Basement bottom plate rear pouring tape construction method

A basement floor and construction method technology, applied in the direction of basic structure engineering, building components, protective devices, etc., can solve the problems of construction quality impact, effort, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

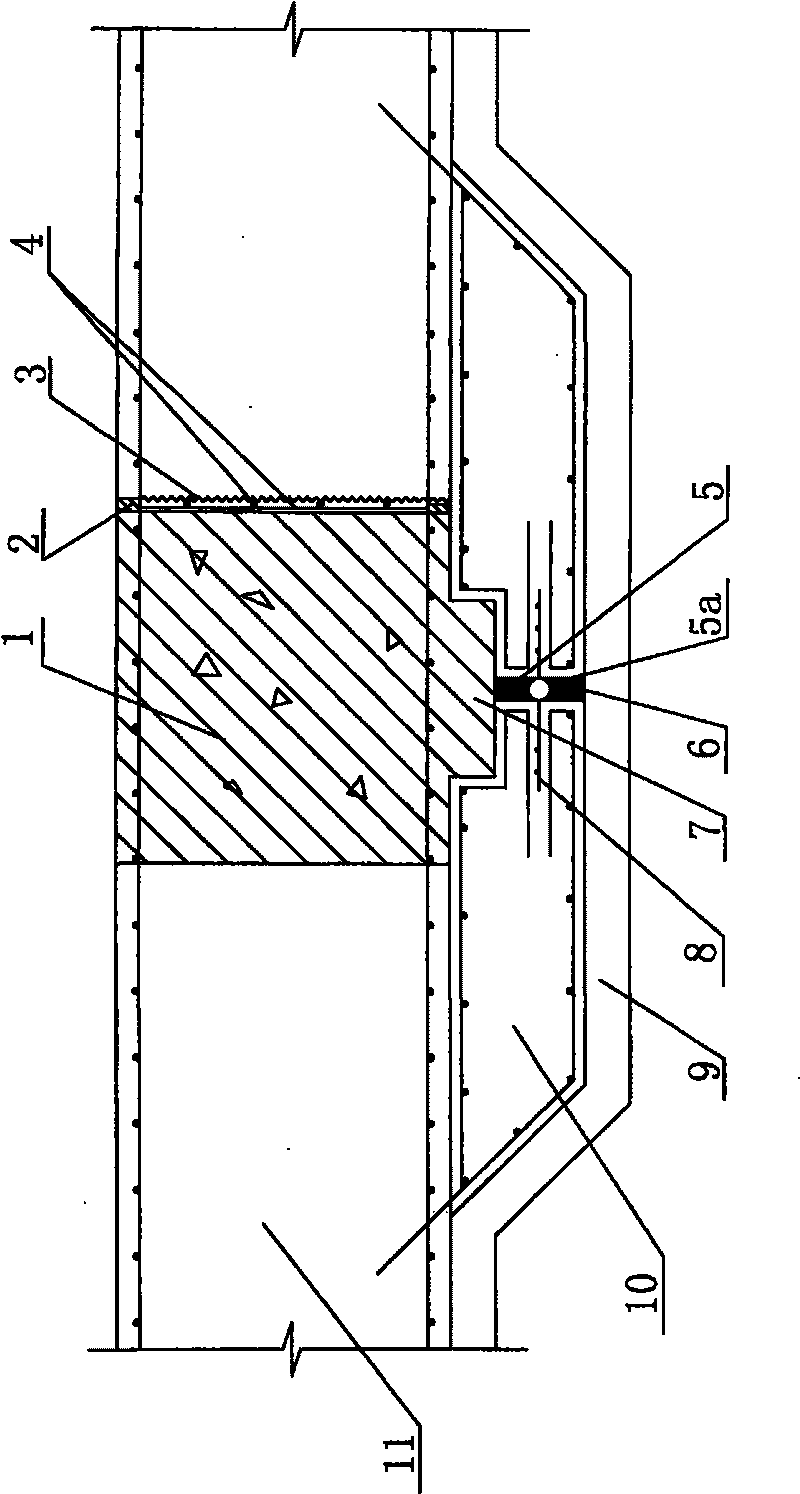

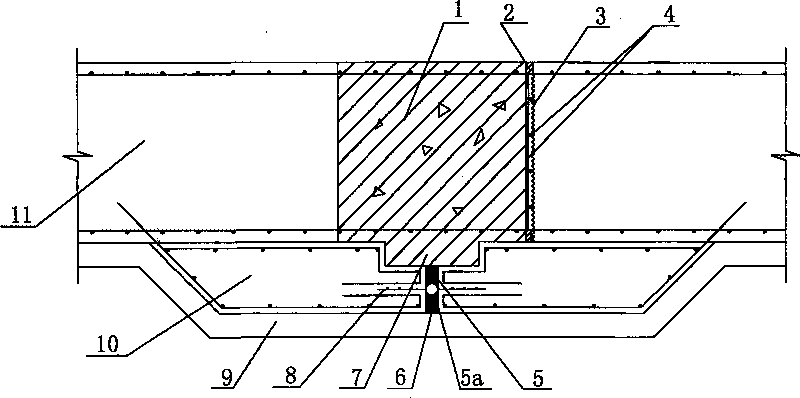

[0021] The present invention will be further described below in conjunction with the drawings, and specific implementations will be given.

[0022] The steps of the basement floor post-pouring belt construction method are: the basement floor post-pouring belt construction method is characterized by including the following steps: 1) The plain concrete cushion 9 is extended and poured under the post-pouring belt 1, with large height errors or Defects should be corrected and flattened; 2) Reinforced cushion 10 and corresponding drainage ditch 7 and expansion joints 6 should be poured on top of plain concrete cushion 9; Sewage drainage ditch 7 and expansion joint 6 are matched in the middle of cushion layer 10, rubber waterstop 8 is placed at expansion joint 6, and the corresponding sides of sewage ditch 7 and expansion joint 6 are moulded, and the side reinforced cushion layer 10 is poured; b .Remove the template on one side of the sewage ditch 7, the expansion joint 6, and place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com