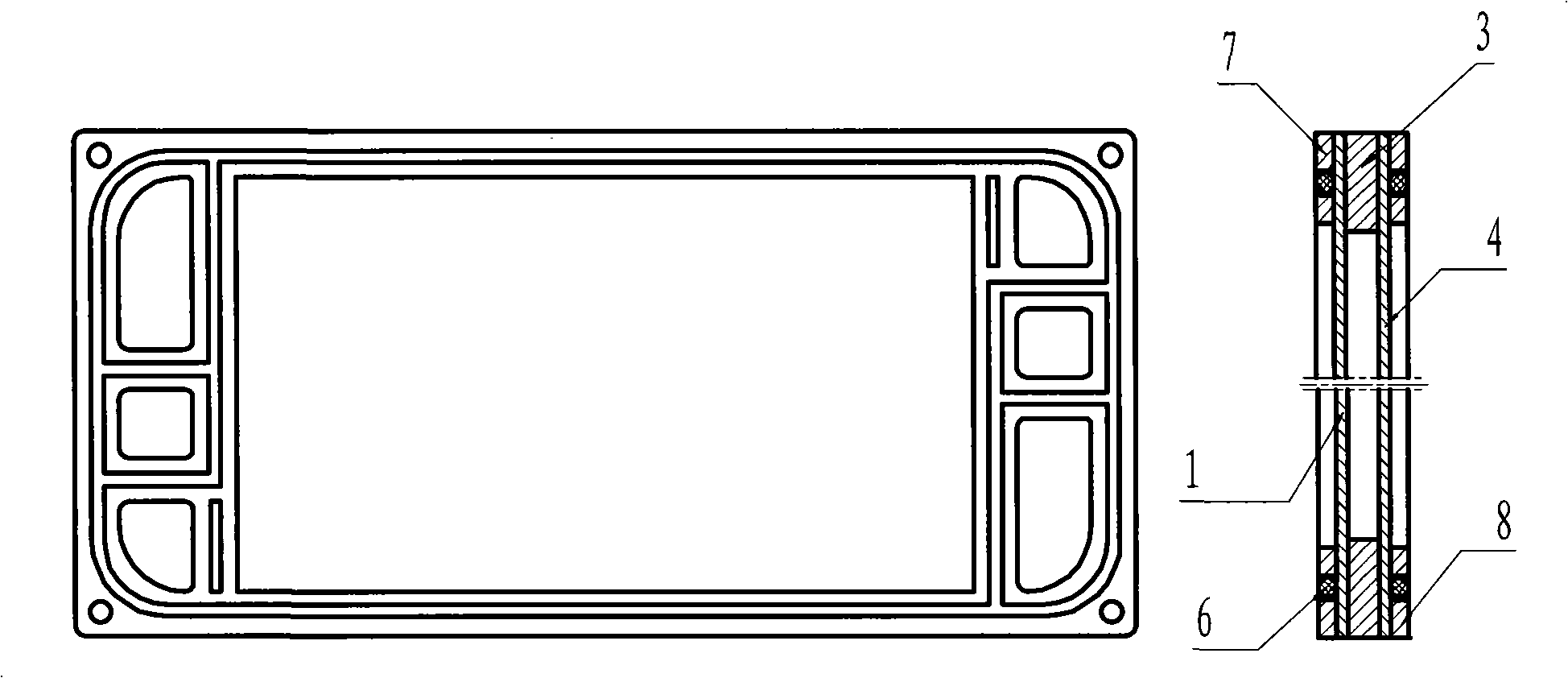

[0029] A metal bipolar plate stamped and formed from sheet metal, such as figure 1 As shown, it consists of four parts, including a metal anode unipolar plate 4 (an anode flow field is formed on its outer surface, which can be independently optimized), a metal cathode unipolar plate 1 (a cathode flow field is formed on its outer surface, can be independently optimized), and there is no water channel function on the two unipolar plates; between the anode unipolar plate and the cathode unipolar plate, there is a flow field for maintaining the discharge water with a certain channel width, and each fluid enters the flow field The water frame 3 of the interface area of the channel is filled with a stretched metal mesh as a draining hot water flow field to form a water flow field 2 (the flow field structure can be optimized independently); the four parts can be combined by bonding or welding Together.

[0030] The anode unipolar plate and the cathode unipolar plate are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com