Technique for joint production of methanol and natural gas with methyl hydride containing synthesis gas

A technology for methane synthesis gas and natural gas, which is applied in the fields of gas fuel, organic chemistry, petroleum industry, etc., can solve the problems of large power consumption, large benefit impact, large investment, etc., and achieve the effect of increasing power consumption, increasing raw materials, and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

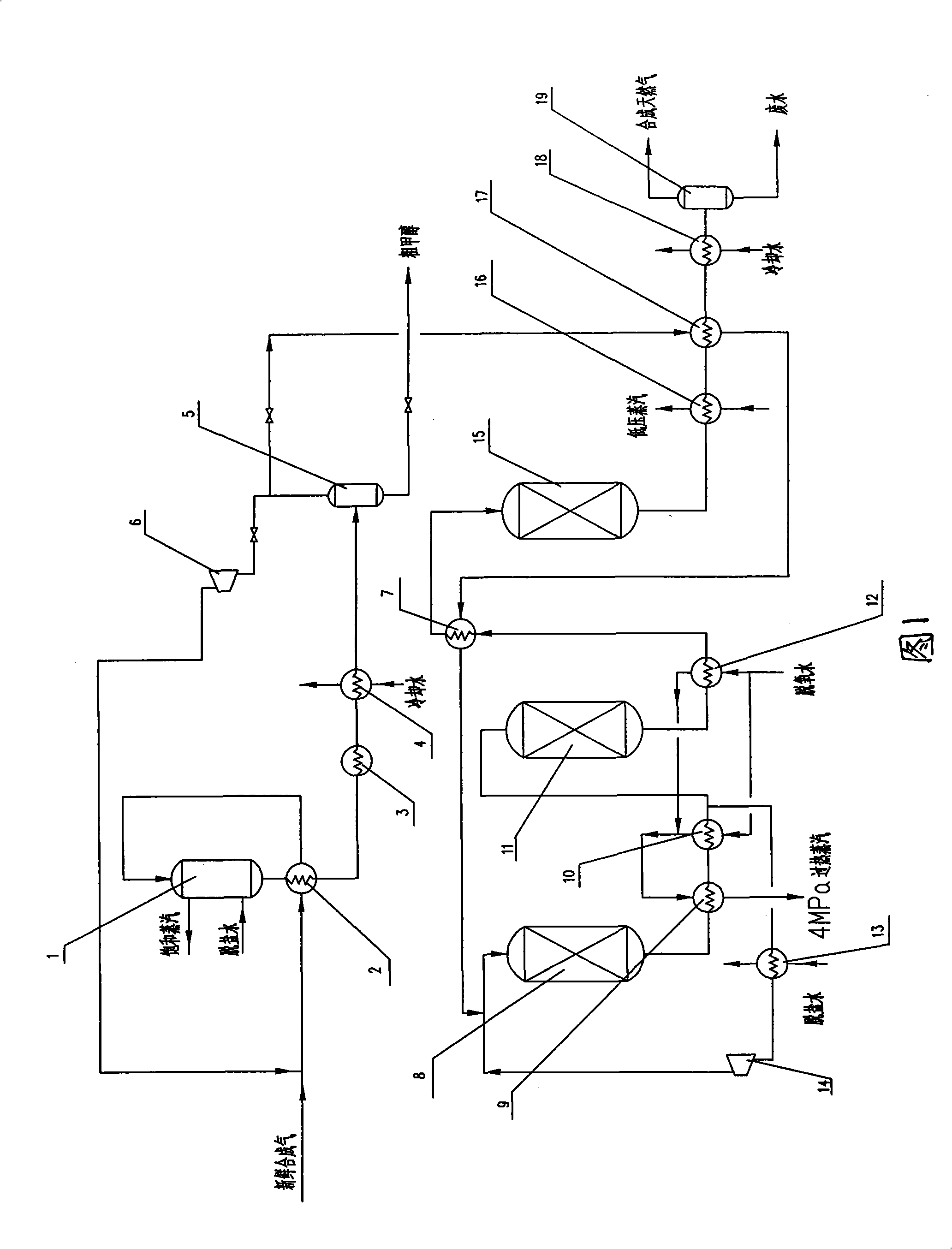

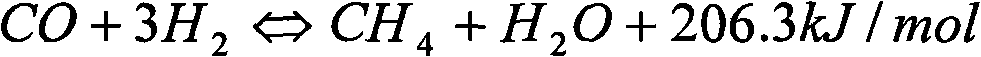

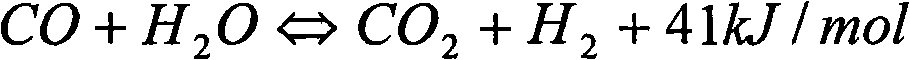

[0017] Below in conjunction with Fig. 1, the present invention is described in further detail, a kind of methane-containing synthesis gas co-production methanol and natural gas technology, methane-containing synthesis gas (H 2 , CO, CO 2 、CH 4 ) is pressurized to about 7MPa(a) with a synthesis gas compressor, and then mixed with the circulating gas from the methanol synthesis tower 1. The mixed gas passes through the gas-gas heat exchanger 2 to exchange heat to 220-230°C, and then enters the methanol synthesis Tower 1 synthesizes methanol, and the methanol-containing gas exiting methanol synthesis tower 1 and the mixed gas entering the tower exchange heat in gas-gas heat exchanger 2, then pass through air cooler 3 and water cooler 4 to finally cool the gas to 40°C, and methanol is condensed into The liquid is separated in the methanol separator 5, and part of the gas separated from the methanol enters the methane synthesis unit as a relaxation gas, and the other part is press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com