Dielectric ceramic thin film containing Nb composite metal oxide and preparation method thereof

A composite metal and dielectric ceramic technology, applied in circuits, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of unstable chemical properties, limit the development of microwave thin-film devices, etc. Controllable ingredients, high quality, and integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-Ca

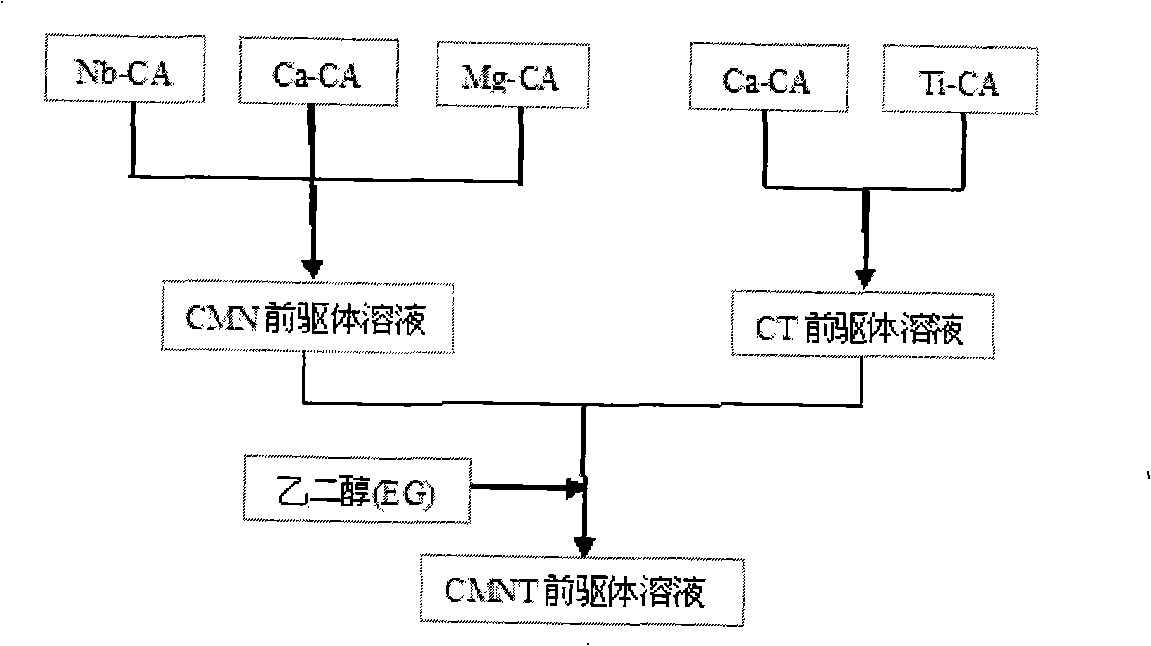

[0056] The present invention is further described below with two specific examples, and the present invention is not limited to this example. Example 1 - Ca[Ti 1 / 3 (Mg 1 / 3 Nb 2 / 3 ) 2 / 3 ]O 3 Preparation of Dielectric Ceramic Thin Films

[0057] Molar ratio to CaCO 3 :CA=1:1, MgCO 3 : CA=1:1, weigh CaCO 3 , MgCO 3 and citric acid (CA), first dissolve citric acid in deionized water to make citric acid solution, dissolve CaCO 3 Use a 0.25 mol / L citric acid solution to dissolve MgCO 3 Use a 2 mol / L citric acid solution, then add CaCO 3 , MgCO 3 , stirred until clear to obtain Ca-CA solution and Mg-CA) solution.

[0058] Weigh tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) and CA, first dissolve CA in deionized water to make a CA solution with a concentration of 0.1 mol / L, stir at 80°C until clear, then pour the hot solution of CA into Ti(OC 4 h 9 ) 4 , continue stirring at 80° C. for 2 to 3 hours to obtain a clear Ti-CA solution with a constant volume of 0.1 mol / L.

[00...

Embodiment 2

[0063] Example 2-Ca(Mg 1 / 3 Nb 2 / 3 )O 3 Preparation of Dielectric Ceramic Thin Films.

[0064] Clarified Ca-CA (0.2 mol / liter), Mg-CA solution (2 mol / liter) and Nb-CA solution (0.7 mol / liter) were configured in the same manner as in Example 1. Pour the prepared Ca-CA solution and Mg-CA solution into the Nb-CA solution, adjust the pH of the solution to 8 with ammonia water, and add ethylene glycol (EG) 6 times the total amount of citric acid in the solution as a cross-linking agent , and then slowly heated and stirred at 40°C to concentrate to 0.1 mol / liter containing CMN precursor, after standing and aging, you can get Ca(Mg 1 / 3 Nb 2 / 3 )O 3 (CMN) precursor solution. Coating and heat treatment by the same method in Example 1, obtain a single perovskite structure, Ca(Mg 1 / 3 Nb 2 / 3 )O 3 Dielectric ceramic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com