Dye pesticide waste water reverse osmosis-nanofiltration combined membrane separation material recovery process and apparatus

A pesticide wastewater and reverse osmosis technology, applied in the field of environmental engineering, can solve problems such as low treatment efficiency, high salt content, and difficult biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

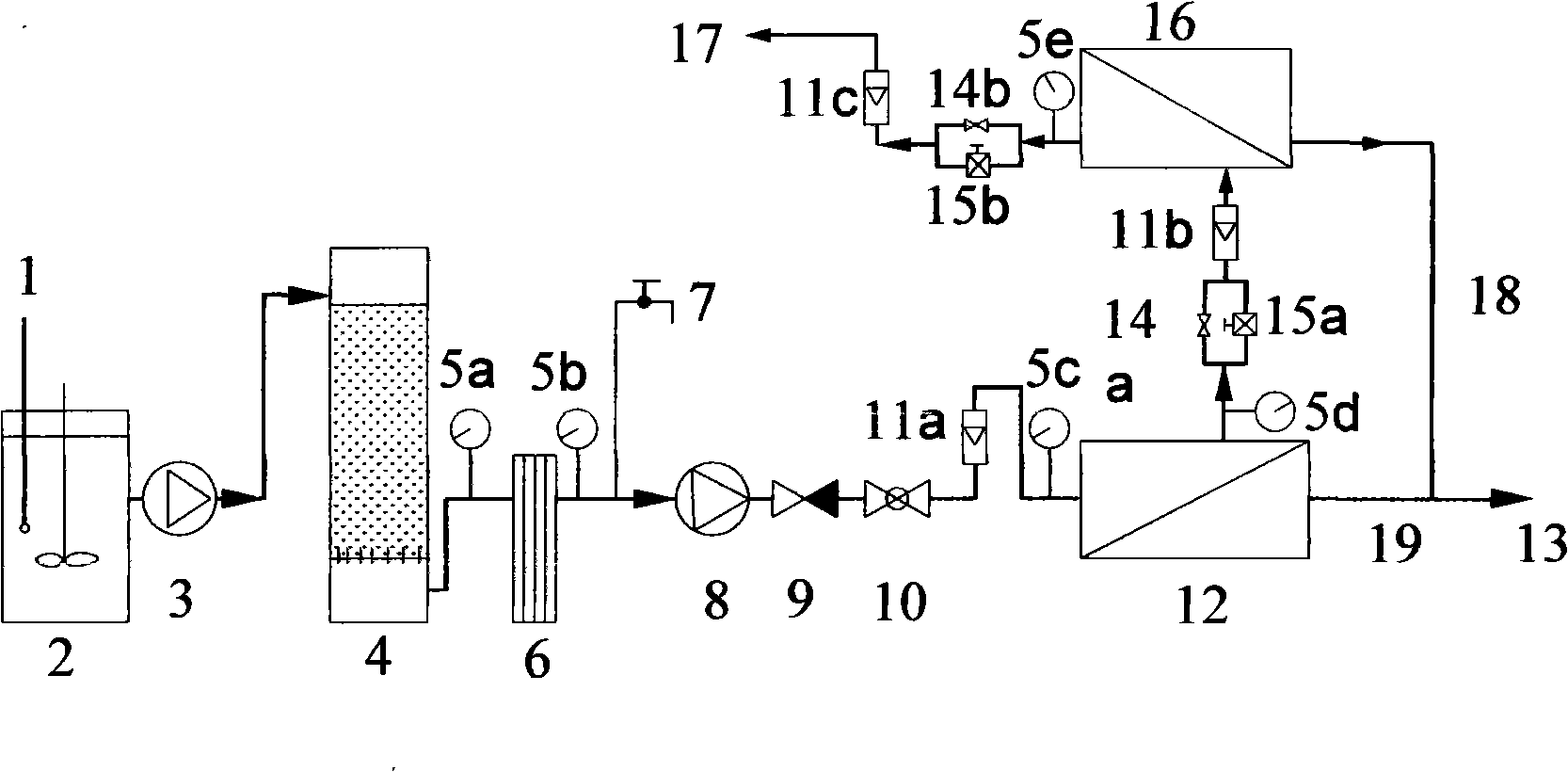

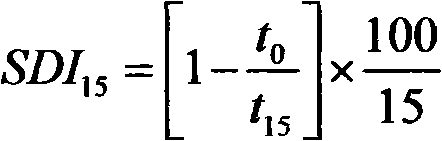

[0010] A dye and pesticide wastewater reverse osmosis-nanofiltration combined membrane separation material recovery process, the process steps are: under the water temperature condition of 25-35 ℃, the pH value of the wastewater to be treated in the storage tank is adjusted to 6.5-9.0; the wastewater is increased After pressing, it enters the media filter to remove suspended solids with a particle size > 1 mm. The filler in the media filter is quartz sand or ceramsite with a particle size of 0.5-1.2 mm; 1μm colloid, and the sedimentation index of the effluent is controlled to be -10 Inorganic salts and organic matter on the order of m, the operating pressure of the reverse osmosis device is 1.0-2.0 MPa, and the material of the reverse osmosis membrane is polyamide; MPa, the removal particle size is 10 -9 Divalent salts and organic matter on the order of m, recover dyes, pesticides and related intermediates in the effluent, and use polyamide as the nanofiltration membrane mater...

Embodiment 2

[0012] A device for dye and pesticide wastewater reverse osmosis-nanofiltration combined membrane separation material recovery process, the device includes a water storage tank 2, a media filter 4, a microfilter 6, a reverse osmosis device 12 and a nanofilter 16, the device is composed of an inlet and outlet water pipe Sequential connection, a pH adjustment device 1 is installed in the water storage tank, a booster pump 3 is installed between the water storage tank and the medium filter, and a first pressure gauge 5a and a second pressure gauge are respectively installed on the water inlet and outlet pipes at both ends of the microfilter 5b, a sampling port 7, a high pressure pump 8, a one-way valve 9, a ball valve 10 and a flow meter 11a are sequentially arranged between the second pressure gauge 5b on the outlet pipe of the microfilter and the reverse osmosis device, the water inlet pipe of the reverse osmosis device and the concentrated A third pressure gauge 5c and a fourth...

Embodiment 3

[0014] The relevant parameters of media filtration, MF, RO and NF are as follows:

[0015] parameters

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com